Design, construction and operation of the ProtoDUNE-SP Liquid Argon TPC

Abstract

The ProtoDUNE-SP detector is a single-phase liquid argon time projection chamber (LArTPC) that was constructed and operated in the CERN North Area at the end of the H4 beamline. This detector is a prototype for the first far detector module of the Deep Underground Neutrino Experiment (DUNE), which will be constructed at the Sandford Underground Research Facility (SURF) in Lead, South Dakota, USA. The ProtoDUNE-SP detector incorporates full-size components as designed for DUNE and has an active volume of m3. The H4 beam delivers incident particles with well-measured momenta and high-purity particle identification. ProtoDUNE-SP’s successful operation between 2018 and 2020 demonstrates the effectiveness of the single-phase far detector design. This paper describes the design, construction, assembly and operation of the detector components.

1 Introduction

1.1 ProtoDUNE-SP in the Context of DUNE

The Deep Underground Neutrino Experiment (DUNE) will be a world-class neutrino observatory and nucleon decay detector designed to answer fundamental questions about elementary particles and their role in the universe. The international DUNE experiment, hosted by the U.S. Department of Energy’s Fermilab, uses a near detector located at Fermilab and a far detector, 1300 km away, located approximately 1.5 km underground at the Sanford Underground Research Facility (SURF) in South Dakota, USA. The far detector will be a very large LArTPC with a fiducial mass of 40 kt (total mass 68 kt) of liquid argon (LAr), split into four modules. DUNE has been pursuing two LArTPC technologies, single-phase (liquid only) and dual-phase (liquid and gas); this paper describes ProtoDUNE-SP, a prototype for a single-phase (SP) detector module.

Construction of ProtoDUNE-SP was proposed to the CERN Super Proton Synchrotron Committee (SPSC) in June 2015 [1] and, following positive recommendations by SPSC and the CERN Research Board in December 2015, was approved at CERN as experiment NP-04. ProtoDUNE-SP has since been constructed and successfully operated at the CERN Neutrino Platform (NP). The design of the ProtoDUNE-SP detector has been documented in a Technical Design Report [2].

ProtoDUNE-SP prototypes most of the components of a DUNE single-phase far detector module at 1:1 scale, with an extrapolation of about 1:20 in total LAr mass. With a total LAr mass of 0.77 kt, it represents the largest monolithic single-phase LArTPC detector built to date, and is a significant experiment in its own right.

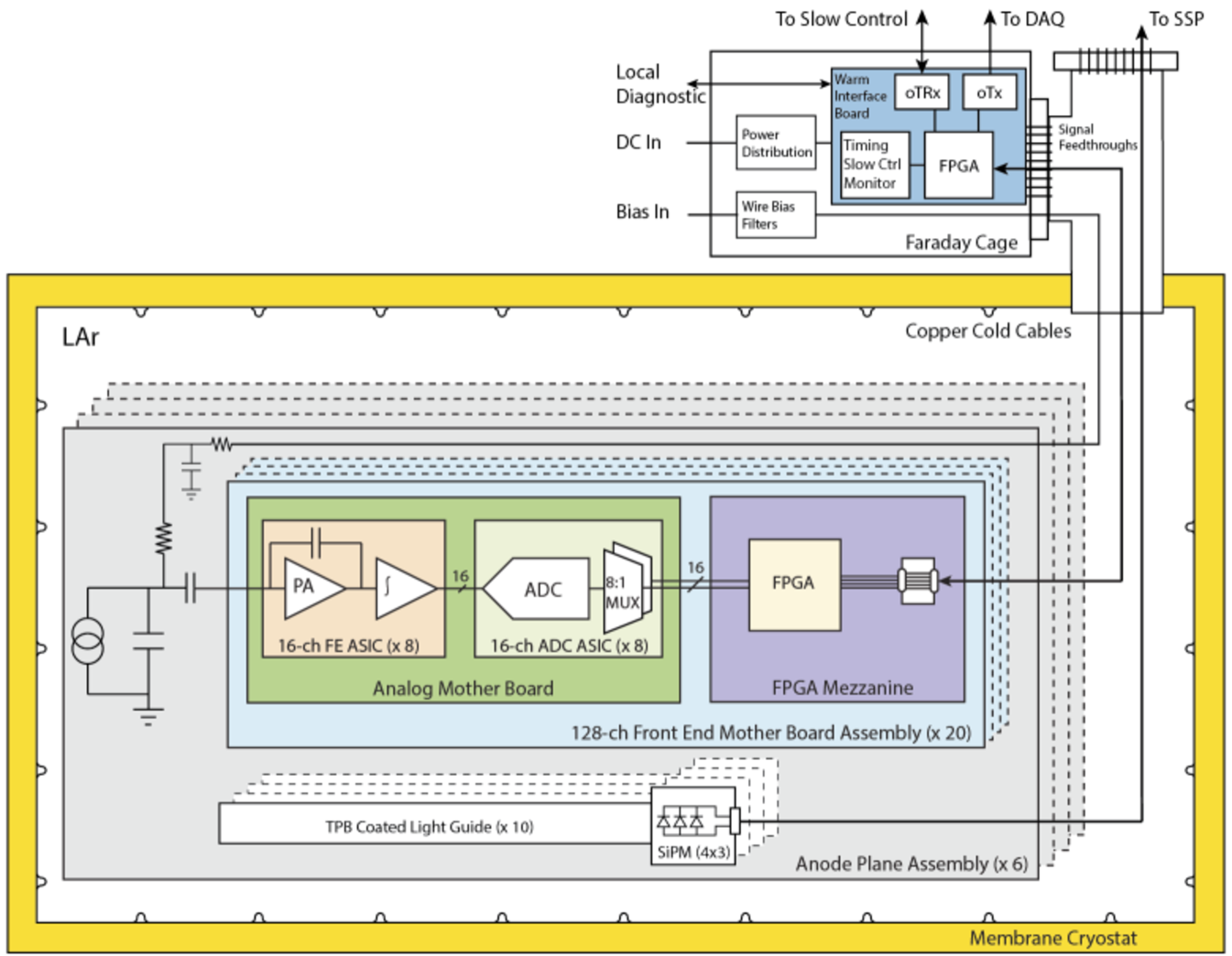

The ProtoDUNE-SP detector elements, the time projection chamber (TPC), the cold electronics (CE), and the photon detection system (PDS), are immersed in a cryostat filled with the LAr target material. The TPC consists of two vertical anode planes, one vertical cathode plane, and a surrounding field cage. A cryogenics system maintains the LAr at a stable temperature of about 87 K and at the required purity level through a closed-loop process that recovers the evaporated argon, recondenses, filters, and returns it to the cryostat.

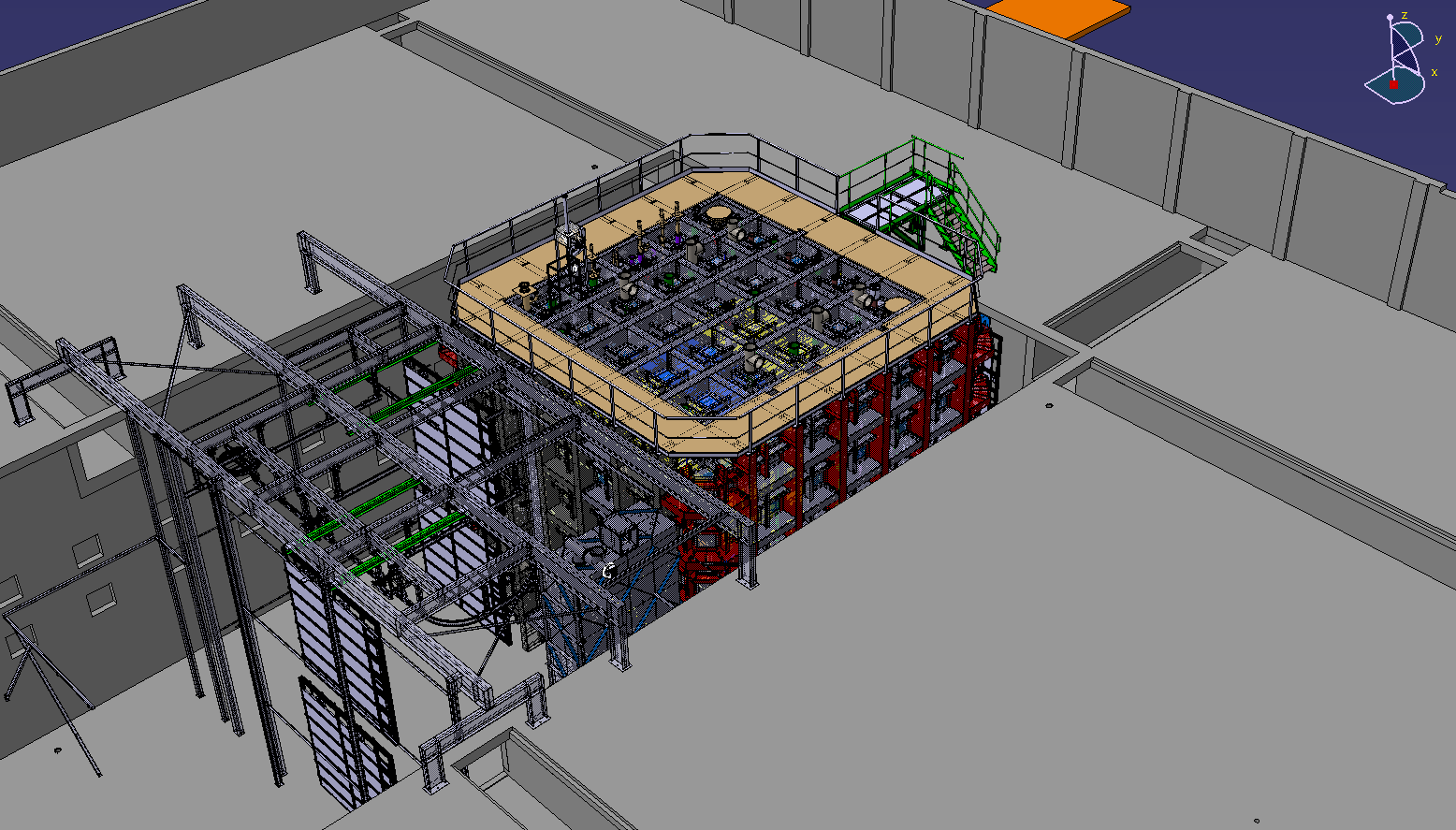

ProtoDUNE-SP is located in an extension to the EHN1 hall (Experimental Hall North 1 - EHN1) in CERN’s North Area, where a new, dedicated charged-particle test beamline was constructed as part of the CERN NP program. Construction and installation of ProtoDUNE-SP was completed in early July 2018. Filling with LAr and commissioning took place in July and August of that year. First beam was delivered to EHN1 on August 29, 2018 and the beam run was completed on November 11, 2018. The detector continued to operate through July 19, 2020, collecting data to test and validate the technologies for the future DUNE far detector modules, demonstrate operational stability, and explore operational parameters.

The construction, installation, and operation of the ProtoDUNE-SP detector, as described in this paper, has validated the design elements of the single-phase technology, the membrane cryostat technology and associated cryogenics systems, as well as instrumentation, data acquisition, and detector control. First performance results are presented in a separate paper [3].

1.2 Cryostat and Cryogenics

ProtoDUNE-SP implements the first large-dimension prototype cryostat built for a particle physics detector based on the technology used for liquefied natural gas (LNG) storage and transport. Its construction and operation serves as a validation of the membrane cryostat technology and associated cryogenics. The ProtoDUNE-SP cryostat was constructed in EHN1 without any mechanical attachment to the floor or the building side walls. Its internal dimensions are 8.5 m in width and length and 7.9 m in height. The cryostat and the cryogenics systems are described in detail in Section 3.

1.3 Detector Components

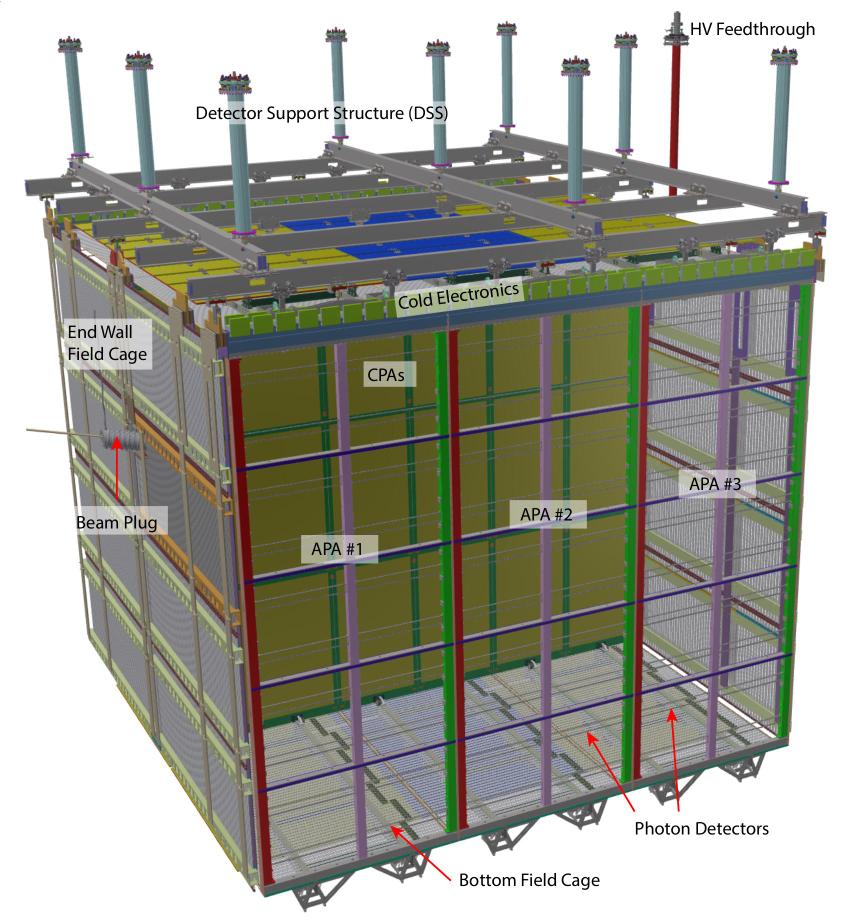

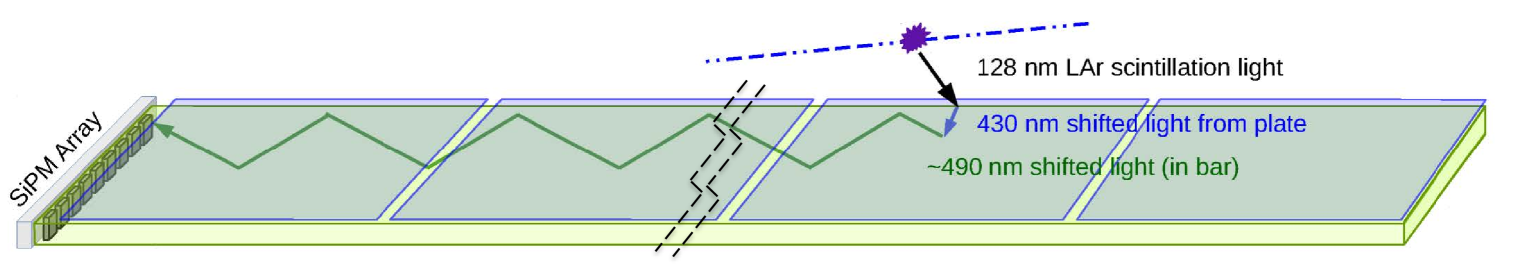

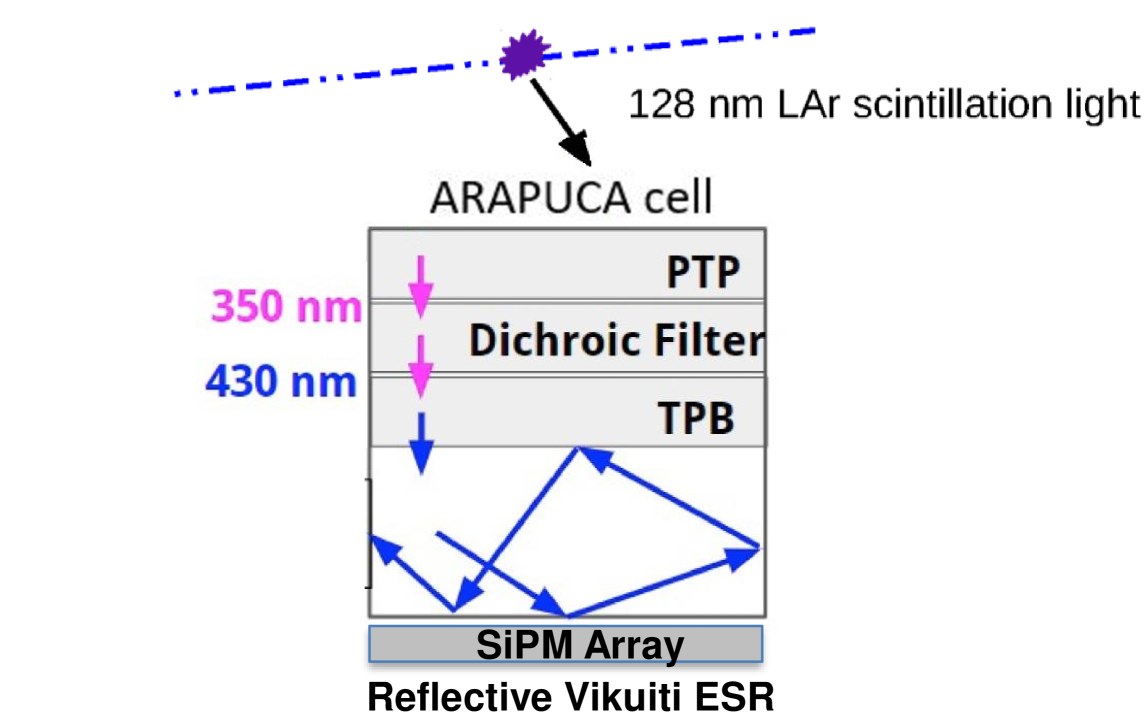

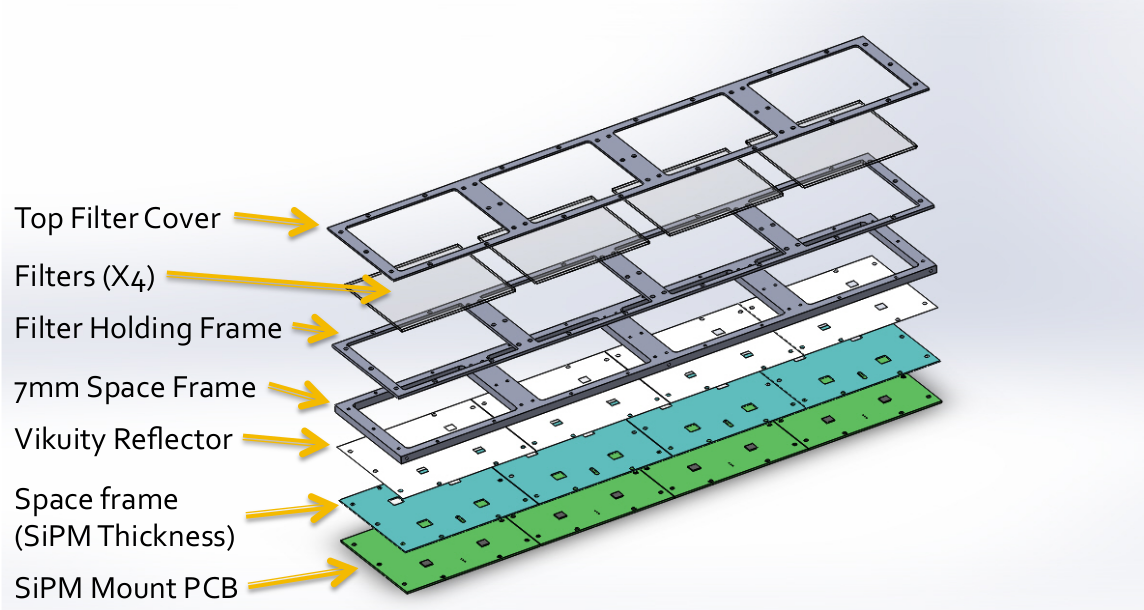

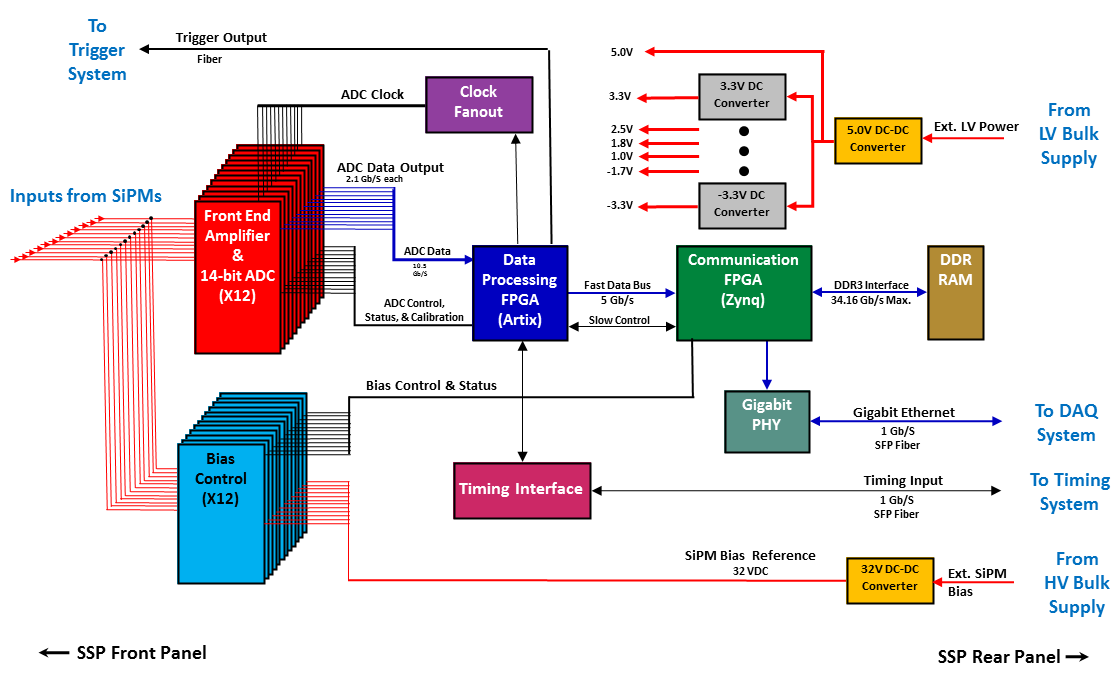

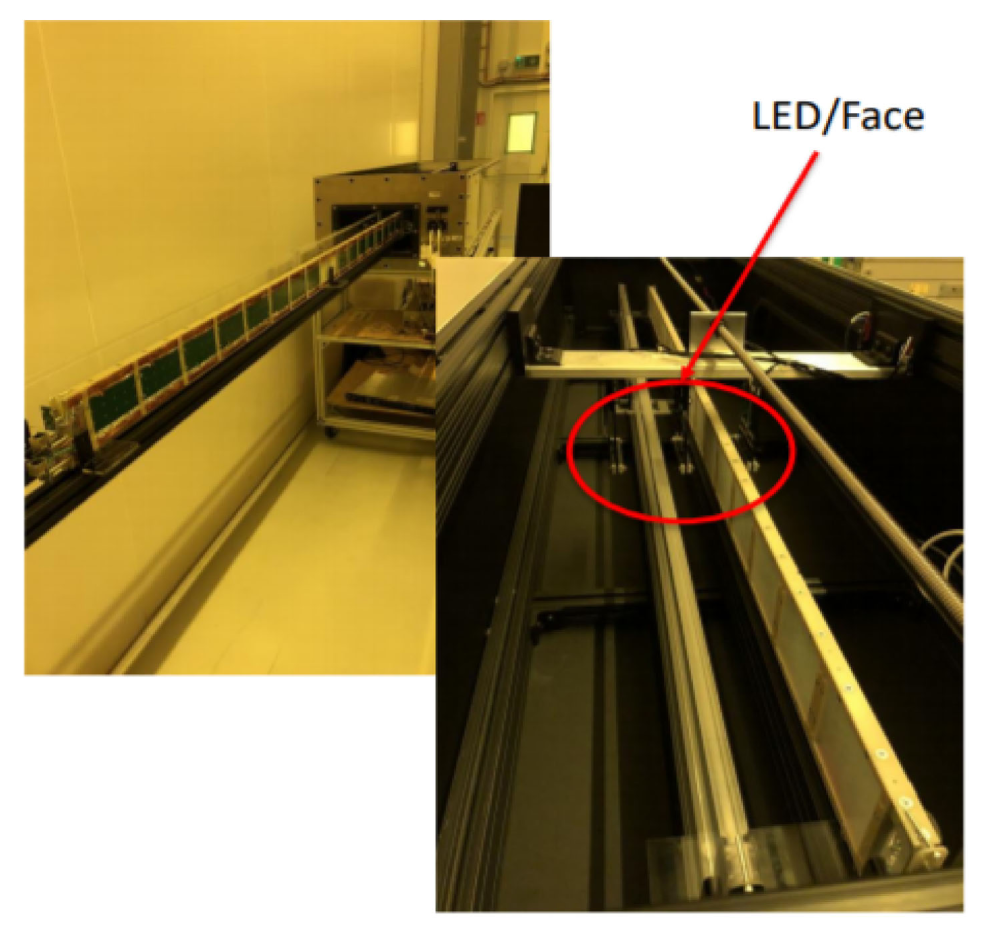

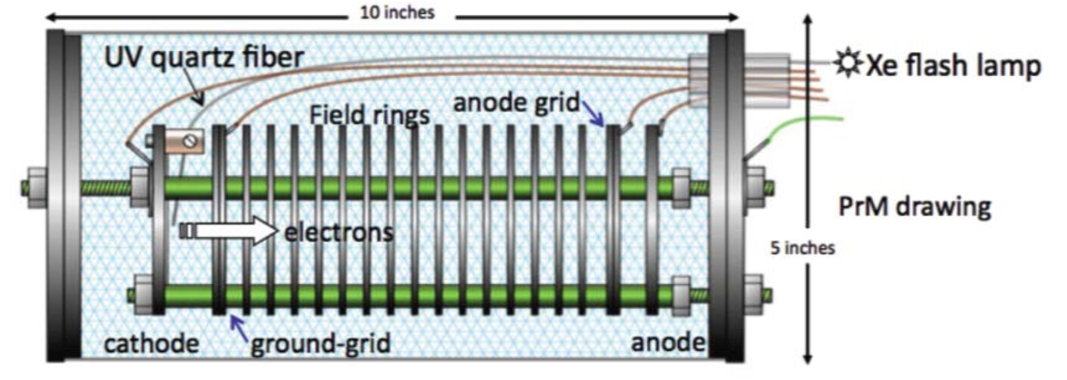

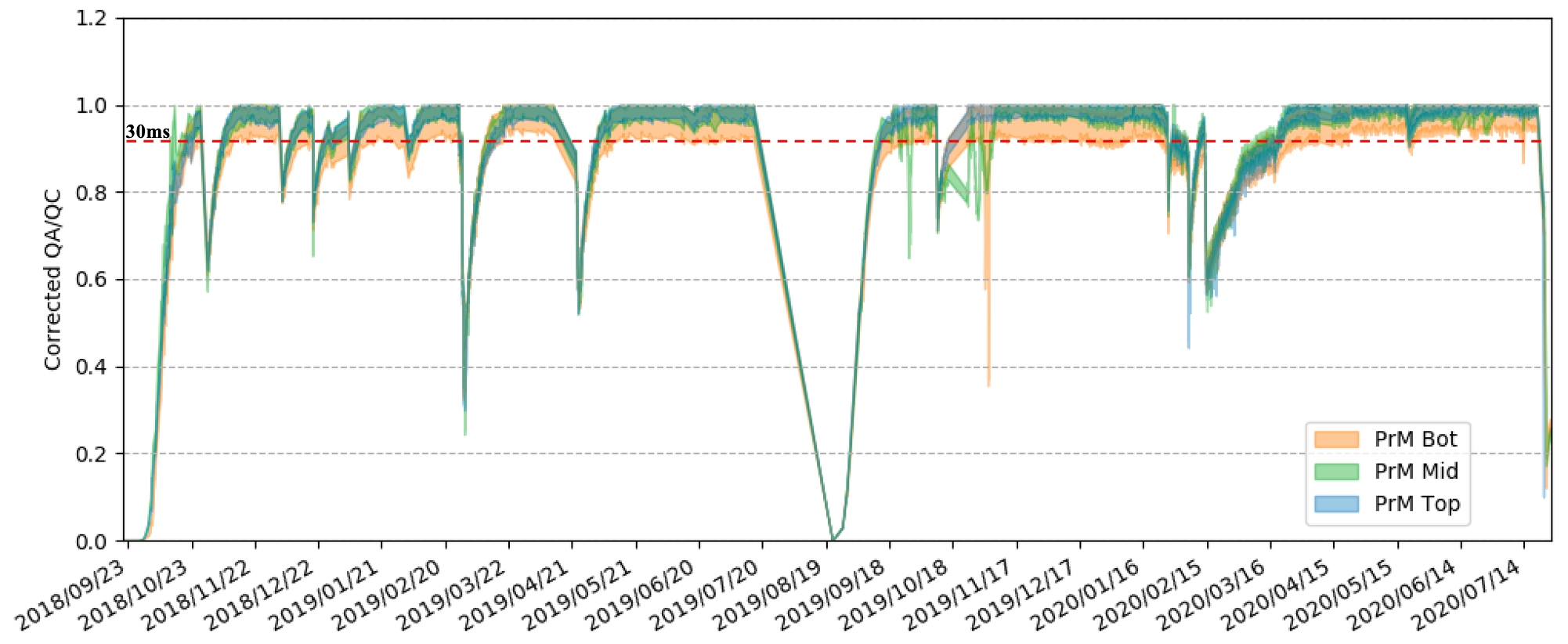

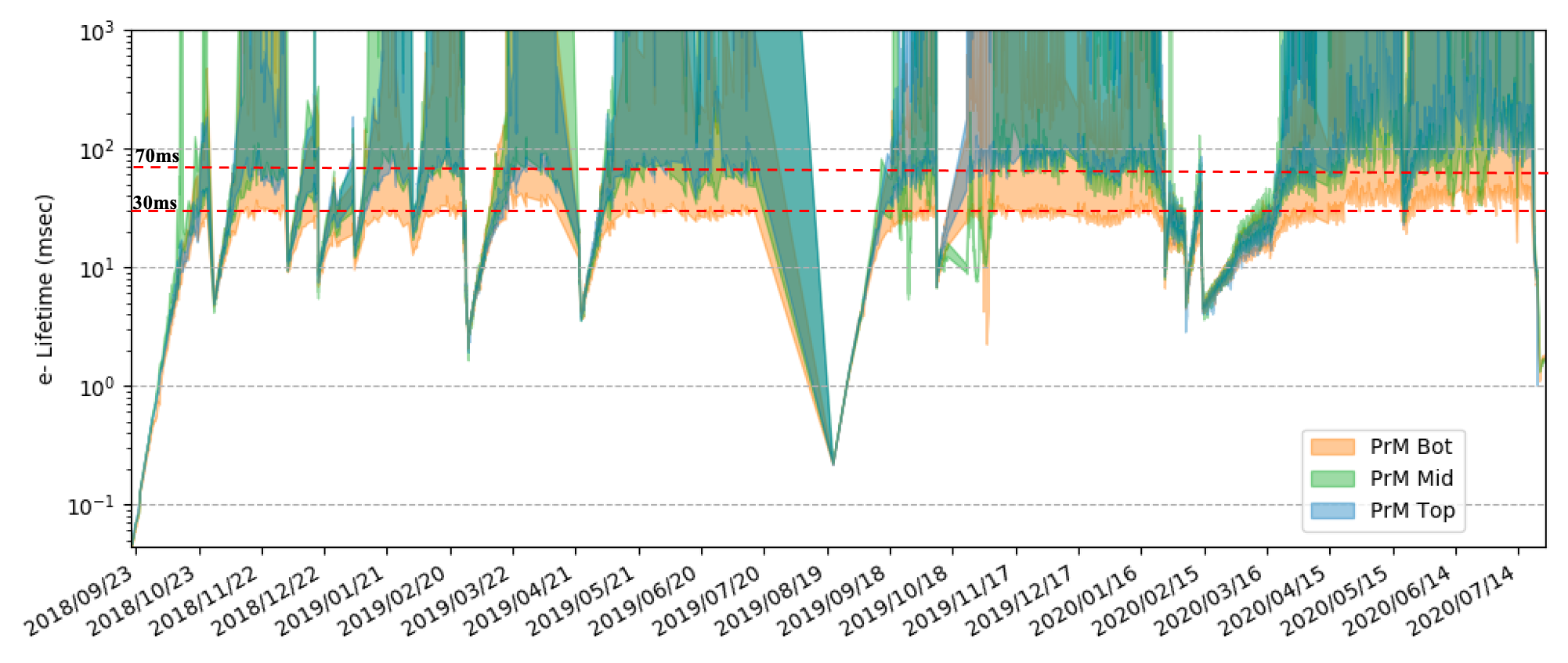

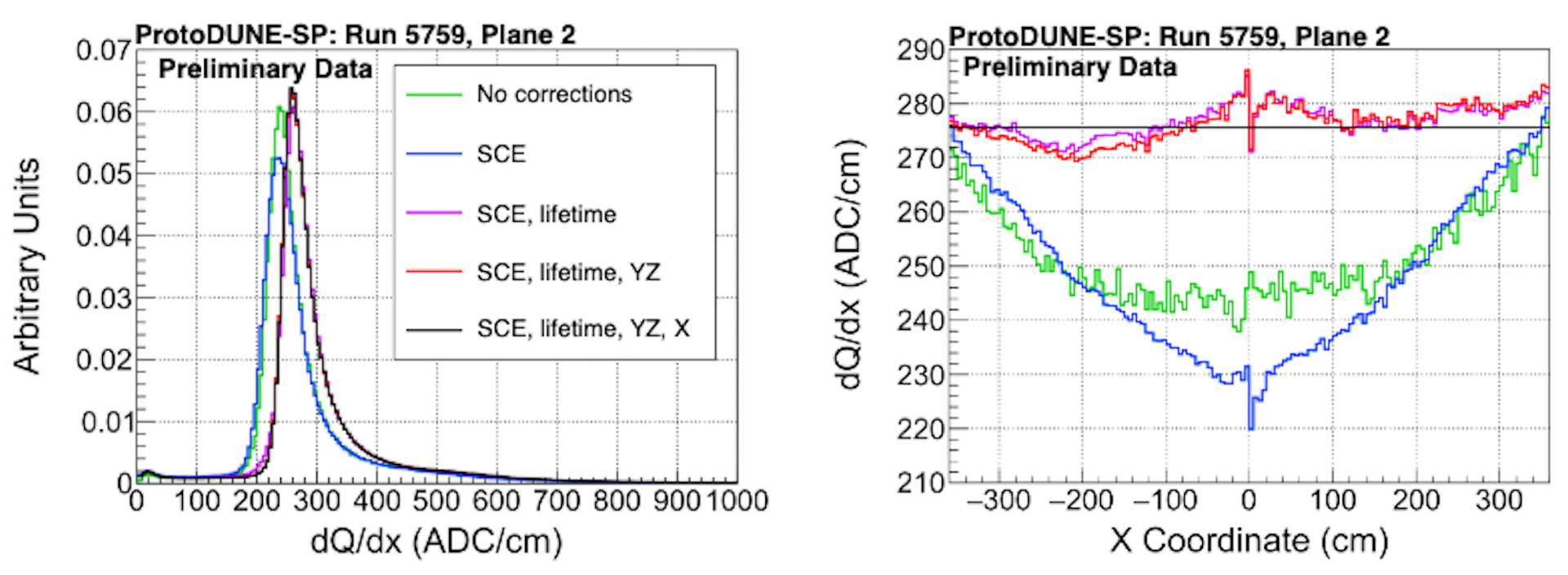

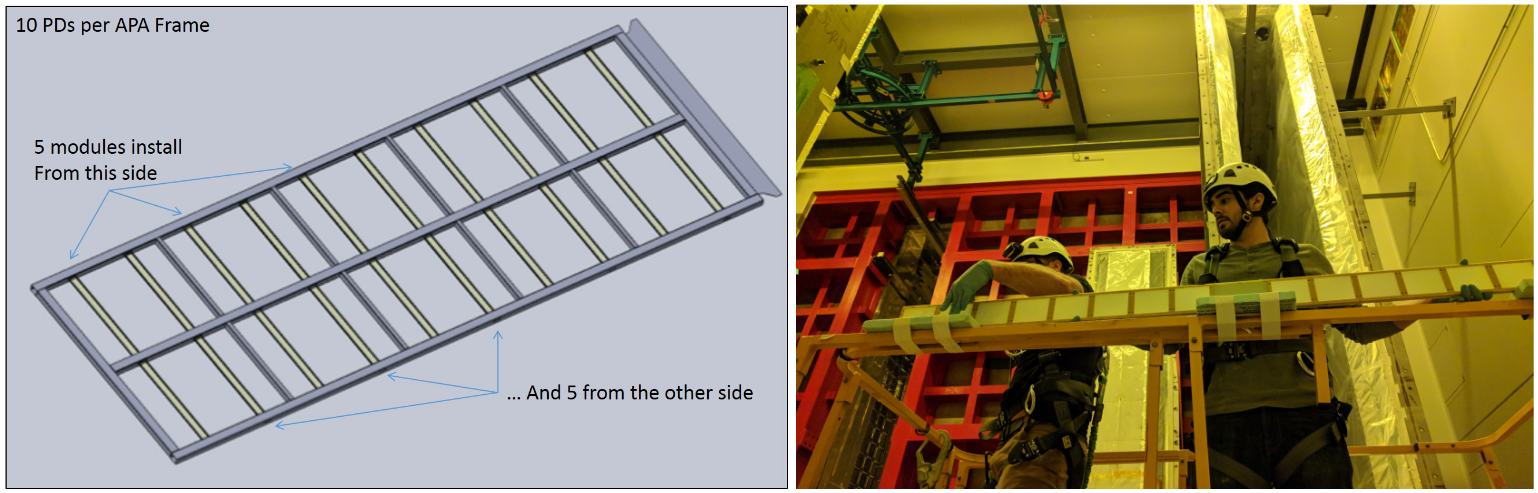

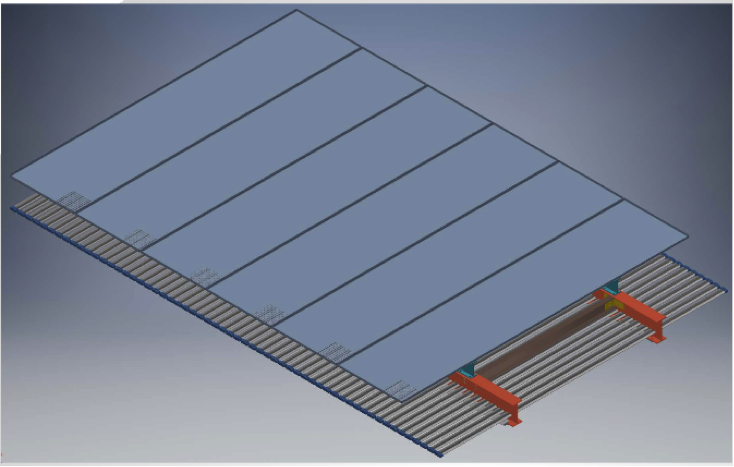

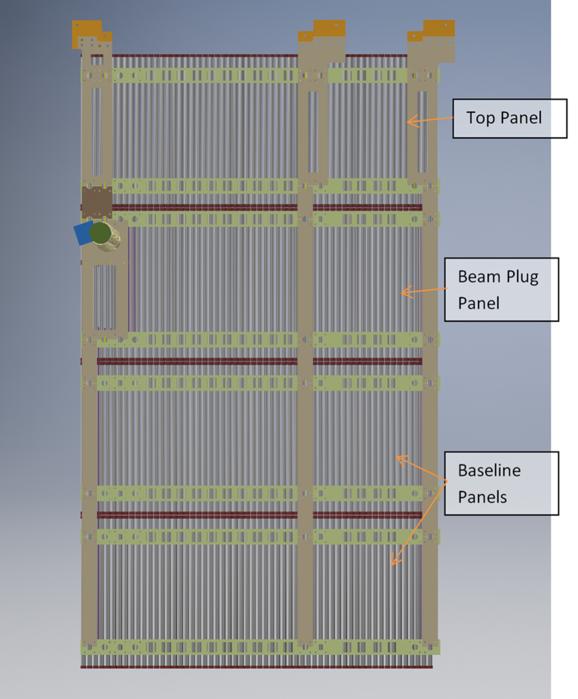

The far detector DUNE-SP TPC components are designed in a modular way so that they can be transported underground. The ProtoDUNE-SP components are therefore also modular. Six Anode Plane Assemblies (APAs) are arranged into the two APA planes in ProtoDUNE-SP, each consisting of three side-by-side APAs. Between them, a central cathode plane, composed of 18 Cathode Plane Assembly (CPA) modules, splits the TPC volume into two electron-drift regions, one on each side of the cathode plane. High voltage (HV) is delivered to the cathode plane by the HV feedthrough. A field cage (FC) completely surrounds the four open sides of the two drift regions to ensure that the electric field within is uniform and unaffected by the presence of the cryostat walls and other nearby conductive structures. The detector dimensions are 7 m along the beam direction ( coordinate), 7.2 m wide in the drift direction ( coordinate), and 6.1 m high ( coordinate). The detector elements are suspended from the cryostat roof by the Detector Support Structure (DSS). The Photon Detection System (PDS) modules are embedded in the APAs. They will collect scintillation light from ionized LAr. Ten bar-shaped photon detectors with dimensions of 8.6 cm (height) 2.2 m (length) and 0.6 cm (thickness) are installed at equally spaced heights within each APA. Three different designs of photon-detector technologies are implemented in ProtoDUNE-SP, all based on light readout by silicon photomultipliers (SiPM). Figure 1 illustrates how these components fit together. Cryogenic instrumentation, including a purity monitor, temperature sensors, and cameras, are located in the space between the cryostat walls and the detector elements. The detector components are described in detail in Section 4, and Section 5 presents a description of how those components were assembled together inside the cryostat.

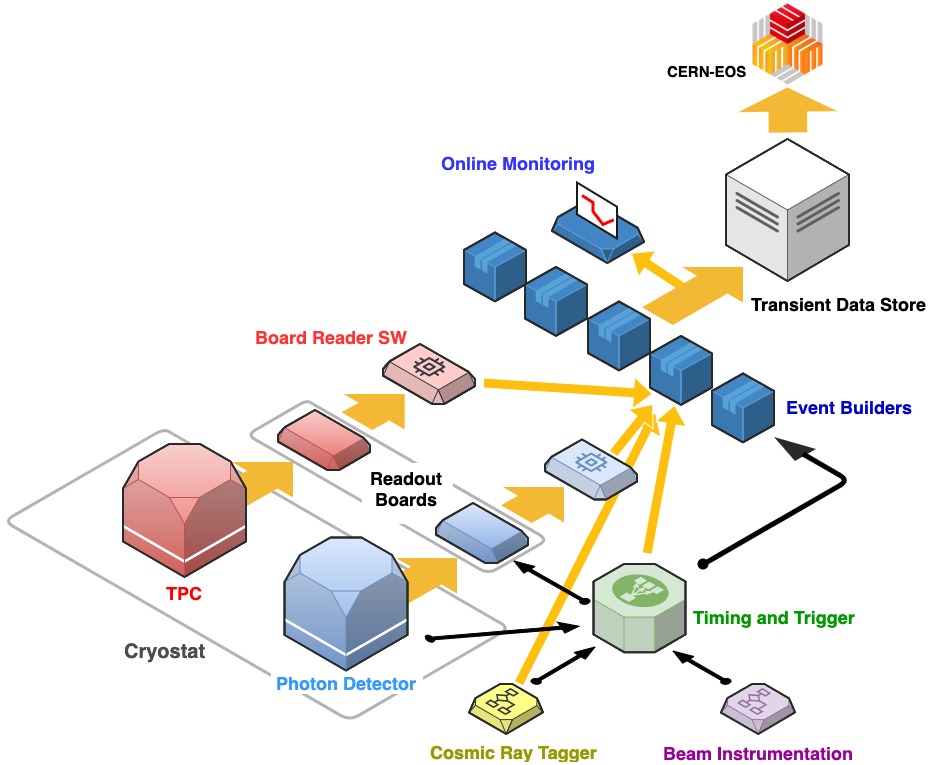

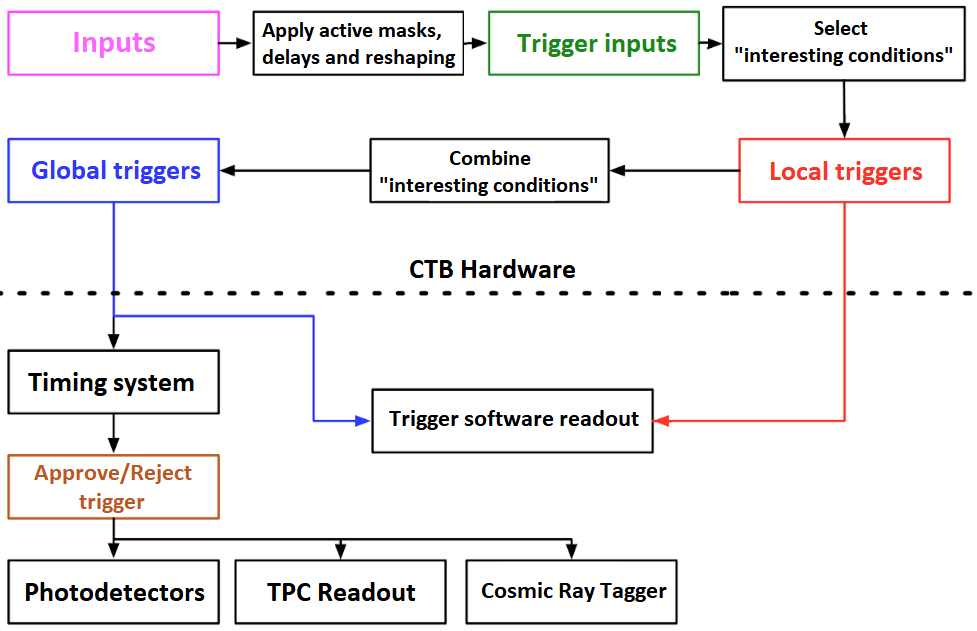

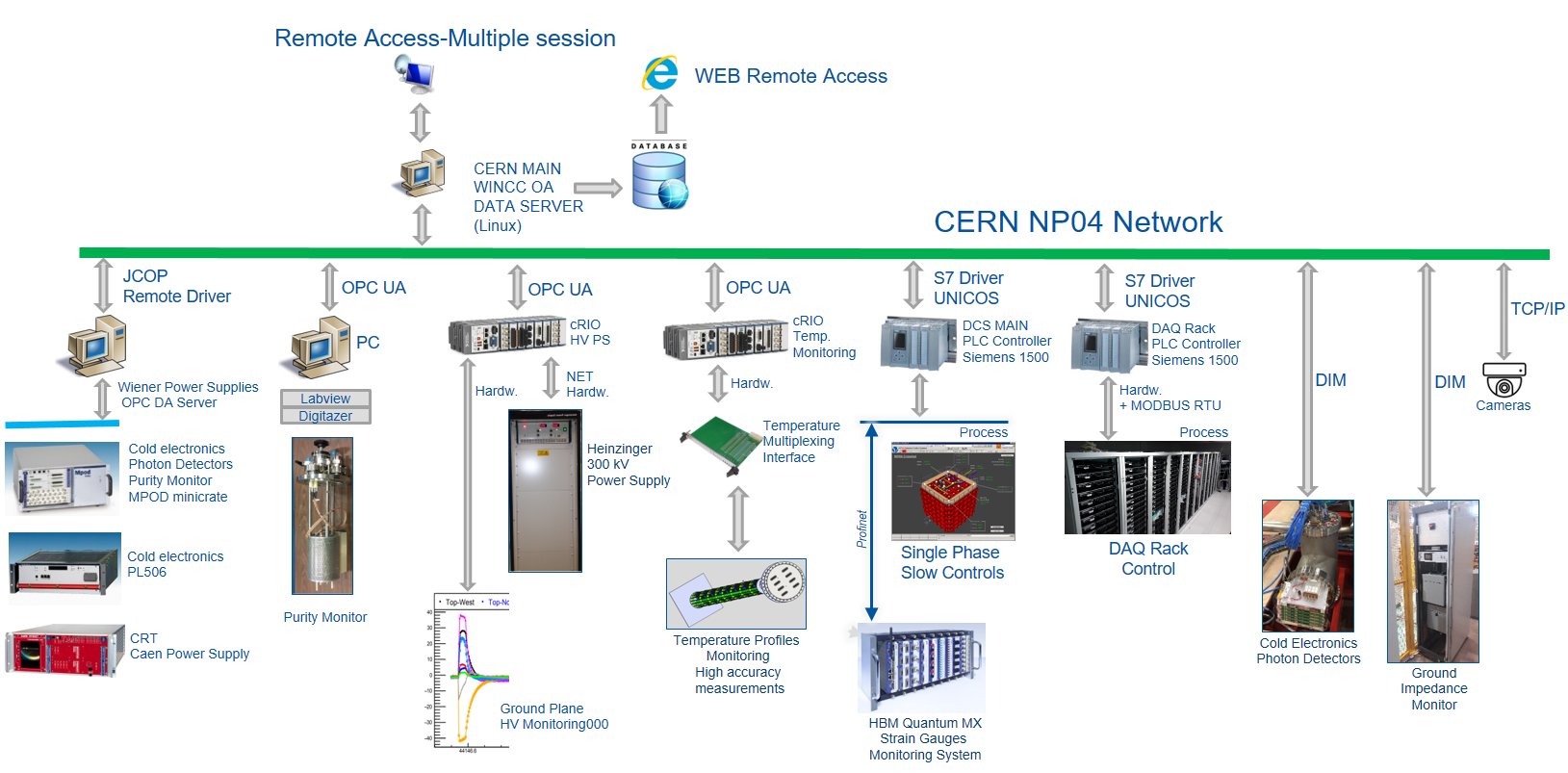

1.4 Data Acquisition and Detector Control

The Data Acquisition (DAQ) system, a central element of ProtoDUNE-SP, interfaces with the detector’s readout electronics, with external devices used for triggering (e.g., beam instrumentation), with the Detector Control System (DCS), and with the offline computing. The DCS (known historically as “slow control”) is in charge of the monitoring and control of the detector and includes hardware and software elements that give information and access to the detector subcomponents. The DAQ and DCS are described in Section 6 of this paper.

2 The Neutrino Platform at CERN

Following the recommendation issued by the 2013 European Strategy for Particle Physics [4] the Neutrino Platform was established at CERN to foster the European contribution to the next generation of long-baseline neutrino experiments. Use of this new and versatile facility is regulated through Memorandum of Understanding (MOU) agreements, making it easy to welcome contributions from new collaborators and new projects within the facility. Since its establishment, several new projects have been included and extensions of existing ones have been approved.

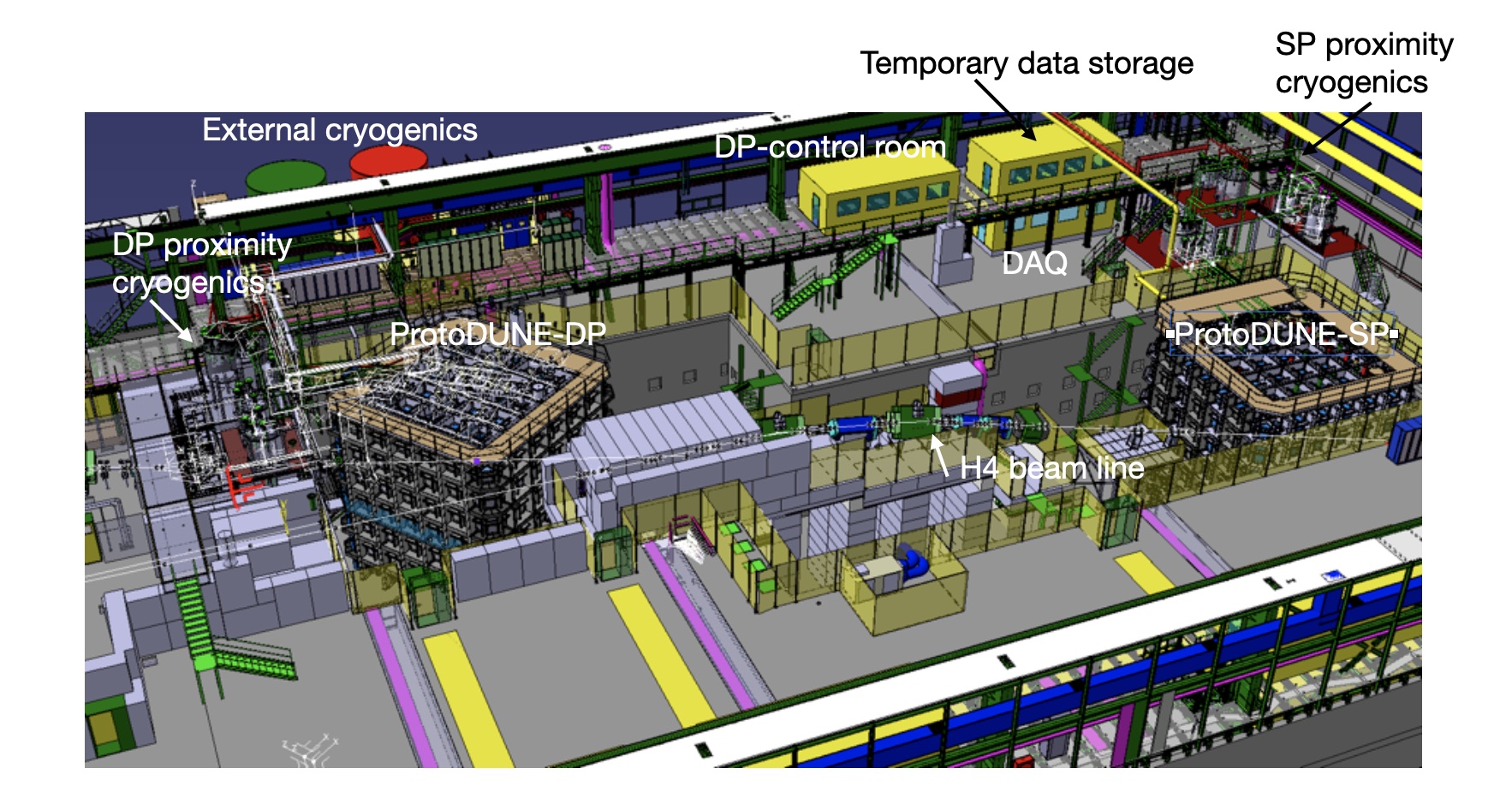

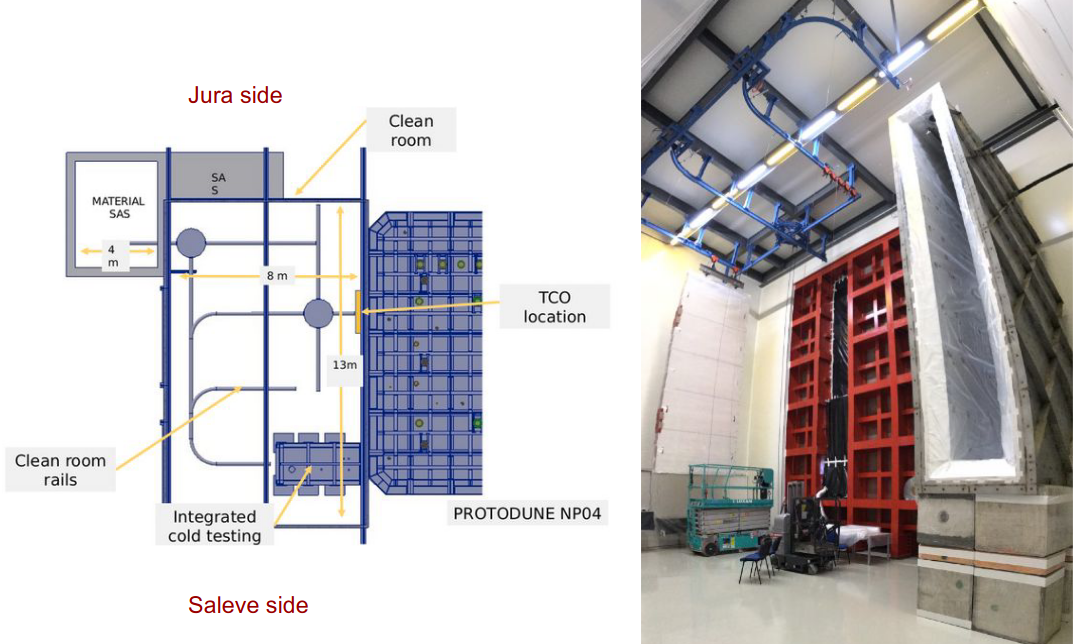

The CERN NP is located at the Prévessin site, in an extension of Building 887 (EHN1) built explicitly for housing the two large-scale ProtoDUNEs, ProtoDUNE-SP and the dual-phase ProtoDUNE-DP, where they can be exposed to charged particle beams. The Neutrino Platform provides the infrastructure needed to safely construct, install, and operate the two large LArTPCs, e.g., storage space for large components, dedicated overhead cranes for the handling of heavy equipment by trained personnel, logistics and transport services coherently integrated with the CERN global transport service, and mobile elevating working platform devices.

Each of the ProtoDUNEs is installed inside a cryostat located in an open trench in EHN1 12 m deep. The building also houses prefabricated experimental control rooms and a cryogenics control room, as well as rooms dedicated to data acquisition and computing/storage facilities. Figure 2 shows a layout of the experimental area.

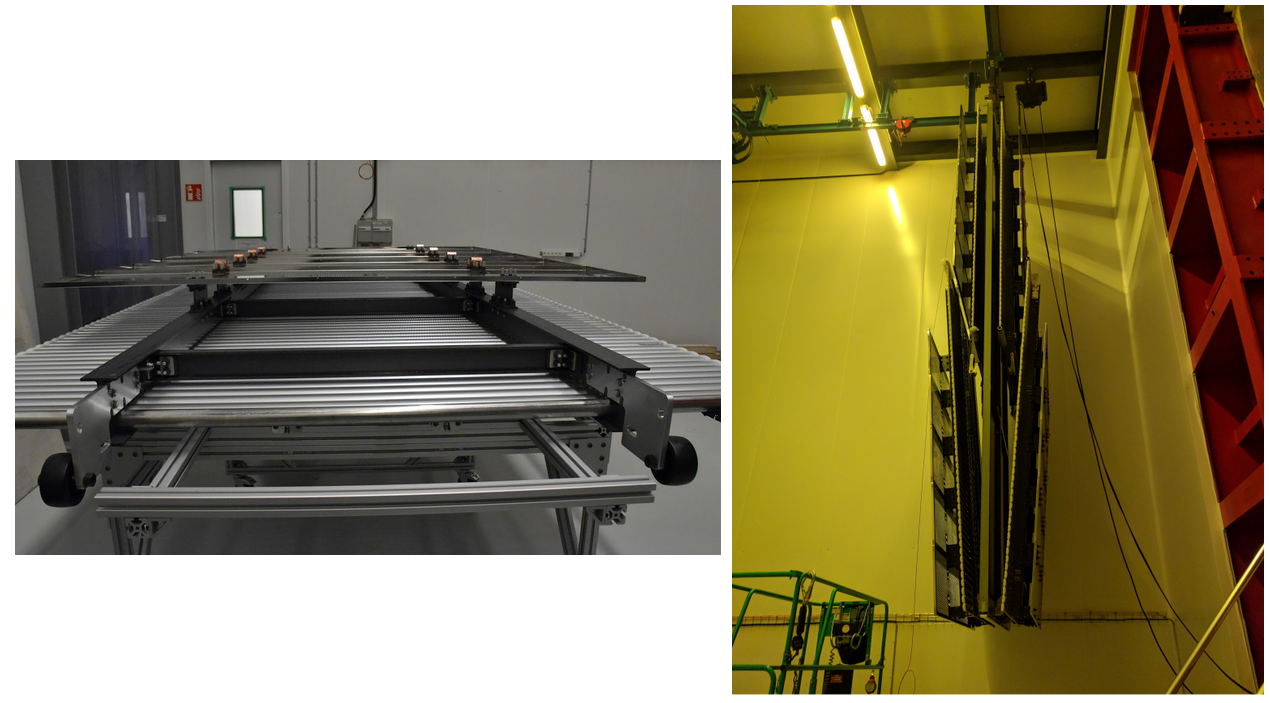

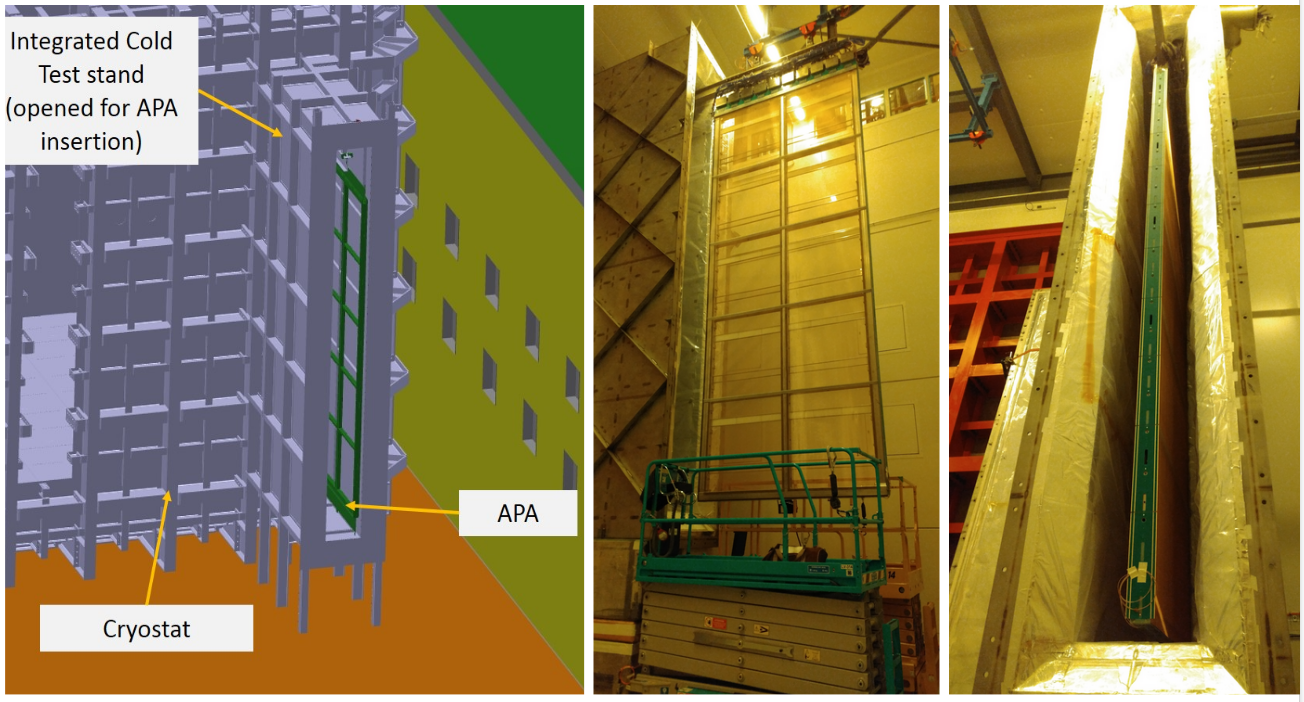

A specialised piece of infrastructure is the so-called NP-04 cold box and its cryogenics system. Built for characterisation of the APAs at low temperature prior to their installation into the ProtoDUNE-SP cryostat, it is a tall, thin cryostat filled with cold nitrogen gas.

Two newly designed Very Low Energy (VLE) beamlines, H2 and H4, serve the two detectors [5]. Protons from the Super Proton Synchrotron (SPS) strike the T2 target about 600 m upstream of the detectors, generating secondary particles that collide with secondary targets that in turn produce particles of momenta in the region of 0.3-7 GeV/c [6]. The H4 beam is directed to ProtoDUNE-SP and the H2 beam to ProtoDUNE-DP. The beam lines and the beam instrumentation were commissioned in the summer of 2018 and the H4 beam extension was operated until the beginning of CERN’s Long Shutdown 2 in November 2018 [7].

Two large clean rooms next to each cryostat were used to construct, assemble, and manipulate the delicate detector components using procedures developed to ensure the required level of cleanliness of the atmosphere and equipment.

Each cryostat has its own cryogenics system that comprises (1) the inner cryogenics and (2) the proximity cryogenics. These systems together provide and control the flow of the liquid and gases, and monitor and act to preserve both the thermodynamic conditions inside the cryostat and the liquid argon purity. The cryogenics system also has equipment external to the building that is used by both cryostats. This external system stores and delivers the liquid argon for the cryogenics operations as described in Section 3.3.

A very tight schedule and rigorous safety requirements led to very challenging installation and commissioning periods for the ProtoDUNE-SP cryostat and detector. A dedicated team and a set of tools and protocols were established to ensure that safety requirements were met and to coordinate parallel activities.

During the installation phase, mechanical and structural hazards posed the most significant safety concerns, and during the operational phase, cryogenics and radiation hazards were the prominent concerns. The facility was fully equipped to ensure safety of the personnel and the equipment at all times. Systems and procedures were put in place to mitigate risks associated with these hazards, including personnel training, specific risk analyses for non-standard activities, systems for oxygen deficiency hazard (ODH) monitoring and for fire detection, both linked to the hall ventilation and to the evacuation sirens and the CERN Fire Brigade. During beam operations, protocols were put in place to avoid accidental exposure to beam, e.g., access to the beam area and the trenches was controlled and interlocked with the beam. The radiation level in the hall was monitored with a series of strategically positioned radiation monitors integrated into the beam interlock system.

The CERN NP has approved Phase II of ProtoDUNE-SP, the most significant of its new projects and extensions. Starting in 2022, once the DUNE-SP detector component designs have implemented all the improvements of the past few years and are final, the components will be installed in the same cryostat used for Phase I and tested.

3 Cryostat and Cryogenics

The cryostat consists of a free-standing warm steel outer structure, layers of insulation, and a cold inner membrane. Its design is based on the technology used for liquefied natural gas (LNG) storage and transport. The outer structure, which provides the mechanical support for the membrane and its insulation, consists of vertical beams that alternate with a web of metal frames. It is designed to withstand the hydrostatic pressure of the liquid argon and the pressure of the gas volumes, and to satisfy the external constraints.

3.1 Cryostat Assembly: Design, Installation and Validation

The LBNF/DUNE far detector membrane cryostats are required to be constructed of modular components that can be transported to the underground caverns at SURF via a 1.4 m 3.8 m cross section shaft for assembly in situ. The ProtoDUNE-SP cryostat, which is intended to validate the far detector design, was constructed of modular components of the same design and size. The maximum dimensions and weight of the cryostat components were optimized to work in both the SURF and CERN locations.

The ProtoDUNE-SP cryostat design builds on similar technologies used for liquefied natural gas (LNG) storage and transport tanker ships. A 1.2 mm thick corrugated stainless steel membrane forms a sealed container for the liquid argon, with surrounding layers of thermal insulation and vapor barriers. Outside these layers, a steel frame forms the outer (warm) vessel. The roof of the cryostat supports most of the components and equipment within the cryostat, e.g., the time projection chamber (TPC) and photon detection system (PDS) components, electronics, and sensors.

The ProtoDUNE-SP cryostat holds approximately 550 m3 of LAr, assuming an ullage of 5%, at a temperature between 86.9 K and 88.2 K with an absolute pressure inside the volume in the range 970–1100 mbar111the quoted pressure are referring to the pressure in the ullage, if not specified otherwise. . The maximum design gauge pressure is 350 mbarg. The average heat leak is tightly controlled and kept around 8 W/m2 to avoid rapid boiling of the LAr and therefore limit the consumption of liquid nitrogen (LN2) which is used during normal operations to recondense the boiled off argon via a heat exchanger.

The ProtoDUNE-SP cryostat and associated cryogenics have successfully validated the designs for use in large-scale LArTPC experiments and in particular for the DUNE far detector.

3.1.1 Cryostat Outer Structure

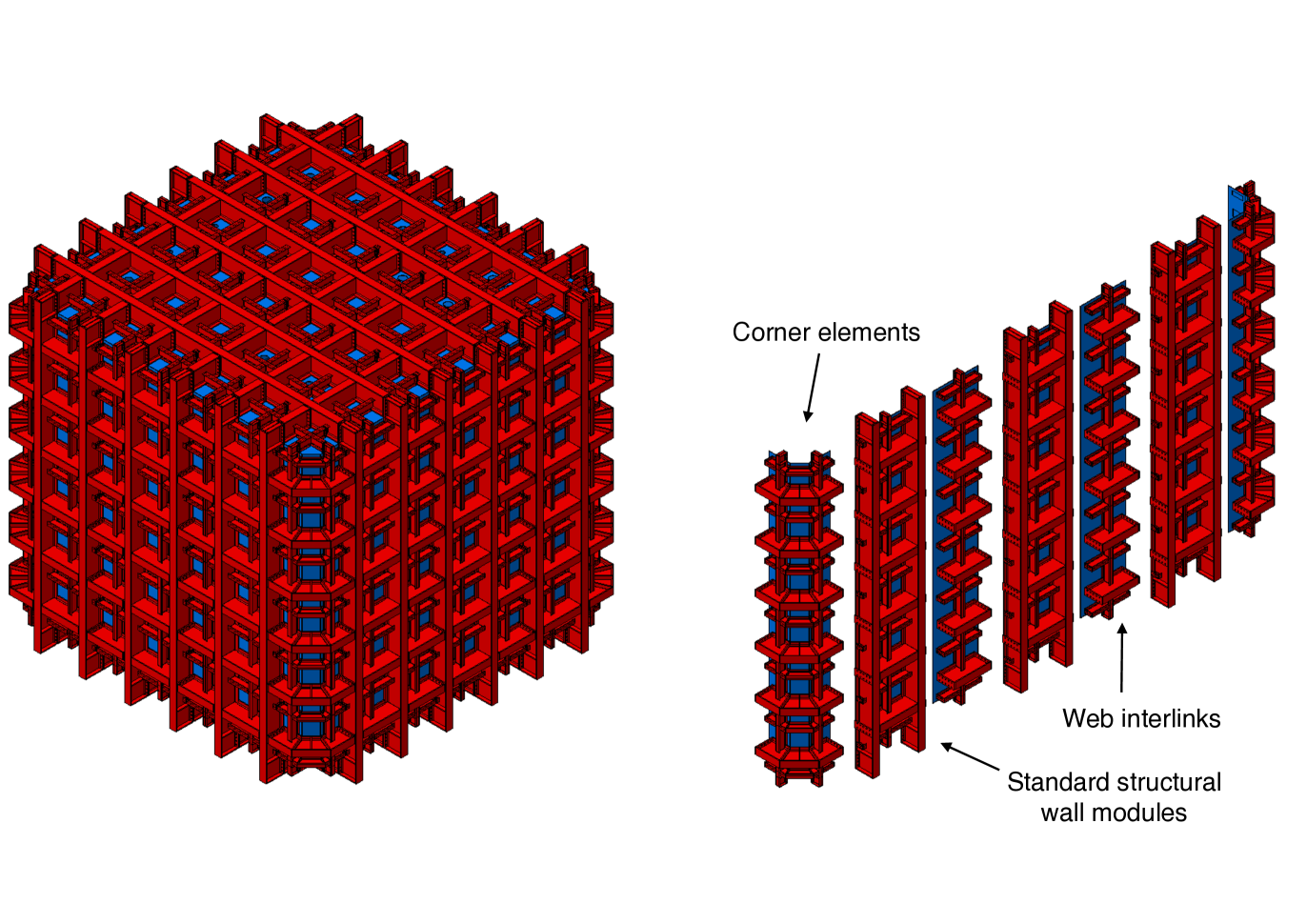

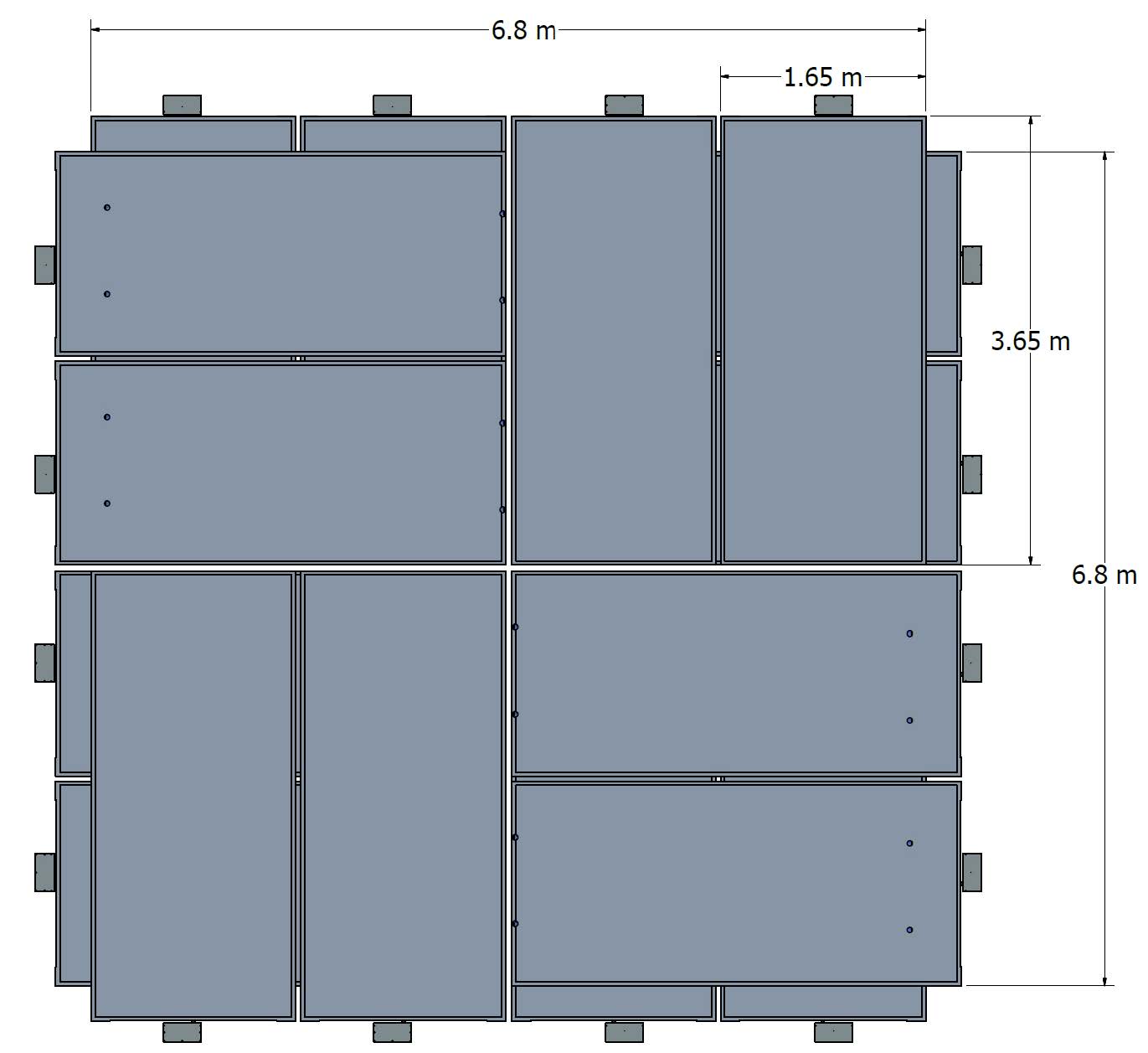

The cryostat is a free-standing, electrically isolated structure assembled in the EHN1 hall at the CERN Prévessin site. The room-temperature outer structure provides the structural integrity of the entire setup, being capable of withstanding the hydrostatic pressure of the LAr, the pressure of the argon vapor, the detector weight, and gravitational and seismic forces. The overall nominal outer dimensions are: (WLH) and the nominal inner cryostat dimensions are: .

These dimensions are dictated by several constraints: the required active volumes of LAr and ullage, the layout of the penetrations, installation needs, distances from the active volume to the cryostat inner walls, and insulation thicknesses.

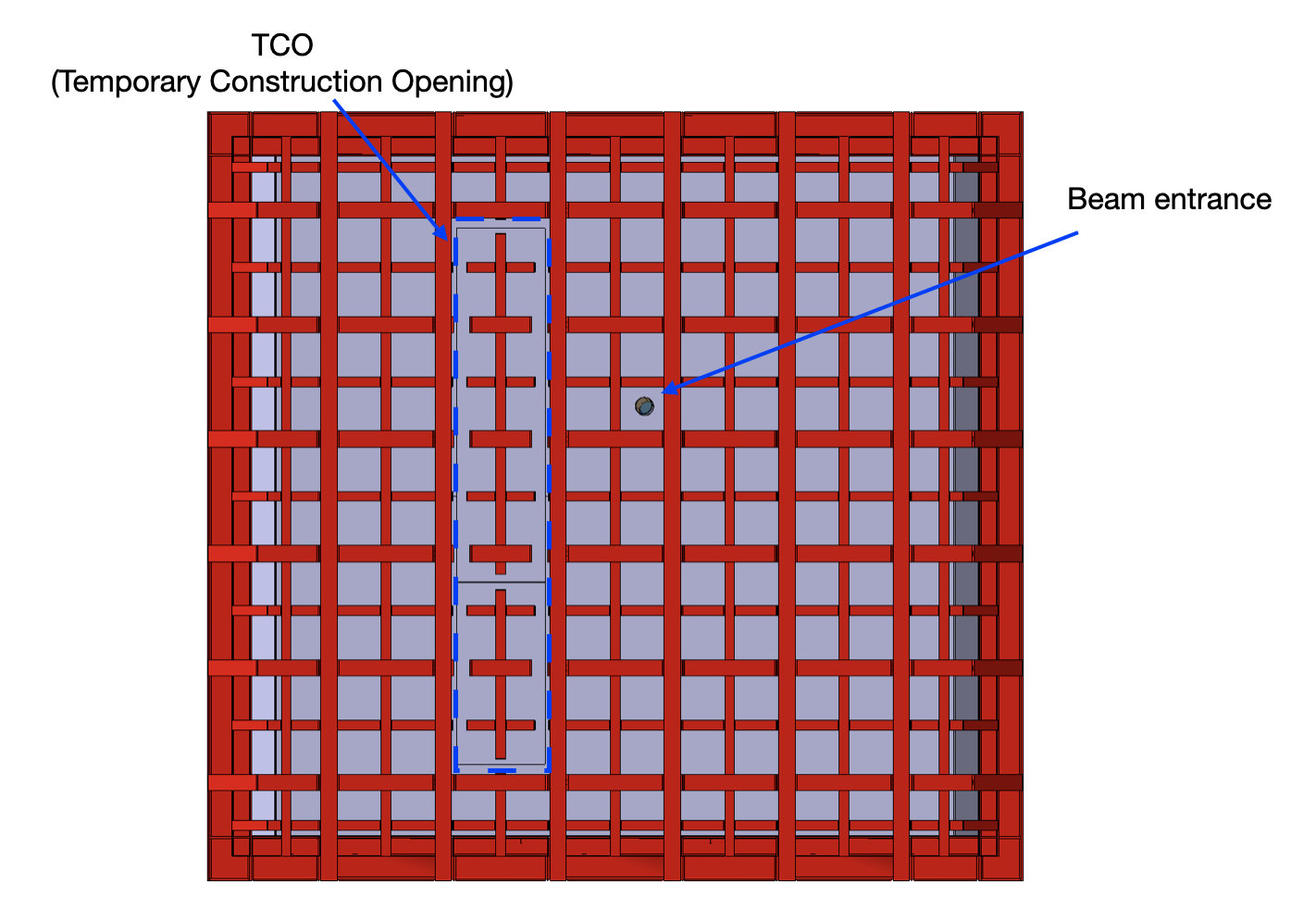

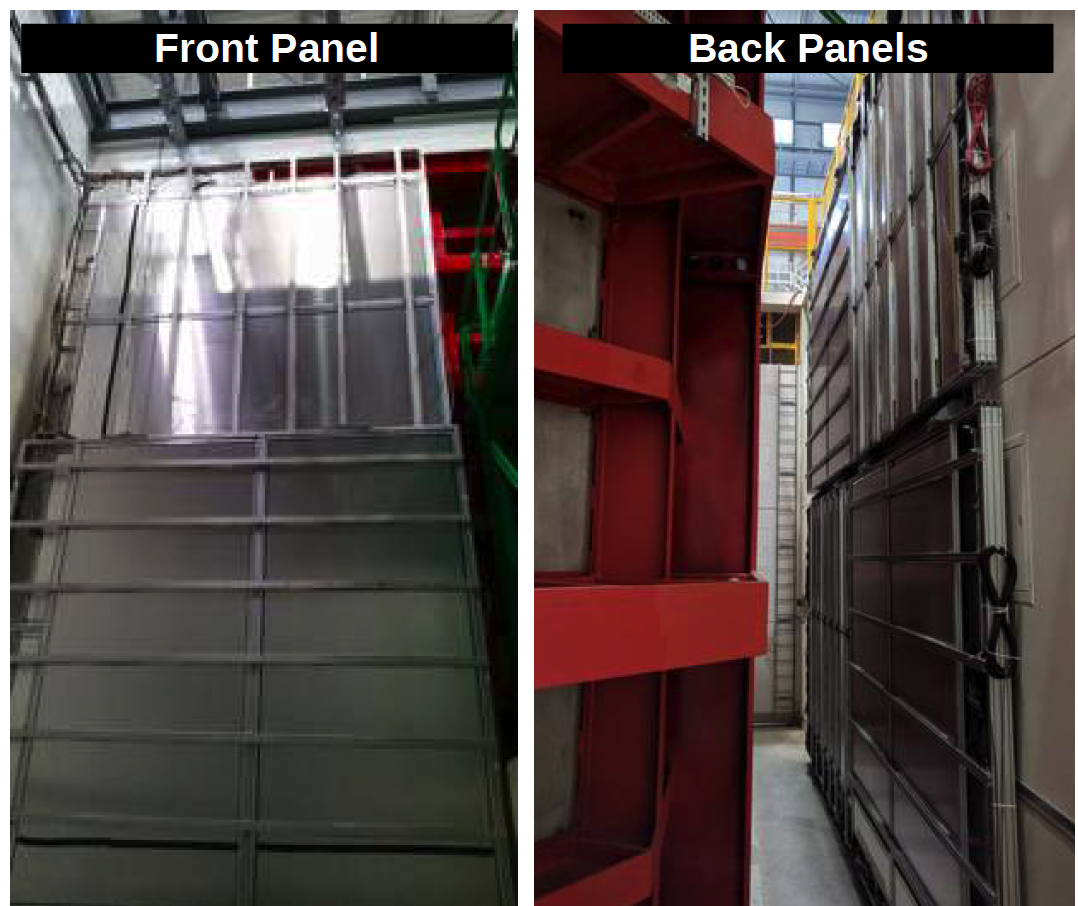

The outer structure consists of an assembly of prefabricated S460ML [8] steel modules of three configurations: standard structural modules used to construct the walls and floor, corner elements and a web of metallic frames to interconnect the modules. The complete structure and the modules used to assemble each face of the cryostat are shown in Figure 3. The modules are assembled using standard hot-rolled profiles welded together with bolted connections.

Three of the four cryostat outer walls are identical. The front wall, through which the beam enters, has a beam window (Section 4.1.3) and a separate wall section that is sealed in place over a Temporary Construction Opening (TCO), a 7.3 m high and 1.2 m wide entrance used for installing detector components.

3.1.2 Insulation and Cold Membrane

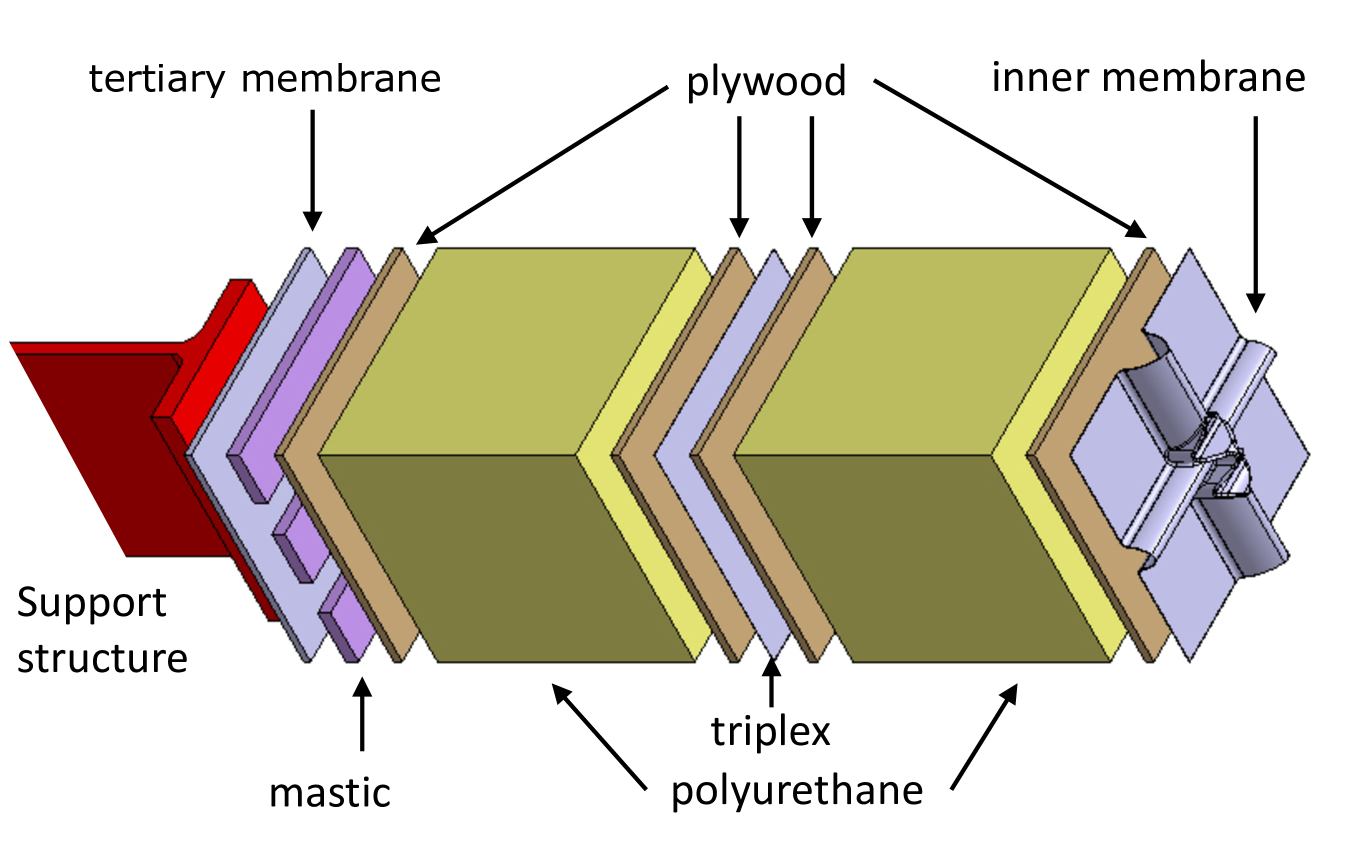

The inner vessel design, installed inside the warm support structure, is based on the LNG transport membrane technology developed by the firm GTT (Gaztransport & Technigaz) [9]. The overall thickness of the inner vessel is 800 mm. The design fulfills the requirement that thermal fluxes not exceed 5-6 W/m2 222This value also accounts for the aging properties of the insulation material (20 years of operation).. The outermost layer of the inner vessel is a 10 mm thick stainless steel membrane [10] (the tertiary membrane) that provides an effective gas enclosure and allows for control of the nitrogen atmosphere inside the insulation volume, which prevents condensation in the insulation layer.

Moving inward, just inside that membrane is the insulation layer that consists of two 390 mm thick layers of a foam specially developed for this purpose, supported by plywood plates of 9 mm and 12 mm thickness. The foam material is expanded polyurethane of density 90 kg/m3. The outer insulation layer is attached to the tertiary membrane by a set of rods and special mastic. Between the two insulation layers is a secondary LAr containment layer made of GTT-proprietary Triplex, a composite material consisting of a thin sheet of aluminum laminated on both sides by a layer of glass cloth and resin. In contact with the innermost side of the foam insulation is the 304L stainless steel 1.2 mm thick primary membrane that holds the LAr. The primary membrane can expand or shrink in two dimensions as a function of the temperature, thanks to a special corrugation configuration that allows it to respond like a bi-dimensional spring. A cross sectional view of the insulation and membrane layers is shown in Figure 4(a). Figure 4(b) shows a view of the interior of the ProtoDUNE-SP cryostat before the insertion of the detector modules and the closure of the TCO. The corrugations of the primary membrane are visible.

Once all the large detector components have been installed inside the cryostat, the TCO is closed. The sealing is done in two steps since the entire length of the TCO is divided along the horizontal axis, into two parts. First the top part is bolted and sealed with the standard outer structure section. The layers of insulation are installed from inside the cryostat, following the standard sequence presented above. Once the primary membrane of the top part of the TCO is also installed, all the material needed for the bottom part is brought inside the cryostat and the sequence done for the top part is repeated. Since the sealing of the TCO involves welding activities inside the inner volume, a temporary “dirty room” was built to protect the detector components during those operations.

Figure 5 shows the TCO. The circular opening for the beam entrance is also visible.

3.1.3 Signal and Service Penetrations

The penetrations into the cryostat are installed on the roof of the warm structure, with a couple of exceptions. To keep the high level of purity required, LAr is extracted from a point as low as possible in the cryostat and pushed by cryo-pumps to the external filtering system through the liquid recirculation circuit (see Section 3.3). A special penetration is thus required low on one of the cryostat’s side walls to connect to the LAr pumps. This penetration has a dedicated system of safety valves and involves local modifications to the insulation panels and the primary membrane.

Since ProtoDUNE-SP was designed for exposure to a charged particle beam from CERN’s SPS, a second modification to the cryostat was made to accommodate a beam window. The window minimises energy loss and scattering, which would be much higher if the beam were to pass through all the cryostat layers (see Section 4.1.3). The installation of the beam entrance window does not require any particular modification of the warm support structure. The tertiary membrane has been perforated with a hole where the beam entrance window is installed. The beam entrance window is composed of 175 -thick Mylar foil and a gate valve that opens when the beam is present and closes for safety reasons when the beam is off. The insulation between the secondary and the tertiary membrane is removed in the region around the beam window and the foam between the secondary and the primary membrane is replaced with a lower density foam (9 kg/m3). Finally the plywood supporting the primary membrane in the vicinity of the beam window penetration is replaced with a Nomex honeycomb plate sandwiched between thin G10 layers. Nomex is a polymer material with high thermal resistance and Nomex sandwiches are well known for their structural resistance . Thermal and stress analyses to validate the design were conducted in collaboration with GTT. The total amount of material, including the (unaffected) primary membrane, given a 0.3 mm G10 thickness and a 0.3-mm-thick steel beam window, is equivalent to 10% of a radiation length.

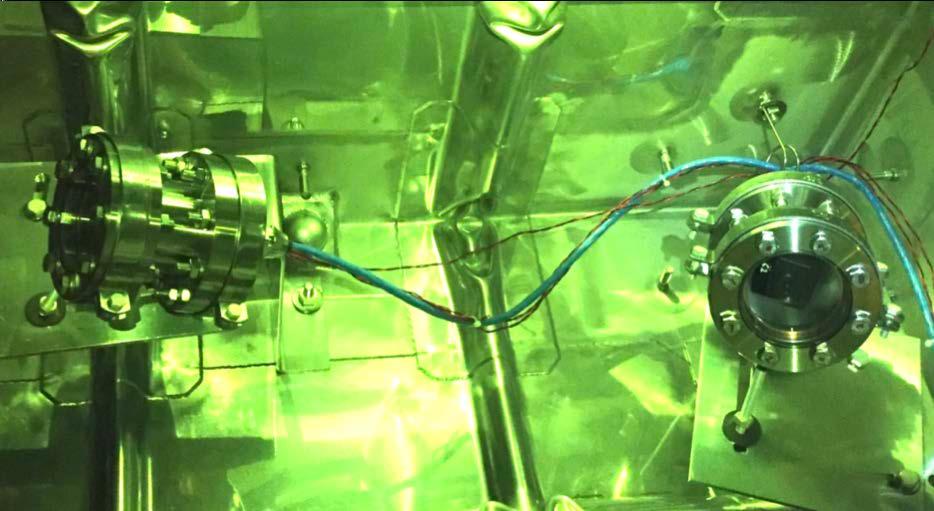

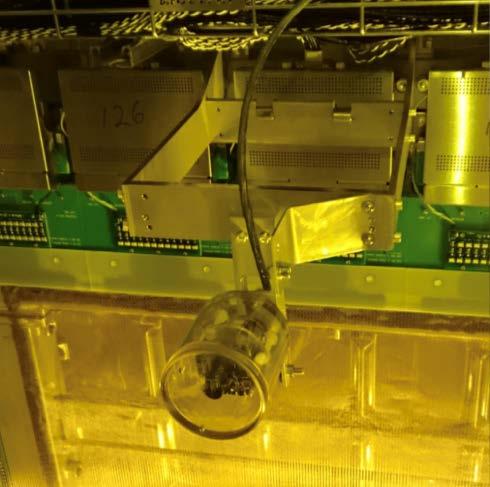

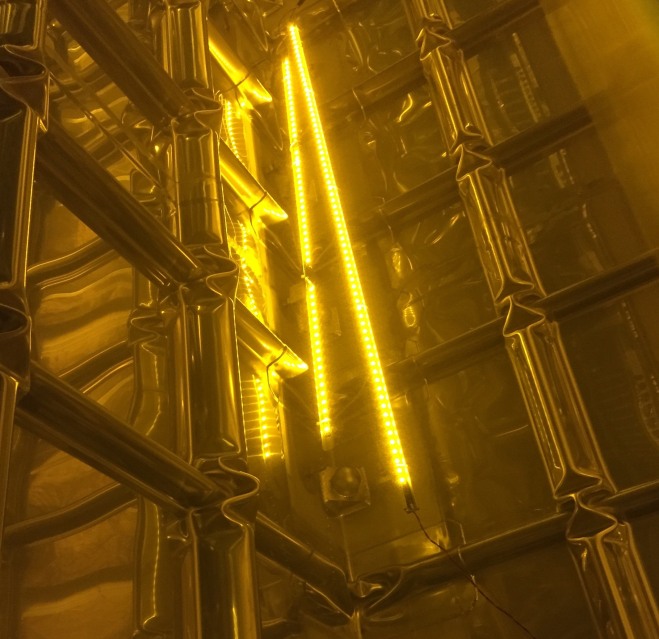

The other penetrations, all on the cryostat roof, are grouped by position, diameter, and function. They provide feedthroughs for the TPC detector power and signals, support for the argon instrumentation devices, and feedthroughs for the instrumentation signals. Of the 55 penetrations, 43 go through to the liquid of which seven are dedicated to the cryogenics system, nine to the detector support system, six to detector charge and light readout, and one to the cathode HV feedthrough. One is for the beamplug services, one for the diffuser fibre, 11 for the monitoring system (cameras, temperature and pressure sensors, purity monitors). There are also two manholes and five spares. The remaining 12 penetrations are limited to the insulation volume and are dedicated to either input/output of nitrogen gas or temperature and pressure sensors.

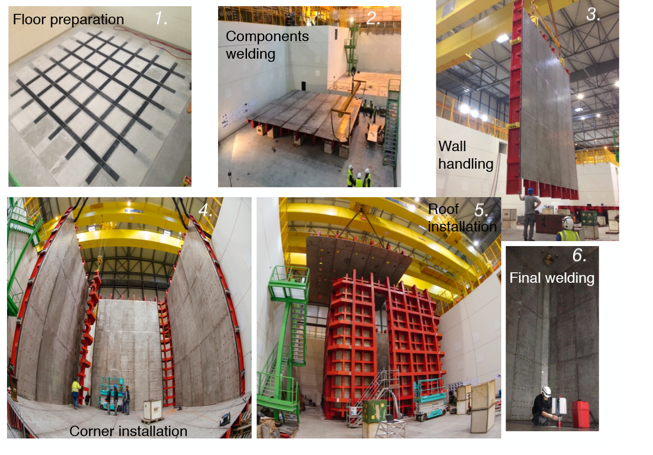

3.1.4 Cryostat Assembly Procedure

Figure 6 shows steps in the assembly sequence of the outer support structure. Installation starts with a planarity survey of the floor and the positioning of the elastomer pads and G10 strips (for seismic protection and electrical isolation) on which the cryostat will be placed. Three pre-assembled large wall pieces are positioned horizontally on temporary concrete supports, then three web interlink modules are positioned between them and connected together as shown in Figure 3 (right). The stainless-steel plates of the outermost (tertiary) membrane are then welded together and a helium leak test is performed to qualify the welds (see Section 3.2.1). To ensure the planarity of each completed wall, a detailed survey is carried out before it is lifted and installed in its final position on the elastometer pads. Wherever needed, temporary stabilisers are added to the experimental pit concrete walls to ensure safety during this process. Once the four walls are in place, the four pre-assembled cryostat corners are installed and the stabilisers are removed. Finally, the roof modules are assembled and the roof is installed. A final helium check of the SS plate welding is performed, and a global three-dimensional scan is done to verify the internal dimensions.

Once the outer structure and the tertiary membrane are installed, the pre-cut inner layer sections that come pre-assembled with mastic and fasteners are installed. After each layer is completed, all voids are filled to stop any circulation paths. At the end, helium leak tests are performed once again (see Section 3.2.1). The installation proceeds by layers (see Figure 4(a)) with the inner membrane installed last. Installation of the ProtoDUNE-SP warm structure took about 12 weeks.

3.2 Cryostat Structure Validation and Testing Campaigns

Validation and certification of the cryostat structure has two aspects. The first, leak checking, is performed at various stages of the cryostat construction. A description of these tests is given in Section 3.2.1. The second concerns the mechanical behaviour of the cryostat in terms of compliance with engineering safety standards and regulations. This validation is also performed multiple times throughout the course of construction, and also includes a test campaign done during and after filling with LAr. The structural and mechanical performance validation is described in Section 3.2.2.

3.2.1 Cryostat Tightness Verification

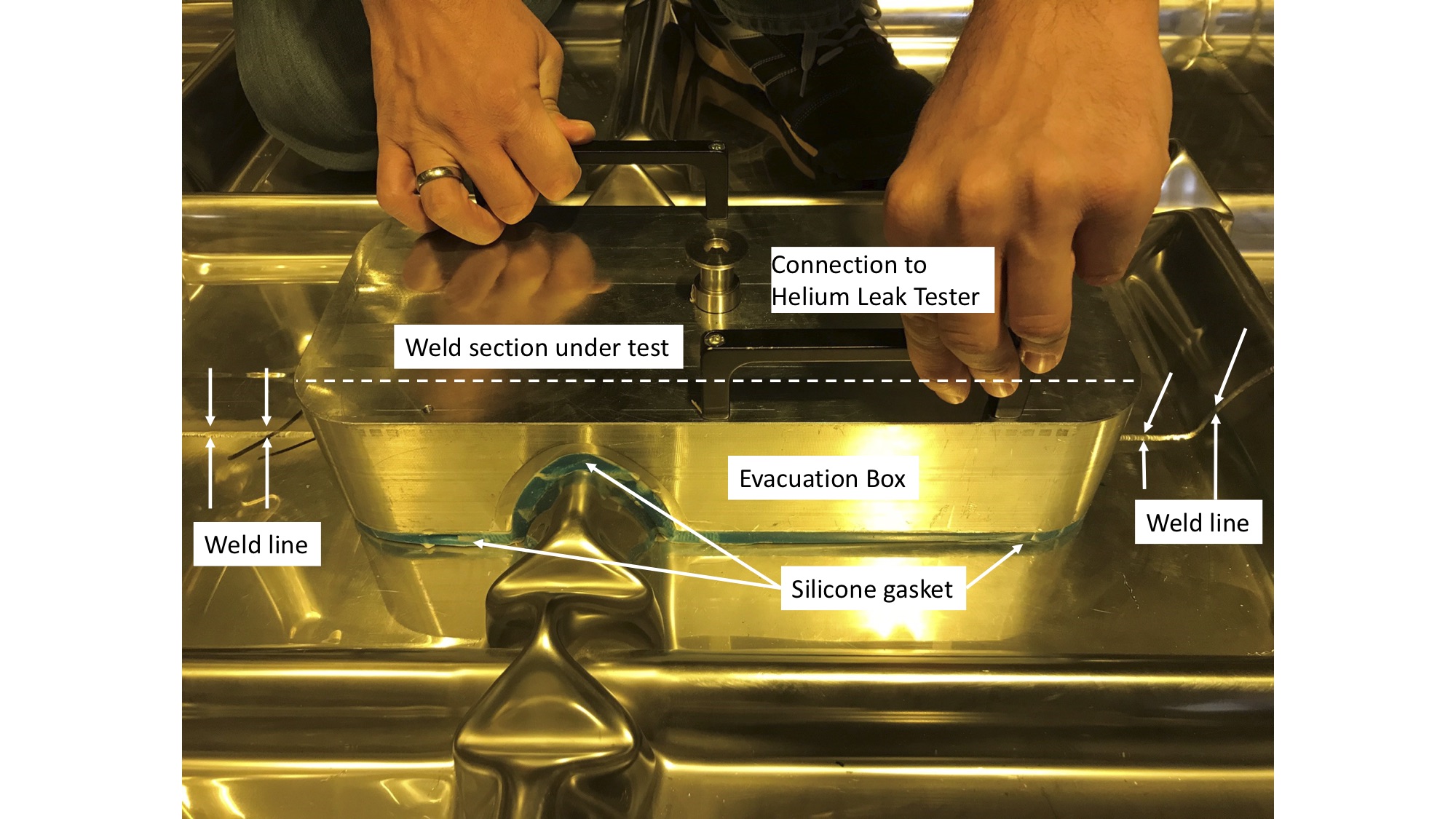

Leak testing is performed on the external warm structure, the inner membrane, and all the penetrations. The tests are generally done using helium and a leak detector in sniffing mode. A deviation from the environmental background ( mbar l/s) is considered a possible leak.

Warm Structure

The walls of the cryostat outer structure (see Section 3.1.1), despite their separation from the LAr volume, are required to be leak-tight for two main reasons: they are the last barrier between the LAr volume and the external world; and any leaks on the outer surface would be sources of localised heat and humidity injection. The latter would produce water that would freeze inside the insulation volume, weakening it and making it less effective. The checks were performed during the assembly of ProtoDUNE-SP and no leaks were found.

Inner membrane

The cryostat inner membrane (see Section 3.1.2) was tested twice for leaks. The first test, upon completion of the membrane installation, was the official qualification for leak-tightness by the vendor, and was performed on all welding seams. In this test, the insulation volume, normally flushed with N2 gas, undergoes a few cycles of evacuation (down to roughly 550 mbar), then is filled with helium to match the external pressure. This allows a uniform fill of the insulation with helium. Two test holes in the lower inner membrane are intentionally not welded at this stage, but simply closed with mastic to allow occasional checks for the continued presence of helium in the volume under test. The few small leaks found were swiftly repaired. These test conditions also allowed for continuous monitoring of the insulation space internal pressure stability (Primary Barrier Global Test).

The second leak test involved pulling vacuum around localised sections of welding lines and testing them one by one. The test measures the leak rate from the helium-rich atmosphere, through the welds of the primary membrane, to a local volume evacuated by means of a vacuum box (Figure 7). The vacuum boxes come in a variety of shapes to fit corrugations, corners, and flat welded regions. Overall, about 80% of the total length of welding lines on the inner membrane was tested and no leaks were found. It is worth mentioning that a similar double-test procedure was performed on the ProtoDUNE-DP cryostat’s inner membrane and yielded the same result. This gives confidence that the helium leak-check performed by the vendor can be fully trusted when it comes time to verify the cryostat inner membranes for the far detector, and that performing the second test will be unnecessary. Retesting single welded lines on a DUNE-scale cryostat would require months.

Roof penetrations

The leak-tightness of all feedthrough flanges was verified. This was done to avoid the potential formation of argon gas (GAr) pockets on the cryostat roof, a working area during operation, and also to prevent air leaks that could pollute the LAr volume. Each penetration was tested after closing the corresponding flanged connections.

The test procedure changed slightly depending on the stage of the detector preparation: the helium was injected into the penetration under test either from the inside (cryostat volume still accessible) or using the argon gas exhaust lines present in every penetration (detector installation completed).

All flanges except one were certified to be leak-tight; the chimney of one temperature profiler (see Section 4.5.2) was found to be faulty. None of the actions taken fixed the leak entirely, therefore an enclosure was constructed and installed around the leaky flange, defining a buffer volume in which argon gas circulated continuously.

3.2.2 Cryostat Mechanical Performance and Test Campaign

The cryostat inner and outer structures must satisfy European regulations and standards, as the ProtoDUNE-SP cryostat was installed and operated in Europe. In addition, since the design and the construction methods and technologies are prototypes for the larger DUNE cryostats, compliance with U.S. standards and regulations is also required.

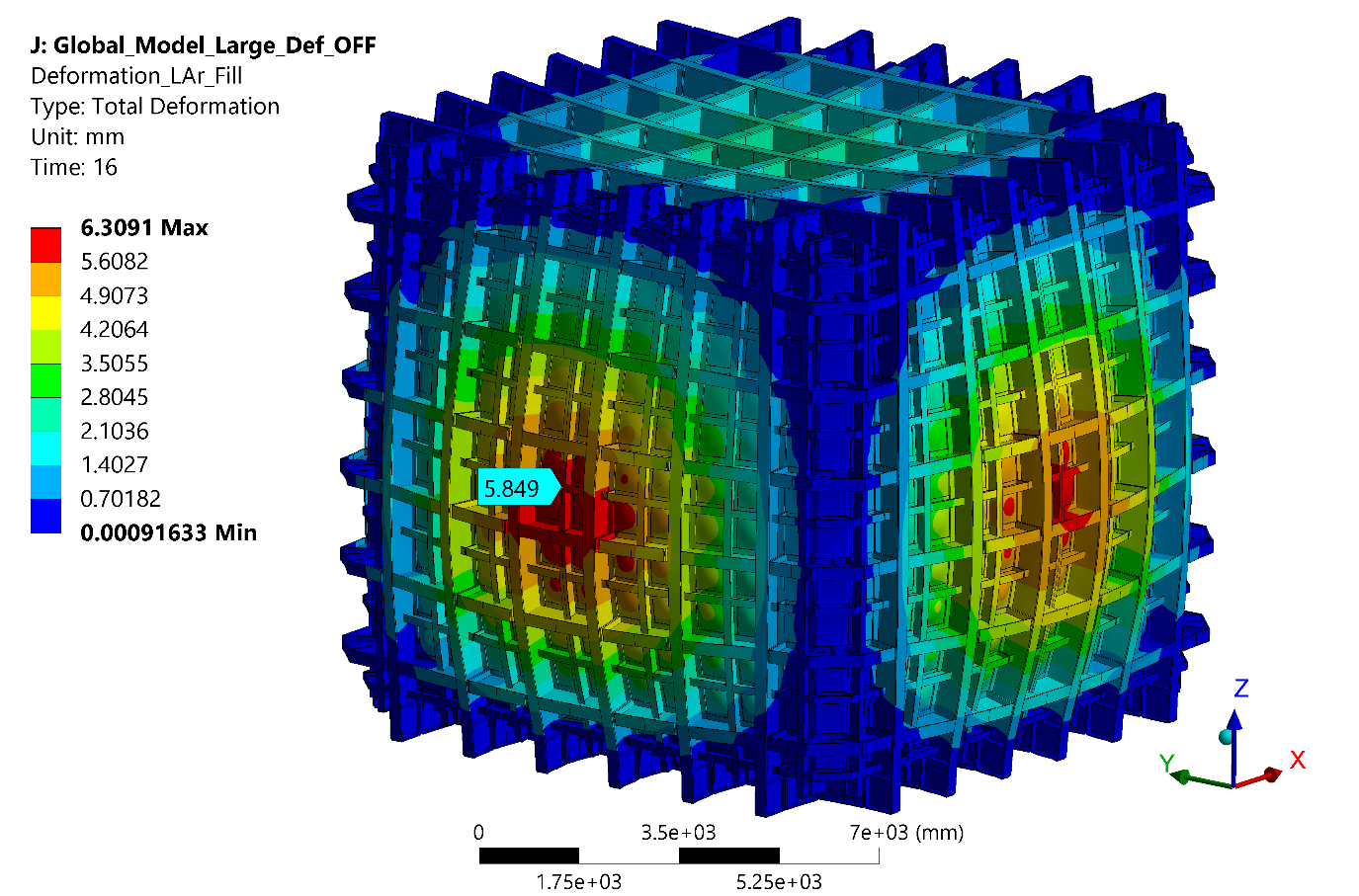

Rigorous quality assurance and control procedures were carried out on all materials and techniques used for the construction of the ProtoDUNE-SP cryostat. The cryostat outer structure is instrumented with strain gauges and displacement sensors for making the required measurements. To fully validate the mechanical performance of the cryostat, a careful stress analysis of each structural component was done, together with pressure tests before and after filling with LAr.

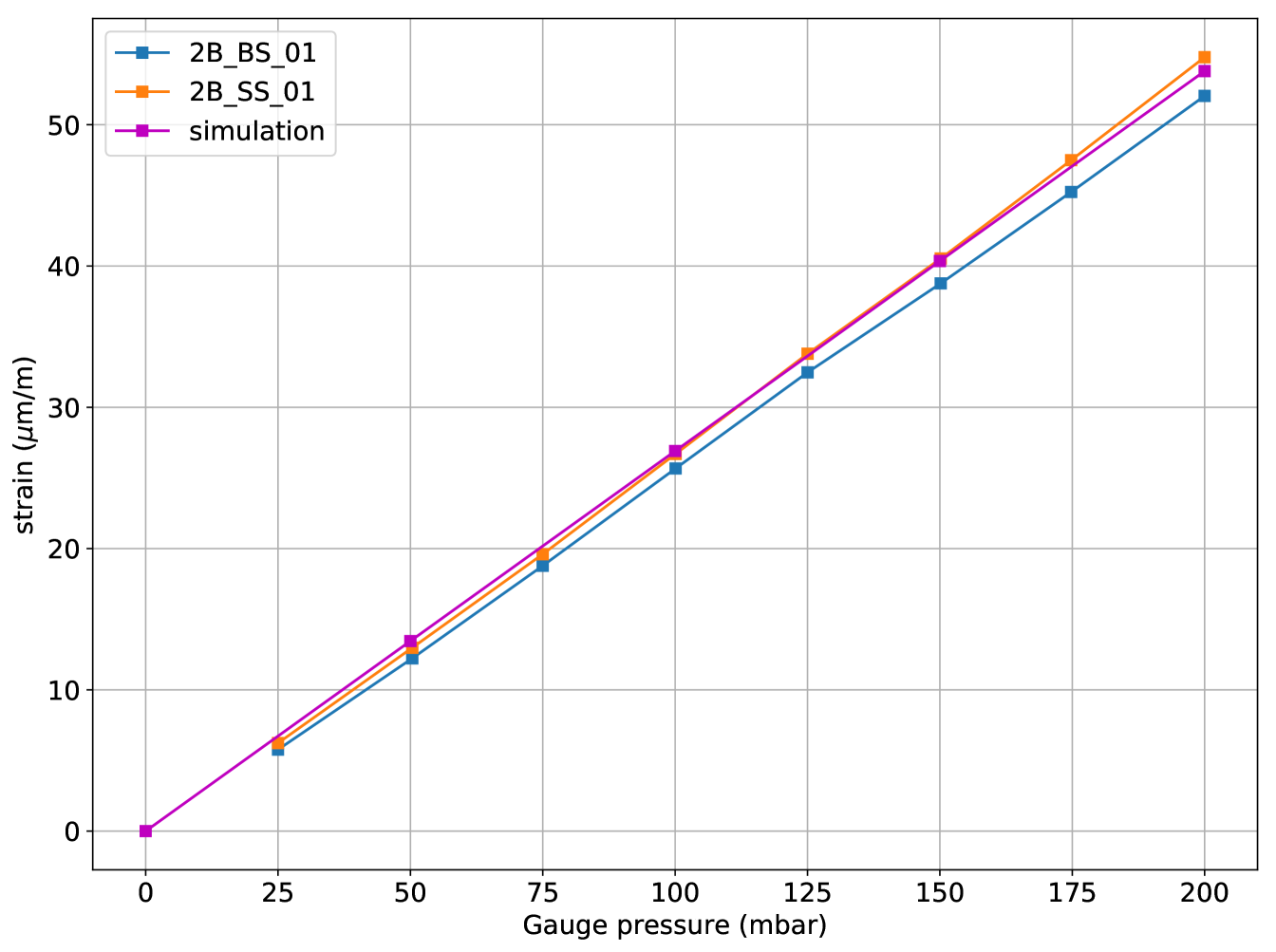

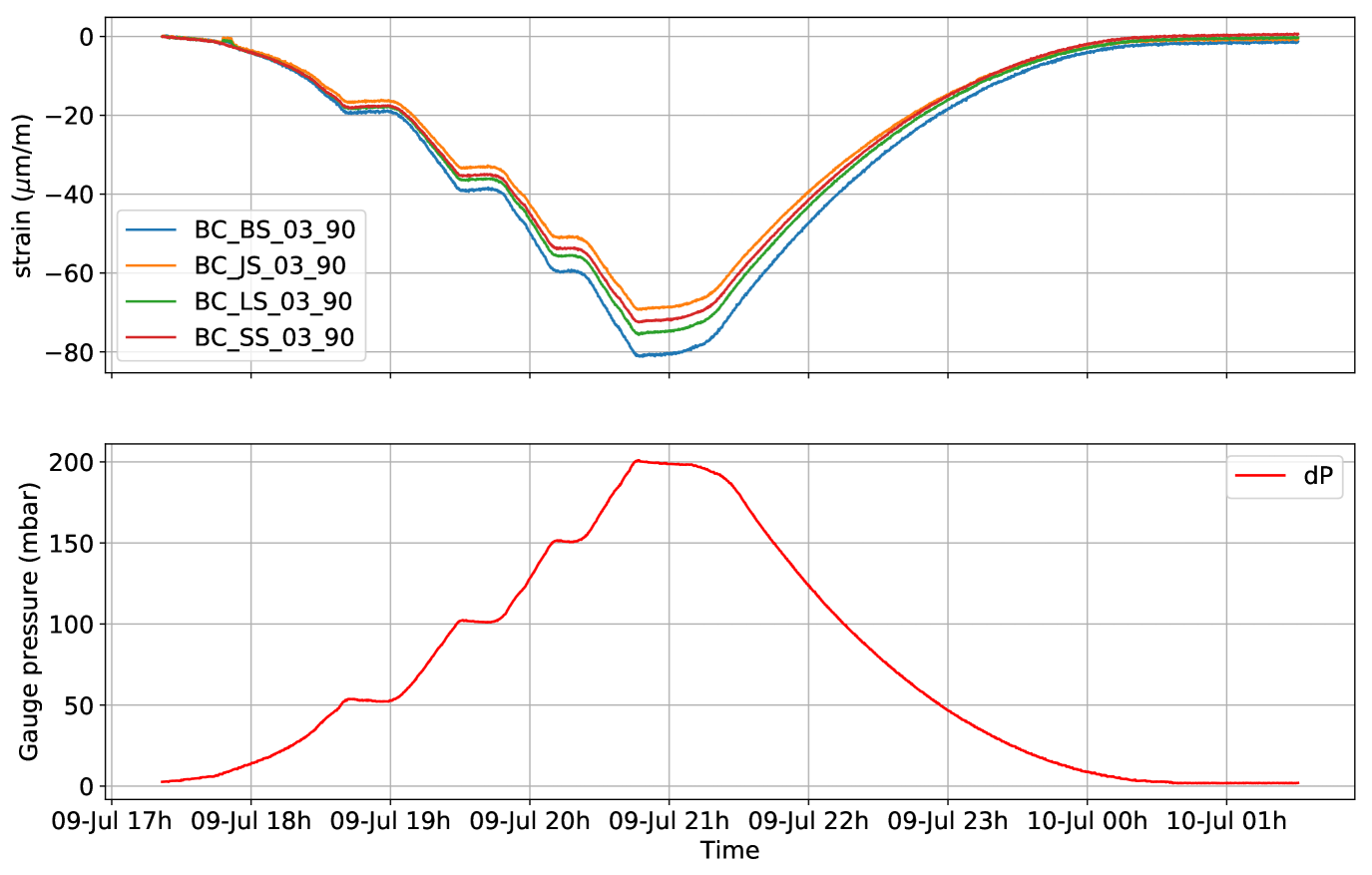

Two Finite Element Analysis (FEA) models were developed to evaluate the cryostat design against the required codes and regulations. Predictions from the models were compared to the experimental data collected during the commissioning phase and operation. A relatively simple beam model includes simulations only of the cryostat outer structure and is used to study the moments and forces acting on the cryostat. This model was developed for the relative ease of obtaining reliable verification studies. The shell model is a more complex simulation that includes the entire inner vessel, which contributes to the overall stiffness of the structure. This model was developed to provide detailed predictions of structural deformations as well as stresses on the frame and outer membrane. Its results are compared against the measured stresses to validate the cryostat behaviour for the sizing case (i.e., the cryostat full of LAr and at 350 mbarg over-pressure). It can predict strain and deformation during the three main phases: commissioning, filling with LAr, and operation. Figure 8 illustrates a possible deformation during standard operation. Note that the image vastly exaggerates the actual deformation.

Strain gauges and displacement sensors are installed at the positions where the simulation predicts the highest stresses. All sides of the cryostat are instrumented in similar locations to check the symmetrical behaviour of the structure.

Four displacement sensors, commonly known as Linear Variable Differential Transformers (LVDTs), are installed to monitor the symmetry and magnitude of the cryostat’s global deformation. A total of 55 strain gauges (SGs) are used to measure local deformation of the structure under stress. A detailed description of the instrumentation can be found in [11].

The sensors are read out continuously during cryogenics commissioning, in order to check whether the maximum stresses and strains are exceeded in the most loaded areas and whether the structure demonstrates elastic behaviour; monitor the maximum deformations and their symmetry; serve as a secondary safety indicator of abnormal cryostat behaviour during commissioning.

The ProtoDUNE-SP monitoring system is complemented by a pressure gauge to measure the pressure difference between the cryostat and the local atmospheric pressure, and four temperature sensors to monitor variations in the pit where the cryostat is installed and on the surface of its outer structure.

Pressure tests validate the safety of the cryostat under pressure so that work activities can proceed in and around it, and they provide a final leak check on the cryostat roof penetrations. The success of these tests is a fundamental prerequisite for the cryogenics safety permit approval, which is required for the start of the cryogenics commissioning.

In a first pressure test, with the cryostat still empty, the over-pressure is increased to 200 mbarg, then decreased in steps of 50 mbarg. The maximum value is that which allows testing of the overall structure while keeping the most stressed areas within the elastic range. This value must also be far below safety valve maximum pressure, which is set at 350 mbarg. A second pressure test is performed at the end of the cryogenics commissioning, before starting operations, with the cryostat 96% full of LAr. The cryostat pressure is increased up to an over-pressure of 280 mbarg, again in steps of 50 mbarg. When performed on ProtoDUNE-SP each test lasted a few hours and the maximal over-pressure remained stable for about an hour.

All tests performed during the validation campaign were successful and the FEA model reproduced the cryostat behaviour in all cases. The pressure tests demonstrated the elastic behaviour of the cryostat structure: strain gauges showed a clear linear relation with the pressure and returned to zero at the end of the cycle (see Figure 9). Identically instrumented locations on the different walls showed symmetric readings, with the exception of the wall with the closed TCO, where differences are expected.

The values of the displacement and strain gauges measured during the fill were compared to the FEA predictions and found to fulfill the safety requirements. This comparison also validated the FEA model itself, which was then used to predict the cryostat behaviour at the sizing case. The outcome of the simulation was compatible with both EU and U.S. standards, thus providing the final qualification of the inner and outer cryostat mechanical structures.

3.3 Cryogenics, Cooling and Purification System

The cryogenics system provides the equipment and controls for receiving the argon, for purging, cooling down, and filling the cryostat, for maintaining the LAr in the cryostat at the desired temperature, pressure and level, and for purifying the argon and maintaining the required operational purity. This system has been developed jointly by Fermilab and CERN, building on experience at Fermilab from the Liquid Argon Purity Demonstrator (LAPD) [12], the 35t prototype, and MicroBooNE, and at CERN from the WA105 113 Dual Phase prototype and the design and operation of large-volume noble liquid detectors. The designed system described in this section is or will be applied to both ProtoDUNEs, the Short-Baseline Neutrino Near Detector (SBND), and the DUNE Far Detector [13]. The Far Detector implementation will differ in that it will generate the liquid nitrogen locally in the underground area.

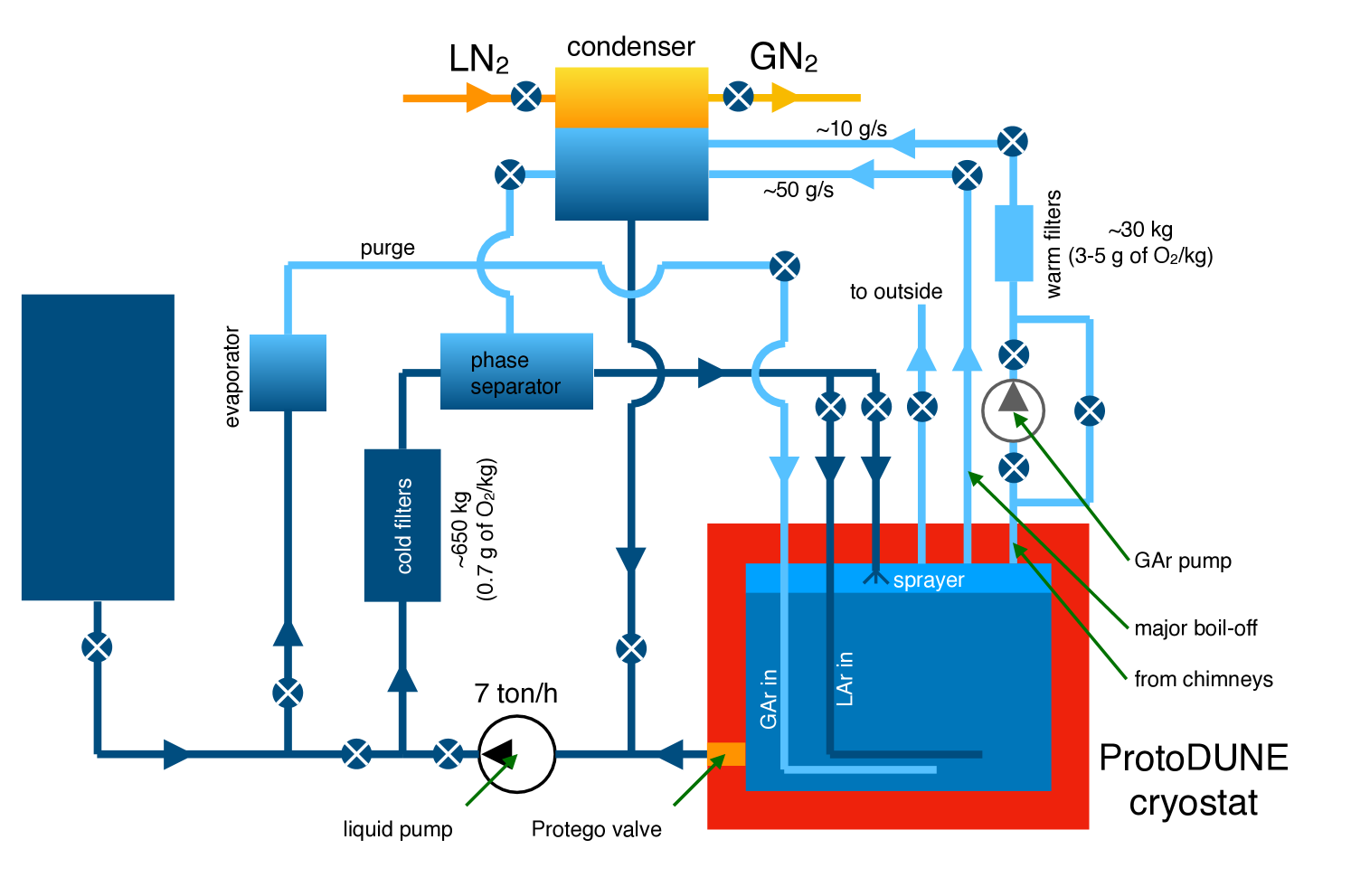

3.3.1 Overview

The Process Flow Diagram for the ProtoDUNE cryogenics system is shown in Figure 10. The cryogenics infrastructure is divided into three main parts: the external cryogenics located outside the building housing the detector, the proximity cryogenics located next to the cryostat, and the internal cryogenics located inside the cryostat. The external cryogenics facility includes the systems used for the receipt and storage of the cryogens used in the cryogenics system. Designed to serve both ProtoDUNE detectors, separate lines take LAr, GAr, and LN2 to both installations. A 50 m3 (70 t LAr capacity) vertical dewar was used to receive the LAr deliveries for the ProtoDUNE-SP initial filling period. The specifications for the oxygen, water, and nitrogen contamination in the delivered argon are 2, 1, and 2 ppm, respectively. An analyzer rack near the dewar was used to check the levels of these impurities in the delivered LAr batches and a 55 kW vaporizer was used to deliver the gaseous argon to the cryostat. LN2 deliveries were received and stored in a second 50 m3 vertical dewar (40 t LN2 capacity); the LN2 is used in cool-down and normal operations, as explained below. A m mechanical filter is located on the LAr feed line to prevent any impurities in the LAr supply from entering the purification system and the cryostat. Since a GAr/H2 mixture (2% H2) is used to regenerate the LAr and GAr purification filters, a separate 10 m3 storage dewar dedicated to this function connects to a cylinder of hydrogen (H2) and a GAr line.

To fulfill the LAr purity requirements, the LAr and the liquid boil-off needs to be collected, purified, and reintroduced into the system. The proximity cryogenics takes care of all actions during the recirculation of both in liquid and gas phase. The system comprises the argon condenser, the purification system for the LAr and GAr, the LAr circulation pumps, and the LAr/LN2 phase separators.

The recirculation done at the liquid phase represents the major flow. During normal operations, the continuous re-circulation rate was 7.0 t/h, giving a full volume turnover time of 4.6 days, which kept the impurity concentration below ppt oxygen equivalent. The LAr is transferred to the liquid purification system via external pumps located on one side of the cryostat more than 5 m below the liquid level to avoid cavitation or vapor-entrapment. This purification system further reduces the initial impurity levels. The system has two pumps available to ensure continuous operation during maintenance. Only one pump is in service at a time. The purification system consists of three filter vessels; the first contains molecular sieve (4 Å) to remove water, and the others contain alumina porous granules covered by highly active metallic copper for catalytic removal of O2 by Cu oxidization. In addition, m mechanical filters are installed at the exit of the chemical filters. Saturation of the chemical filter occurs when the trapped/reacted impurity budget exceeds the removal capacity of the filter material. At this point the LAr flow is brought directly to the mechanical filter and the regeneration of the saturated chemical filter can start. Filter regeneration typically takes two days, after which the system returns to nominal operation.

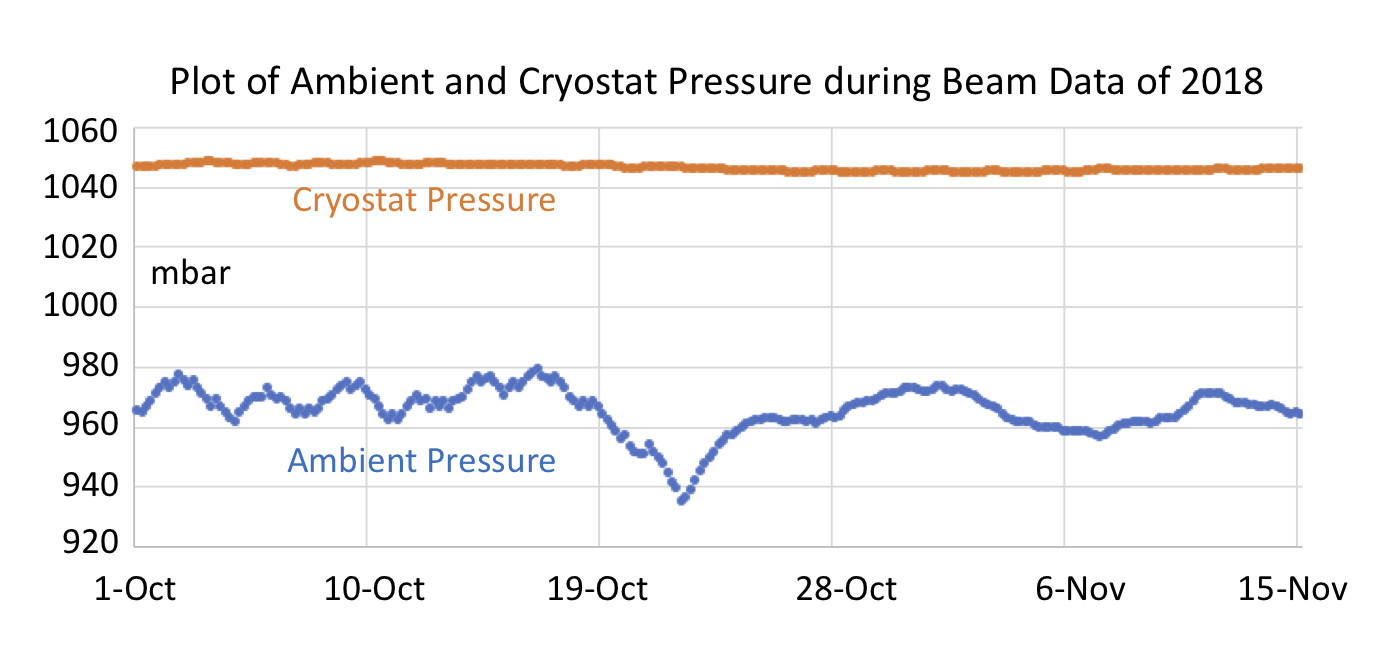

The second main flow is given by the recirculation of the gas boil-off. The LAr in the cryostat continuously evaporates at a slow rate due to unavoidable heat ingress. Therefore the boil-off is collected, condensed, purified, and reintroduced into the system. The main part of the argon vapour, roughly corresponding to 75% of the total boil-off, is collected via a dedicated penetration in the cryostat roof. The vapor is then directed towards the argon condenser, which is a heat exchanger that uses the vaporization of LN2 to provide the cooling power to condense the GAr. The newly condensed argon is then injected into the main liquid flow where it follows the liquid purification path carried out by means of the cold filters. About 15% of the argon boil-off is removed through purge pipes connected to each penetration on the roof. This portion of gas is driven towards a purification system at RT that is composed of chemical filters similar to those used for the liquid. The design has a diaphragm pump to raise the pressure of the gas and a pressure-control valve to continuously monitor the gas flow to the condenser and maintain the pressure within the cryostat. The standard operating pressure is 1050 mbar (absolute); on occasion the pressure was regulated on gauge from a minimum of 10 mbar above ambient to a maximum of 250 mbar. Under standard conditions the pressure regulation remains better than mbar.

The diaphragm pump failed at some point during operations. While this pump was bypassed, the flow of the argon gas was instead controlled by adjusting the pressure. This demonstrated that the diaphragm pump was not essential and highlights the importance of designing flexibilty into the cryogenics system.

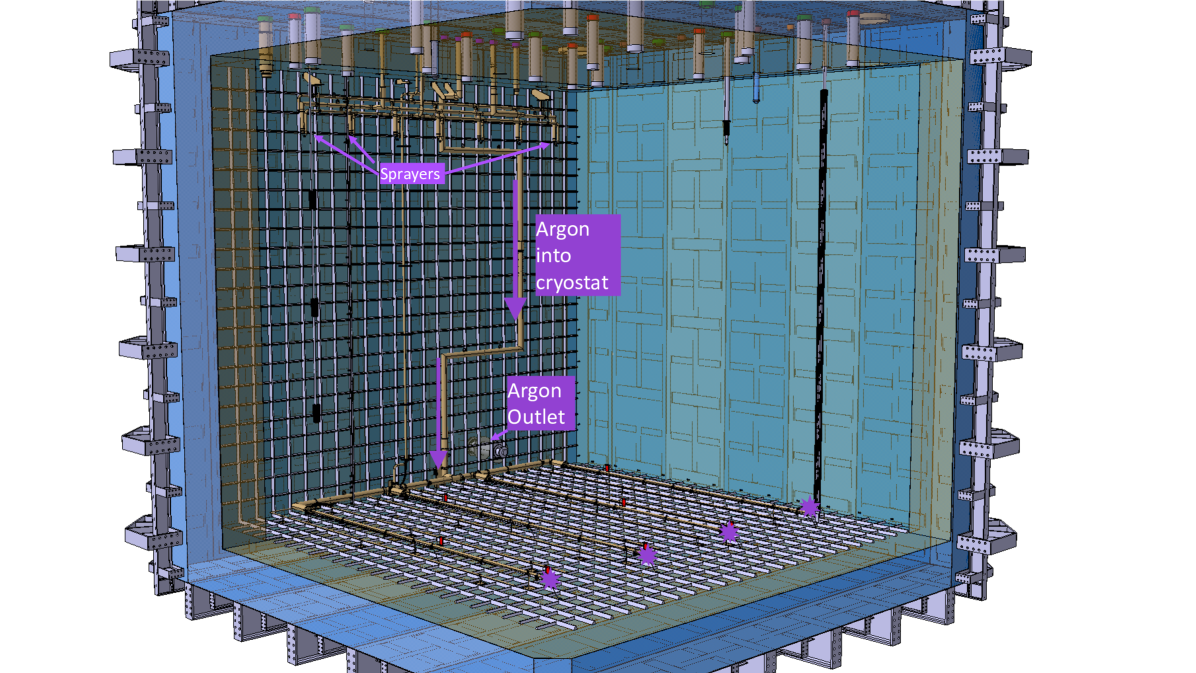

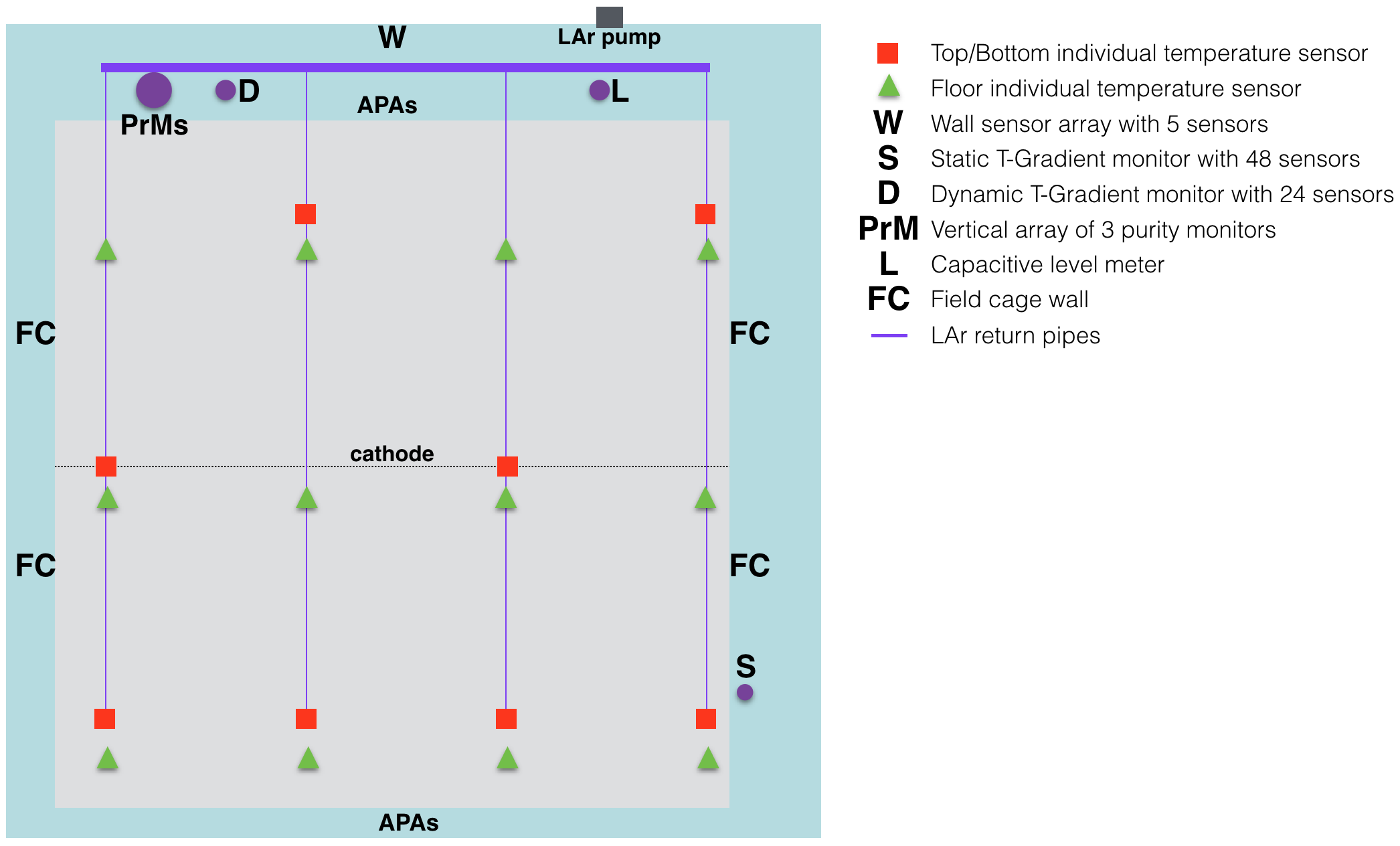

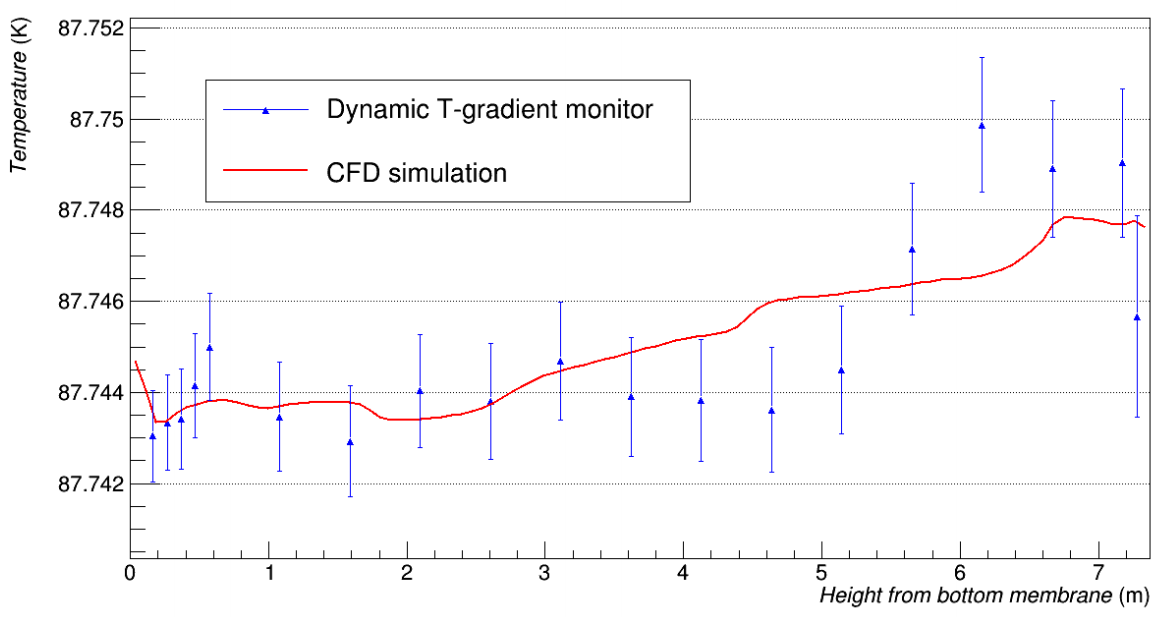

The internal cryogenics encompasses all the cryogenics equipment located inside the cryostat, including manifolds for the cool-down operation and for the distribution of the liquid and gaseous argon. The pipes for LAr distribution are positioned on the bottom of the cryostat and the outlets are at the end of the pipes, roughly opposite to the side penetration from which the purification system extracts the LAr (see Figure 11). The LAr entering the tank is warmer than the ambient by 0.4 K. This is a consequence of the isentropic efficiency of the LAr pump and the total heat load going to the transfer lines and valve boxes involved in the LAr circulation and purification processes. This temperature difference is crucial in that it induces an upward flow of the newly purified argon from its entry point at the bottom of the cryostat.

3.3.2 Phases of Operation

Once the cryostat construction and the installation of all scientific equipment is complete, the cryostat is cleaned (dust removal) in preparation for cool-down and fill. The first step is the purge in open loop (also called piston-purge) in which the atmosphere in the cryostat is replaced with argon gas. To ensure the purity of the input argon, the argon pipings are isolated, evacuated to less than 0.1 mbar absolute pressure, and back-filled with high-purity argon gas. This cycle is repeated several times to reduce contamination levels in the piping to the ppm level. The argon gas is then injected into the cryostat through a set of pipes at the bottom of the cryostat. The flow nozzles are directed downward to spread the gas across the bottom of the tank and produce a stable, upwardly advancing argon wave front. The exhaust is removed from the top using the main GAr outlet and vented outside of the building. A control valve regulates the pressure in the cryostat during this entire operation. The side purge lines located on each roof penetration are also used to evacuate the exhaust gas, ensuring that all volumes (especially trapped volumes) are properly purged. The vertical flow velocity of the advancing GAr is set to 1.2 m/h, which is twice the diffusion rate of the air downward. This causes the advancing pure argon-gas wave front to displace the air rather than just dilute it. After 44 hours (seven volume changes), the purge process is complete with residual air reduced to a few ppm.

The second stage of the purge process is done in “closed loop" for one week. During this stage the GAr is recirculated through the GAr purifier and sent back to the bottom of the cryostat. The gas purification system further removed the water-vapor outgassing from the FR4 circuit-board material and the plastic-jacketed power and signal cables present inside the cryostat. This closed-loop purge process further reduced the oxygen and water contamination inside the cryostat to sub-ppm and ppm-levels, respectively, at which point the cool-down could start. It also allowed assessment of the residual leak rate to atmosphere and the nitrogen content before cool-down.

The cool-down of the cryostat and detector is performed by flowing LAr and GAr into the cryostat through a manifold located near the top. Sprayers deliver a mix of LAr and GAr in atomised form that is distributed inside the cryostat by another set of GAr-only sprayers. During this operation the gas is exhausted using the pressure control valve, keeping the cryostat pressure at 70 mbarg. The sprayers guarantee a flat profile of the fluid (LAr and GAr) coming out, so as to meet the cool-down requirements of the cryostat and in particular those of the detector, which are more stringent. The maximum cool-down rate for the TPC is 40 K/h with a maximum temperature difference between any two points in the detector volume of 50 K.

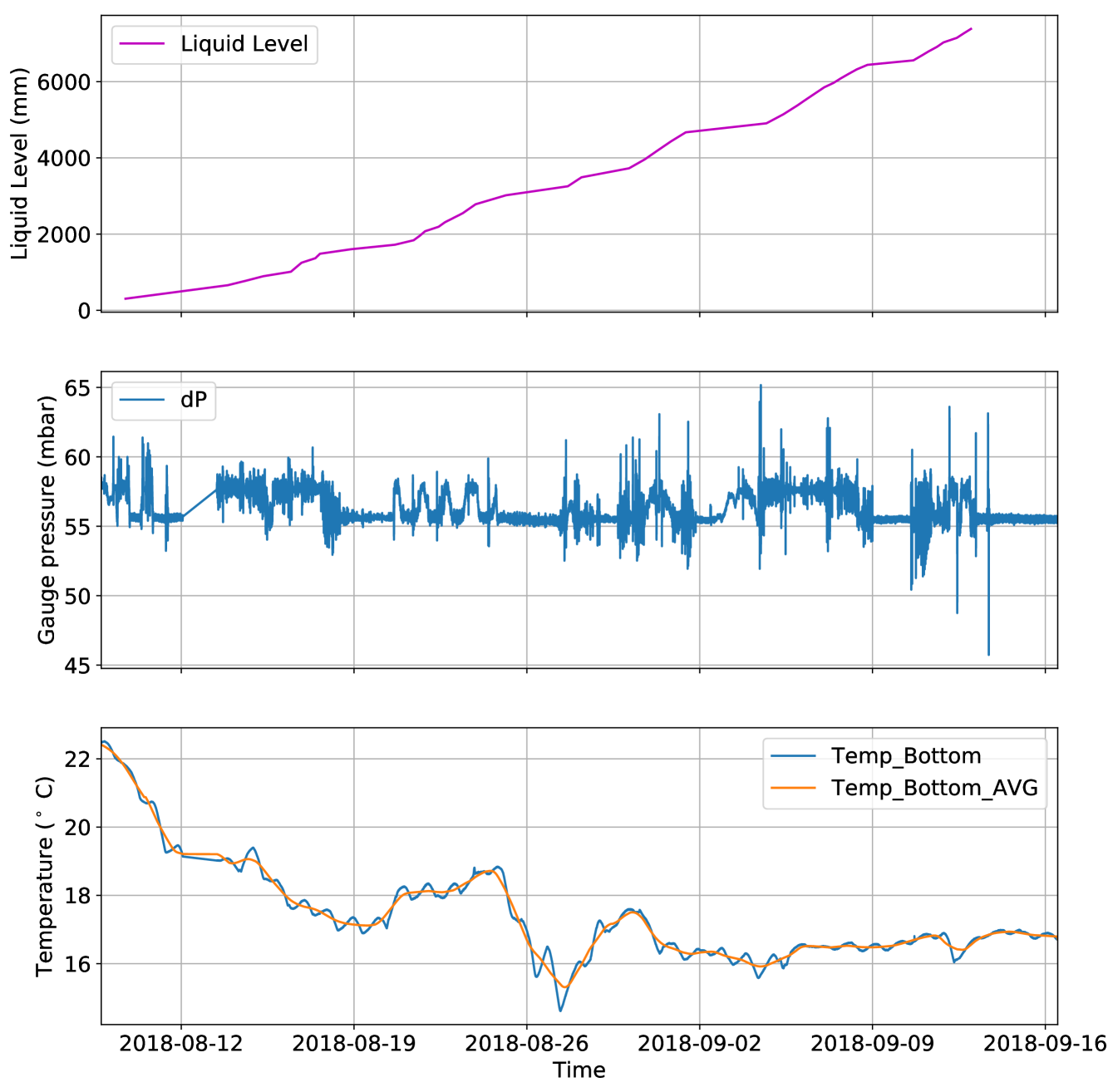

Once the cryostat and the TPC are cold, the fill starts. LAr is transferred through the cryostat-filling pipework from the 70 t LAr storage tank via the filtration system for purification and the LAr phase separator, which allow for the injection in the cryostat of argon in both liquid and gas phases. The ProtoDUNE-SP filling process took about six weeks. Figure 12 shows the liquid level, pressure, and temperature trends observed during the filling of the cryostat.

Once the cryostat is filled, the system can enter steady-state operation. During operation, as shown in Figure 10, the boil-off that passes through the purge pipes on the signal feedthroughs is filtered directly at room temperature and then condensed with the main boil off. Before being reintroduced in the cryostat as liquid, it is purified and mixed with the bulk of the LAr coming from the cryostat.

Table 1 lists the final parameters of the ProtoDUNE-SP cryogenics, Figure 13 shows the stability of the cryostat pressure against ambient pressure variations during the beam run period (October - November 2018). Table 2 shows the heat leak balance of the cryogenics system as measured during steady-state operations after the cryogenics cold commissioning.

| Liquid level | 7.45 m |

|---|---|

| Liquid volume | 540 m3 |

| Liquid mass | 752.76 t |

| Normal operating pressure | 1050.00 mbar |

| Circulation/purification process | 2150 W |

| Proximity cryogenics | 1200 W |

| Cryostat including top cap | 5170 W |

| Miscellaneous (cold electronic, cables, penetrations, rods, etc..) | 1980 W |

| TOTAL heat load | 10500 W |

At the end of operations the tank will be emptied and the LAr will be returned to the storage tank outside the building, and from there unloaded back to LAr trucks.

3.3.3 Cryostat Pressure Control

The pressure inside the cryostat is maintained within a very narrow range by a set of active controls. Pressure-control valves can increase or decrease the cooling power in the condenser by controlling the amount of LN2 flowing to the heat exchanger and the amount of GN2 that is vented. Other pressure-control valves can be used to vent GAr to atmosphere and/or introduce clean GAr from the storage, as needed.

During normal operation the pressure-control valves are set to control the internal cryostat pressure to mbar absolute. Excursions of a few percent from this value set off warnings to alert the operator to intervene, but more severe deviations (i.e., pressure exceeding 200 mbarg or going below 30 mbarg) trigger automatic actions: the system isolates the cryostat from any potential source of pressure, first closing the valves connecting the cryostat to the circuits used for gas make-up, purge, or cool-down, and the valve to the phase separator. Then the LAr circulation pump is stopped and the side penetration valves are closed.

If the pressure is too high, the system increases the LN2 flow through the heat exchanger inside the condenser and powers down any heat sources within the cryostat (e.g., detector electronics). At this point some of the GAr is vented to reduce the pressure in a controlled way. On the other hand if the pressure is too low, fresh GAr can be introduced into the cryostat through the GAr make-up line, a line dedicated to taking in argon directly from the outside supply.

The ability of the control system to maintain a set pressure is dependent on the size of pressure fluctuations (due to changes in flow, heat load, temperature, atmospheric pressure, etc.) and the volume of gas in the system. During normal operation ProtoDUNE-SP has 0.45 m of gas ullage at the top of the cryostat. This is 5% of the total argon volume and it is the typical vapour fraction used for cryogenic storage vessels. Reaction times to changes in the heat load are slow, typically on the order of one hour.

The cryostat is equipped with an additional high-integrity, mechanical, fail-safe over-pressure and under-pressure protection system capable of preventing catastrophic structural failure of the cryostat in any condition. The system is composed of a diverter valve connected to a set of two devices, combination pressure and vacuum safety valves (PSV/VSVs), located on the cryostat roof. Functions for both over- and under-pressure are combined in a single device for efficiency. One of the two identical devices in the system is installed in service mode and the other in stand-by, to guarantee that one is always active in case, for example, maintenance is required.

The device in service monitors the differential pressure between the inside and the outside of the cryostat and opens rapidly when the differential pressure is outside a preset range. In case of excessive pressure, the PSV/VSV opens and argon is released. The pressure within the cryostat falls and argon gas discharges into the argon vent riser. The valve is designed to close when the pressure returns below the preset level. In case the pressure detected is too low, the PSV/VSV opens and allows air to enter the cryostat to restore a safe positive pressure.

3.3.4 Cryogenics Control System

The cryogenics control system is a fully automated system that enables continuous cryogenic operation through the various modes of operation described in Section 3.3.2, while allowing manual actions by the operator as needed. It is a modular system, both in terms of the electrical and control hardware and the process control programming.

This system’s combination of automated and manual operation allowed its implementation at an early stage of the project, i.e., before the project inputs were fully defined, and enabled adjustments as the process and instrumentation evolved. It also made it possible to commission the cryogenics system in batches, i.e., to operate in one mode while implementing the control programming for the next mode.

The electrical and control architecture is based on a functional analysis of the cryogenics system and the subsequent Product Breakdown Structure (PBS), Piping and Instrumentation Diagram (P&ID), parts list (detailing the characteristics of the instrumentation), and process logics specification. The hardware architecture consists of three different hardware installations, each controlled by a dedicated Programmable Logic Controller (PLC) Siemens s317, remote input/output modules (I/O), and control cabinets. Each hardware installation corresponds to one of the three main cryogenics subsystems, namely, the external infrastructure for the storage and the proximity system for the two ProtoDUNE cryostats. Each control cabinet is dedicated to a specific function, e.g., LAr/nitrogen management, purification, phase separation, condensing, argon circulation. Each cabinet includes industrial cryogenics instrumentation: actuators (valves, pumps) and sensors. The infrastructure for the ProtoDUNE-SP hardware installation includes a total of 10 control cabinets and 630 signals.

The control system software was developed using the UNIfied Industrial COntrol System (UNICOS) [14]. The software architecture relies on a Process Control Object (PCO) breakdown structure. The process logic specification used as basis for the programming was designed with a modular structure and relies on associated option modes, sequencers, and interlocks. The option modes of the master PCO correspond to the sequence of operations of the cryogenics system, namely, default (which covers the fall-back situation with the cryostat pressure protection always active), open-loop purge, closed-loop purge, cool-down, fill, steady-state, and emptying. These option modes are used either to switch on a set of dependant units fulfilling the function for a given stage of operation or to set a collection of states of the controlled objects, e.g., fixed position or regulation mode for a valve, or a set-point.

In case of abnormal behaviour, software interlocks prevent any further automatic actions. The specifications and programming were completed and implemented sequentially, in batches corresponding to the operation modes. This allowed starting safely with an incomplete system, continuing to program while the system was already in operation, and adjusting the program as needed during commissioning.

The system is equipped with several features to ensure safe and continuous cryogenics operation, maintainability, and to provide flexibility for system evolution. For example, all equipment essential to the functioning of the system is powered from redundant electrical power supplies, including Uninterruptable Power Supplies (UPS) and diesel generators. Vacuum enclosures placed in the cryostat pit are constantly monitored. A degraded vacuum could signal a potential argon leak, therefore an alarm would be raised to indicate this condition.

3.3.5 Cryogenics Commissioning

Quality assurance and quality control were performed during the design, construction, installation and commissioning phases. During the construction and installation phases, non-destructive tests (X-rays, He leak tests and pressure tests) were successfully executed. During cold commissioning another series of tests was completed successfully, the main two of which were a check of the I/O signals and a functional test of all valves and equipment. The I/O check consisted of verifying all connections and the synchronisation of the 630 signals, testing the response to actions like opening/closing valves and to sensor readings, and verifying the sensor calibration or run calibration sequence for each control valve. In addition, tests were run on the Ethernet or hardwired signal lines dedicated to the exchange of information between the cryogenics system and the detector system, the safety system, and the CERN Central Control room.

A ‘mirror’ station (not connected to the actual field equipment) provided a functional test environment for the process control logic. The tests were subsequently carried out on the real system to verify first alarms, interlocks, and the sequential function charts. Operation modes were tested afterwards, during the system commissioning.

4 Detector Components

4.1 Inner Detector: High Voltage

A liquid argon time projection chamber (LArTPC) requires an equipotential cathode plane at high voltage (HV) and a precisely regulated interior electric field (E field) to drift electrons from particle interactions to sensor planes. The ProtoDUNE-SP LArTPC consists of a vertical cathode plane assembly (CPA), vertical anode plane assemblies (APAs), and sets of conductors surrounding the drift volume that are collectively called the field cage (FC). The FC provides a graded voltage profile between the CPA and APA in order to produce a uniform E field in the drift volume.

Figure 14 shows the TPC configuration. Six top and six bottom FC modules connect the horizontal edges of the CPA and APA arrays, and four endwalls connect the vertical edges (two per drift volume). Each endwall is composed of four endwall modules. A Heinzinger -300 kV 0.5 mA HV power supply delivers voltage to the cathode. Two HV filters in series between the power supply and HV feedthrough filter out high-frequency fluctuations upstream of the cathode.

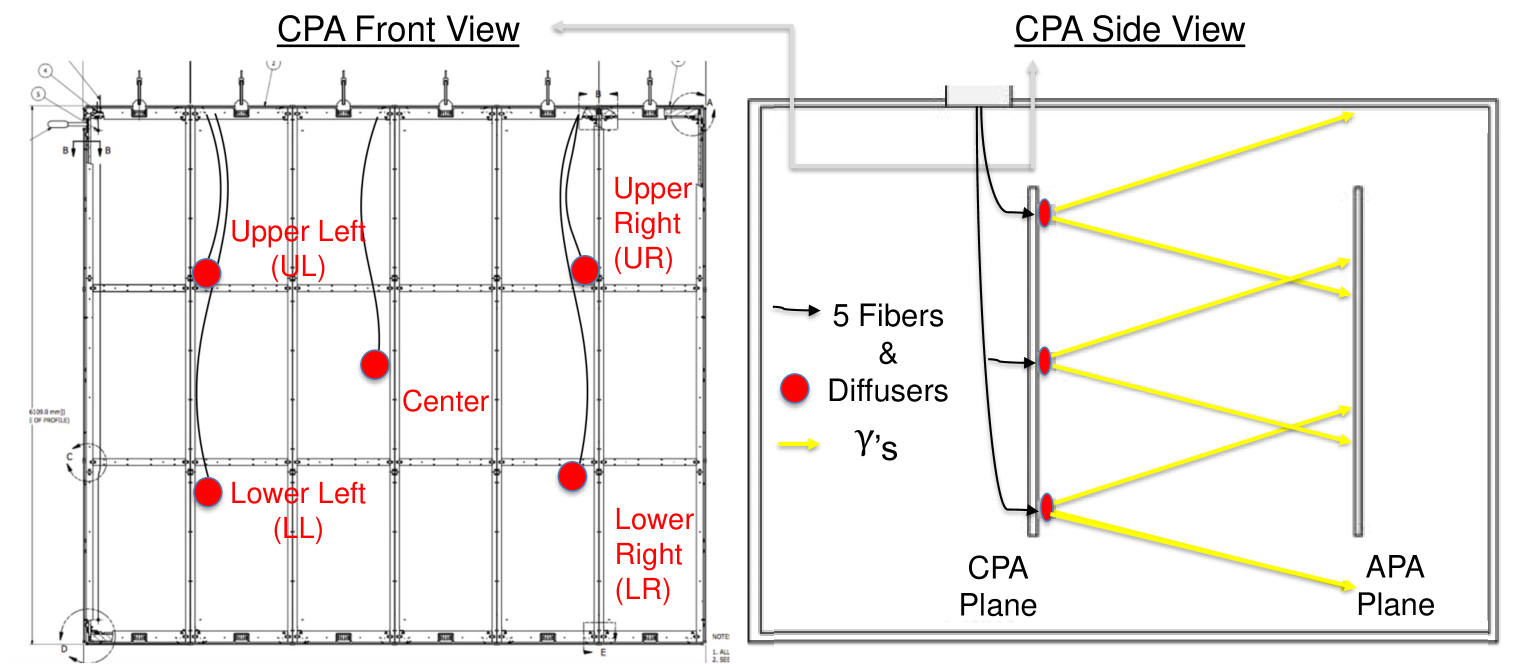

4.1.1 Cathode Plane Assembly (CPA)

The CPA is located in the middle of the TPC, dividing the detector into two equal-distance drift volumes. The CPA’s 7 m 6 m area is made up of six panels, each of which is constructed of three vertically stacked modules. The same modular structure and materials will be used in the far detector design. The scope of the ProtoDUNE-SP CPA includes:

-

•

18 CPA modules, each with a frame and resistive sheet,

-

•

HV bus connecting the resistive sheets and modules, and

-

•

HV cup for receiving input from the power supply.

Several requirements are placed on the HV system. Electrically, the CPA must provide an equipotential surface at 180 kV nominal bias voltage that remains stable for data taking. The resistive sheet must provide slow discharge of accumulated charge in the event of an unexpected HV breakdown, to prevent damage to the readout electronics. To ensure a uniform drift field, the flatness must remain to within 1 cm while submerged in LAr. Mechanically, the CPA needs to support the full weight of the four connected top and bottom FC modules, as well as that of a person during the installation. It must allow for cryostat roof contraction during the cool-down to LAr temperature. Furthermore, it must be constructable within the cryostat, and its materials must inhibit trapped LAr volumes.

CPA design

The cathode plane surface is made of a resistive material, which, in the event of HV breakdown at a point on a CPA module, will restrict the sudden change in voltage to a relatively localised area, thus preventing discharges from potentially damaging either the cold electronics (CE), the cryostat, or the capacitively coupled anode planes. The rest of the CPA maintains its original bias voltage, and gradually discharges to ground through the high resistivity of the cathode material.

The 18 CPA modules are constructed of strong 6 cm thick FR4 (the fire-retardant version of G10) frames. The frames hold 3 mm thick FR4 sheets laminated on both sides with a commercial resistive Kapton film of type D11261075 [15]. Each CPA module is 1.16 m wide and 2 m high, and they stack three high to form a CPA panel of height 6 m. The CPA plane consists of six panels placed side-by-side and has the same dimensions as each of the two APA planes.

The surface of the frame facing the APAs is covered by a set of resistive FR4 strips with a bias voltage different from that of the CPA resistive sheets, chosen such that the frame itself causes no distortion in the drift field.

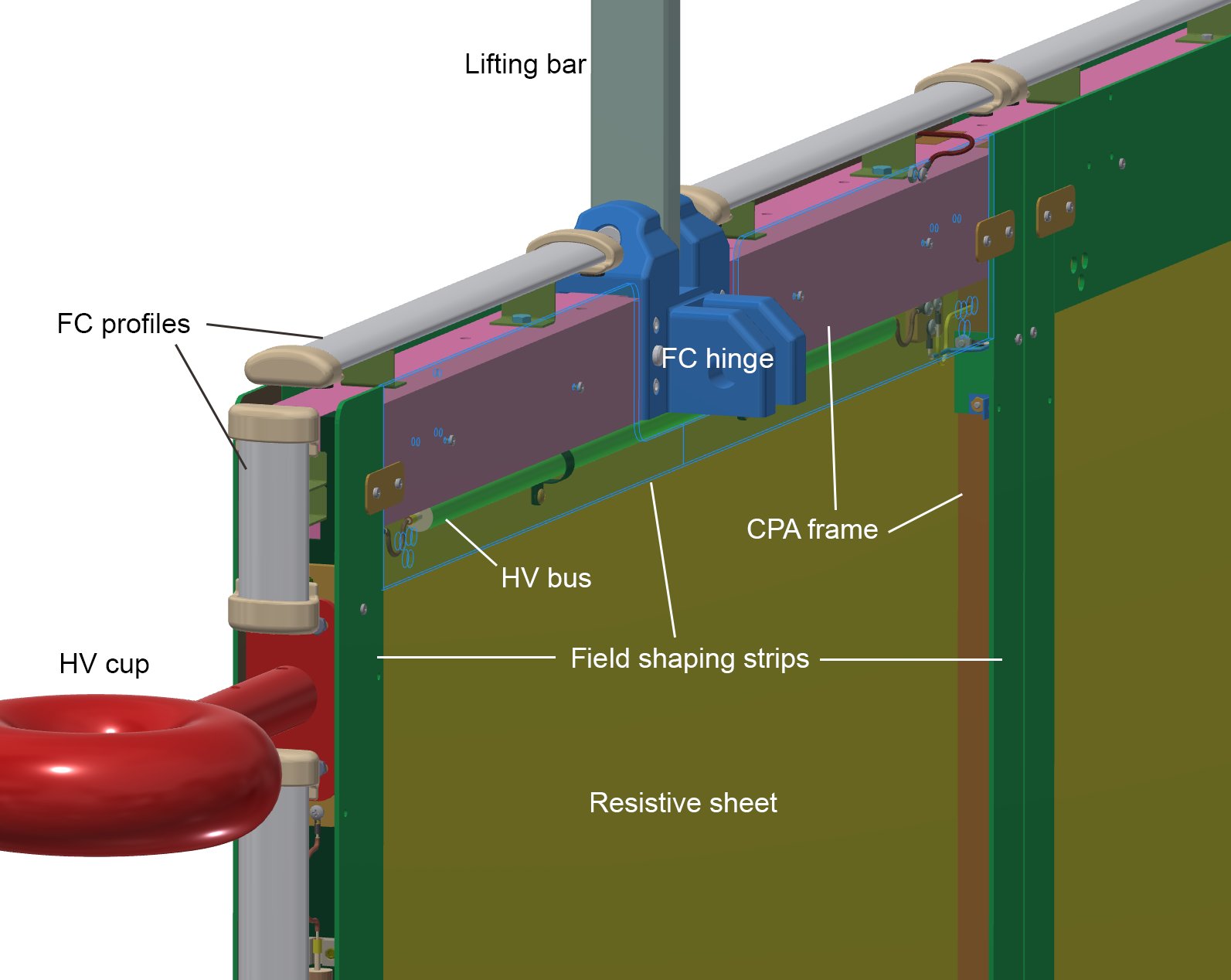

The outer edges of the cathode plane facing the cryostat wall are covered with the same metal profile assemblies as used in the field cage (FC), described in Section 4.1.2. This limits electric field strength to below 30 kV/cm, as required, in the areas around the CPA frame and eliminates the need for a special design of these most crucial regions of the cathode plane. The edges of the CPA are effectively a continuation of the FC, as shown in Figure 15. Since the FC profiles are the only objects facing grounded surfaces, they are the most likely candidates for HV discharges to ground. To limit peak current flow, these edge profiles are connected to the field-shaping strips by means of a wire jumper.

The CPA is connected to the HV feedthrough through a receptacle, called the HV cup as shown in Figure 15, at the downstream side of the cryostat (with respect to the beam entrance) and biased at 180 kV. It provides the voltage and the required current to all the FC modules (top, bottom, and end walls) through electrical interconnects (Section 4.1.2).

The design takes into account deformation and stress due to the pressure from the circulating LAr as well as shrinkage due to the temperature change. For example, to ensure contact between the CPA modules after cool-down, a gap of 0.7 mm, corresponding to the calculated amount of separation that contraction will remove as they cool down, has been introduced. The joints between the FC and the CPA are also designed to accommodate an estimated shrinkage of 5.2 mm of the steel supporting beam between the CPA and APAs.

Mechanical and electrical interconnections between modules

Three modules are stacked vertically to form the 6 m height of a CPA panel as shown in Figure 16. The frames of these modules are bolted together using tongue-and-groove connections at the ends. The resistive cathode sheets and the field-shaping strips are connected using metallic tabs to ensure redundant electrical contact between the CPAs.

Each CPA panel is suspended from the cathode rail using a central lifting bar. Due to the roof contraction as the cryostat is cooled, it was calculated that each CPA would move 2 mm relative to its neighbours. Several pin-and-slot connections are implemented at the long edges of the CPA panels to ensure the co-planarity of the modules while allowing for a small vertical displacement.

The electrical connectivity of the resistive sheets within a CPA panel is maintained by several tabs through the edge frames. The voltage is passed from one CPA panel to another through embedded cables in the panels, referred to collectively as the HV bus, as shown in Figure 15. Redundant connections in the HV bus between CPA panels are used to ensure reliability. The HV bus also provides a low-resistance path for the voltage needed to feed the FC resistive divider chains. The required connections to the FC modules are made at the edges of the CPA. Along its perimeter, the HV bus cables are hidden between the field-shaping strip overhang and the main cathode resistive sheet. The cables are capable of withstanding the full cathode bias voltage to prevent direct arcing to (and as a result, the recharging of) a CPA that discharges to ground. Connections are flexible in order to allow for FC deployment, thermal contraction, and motion between separately supported CPA components.

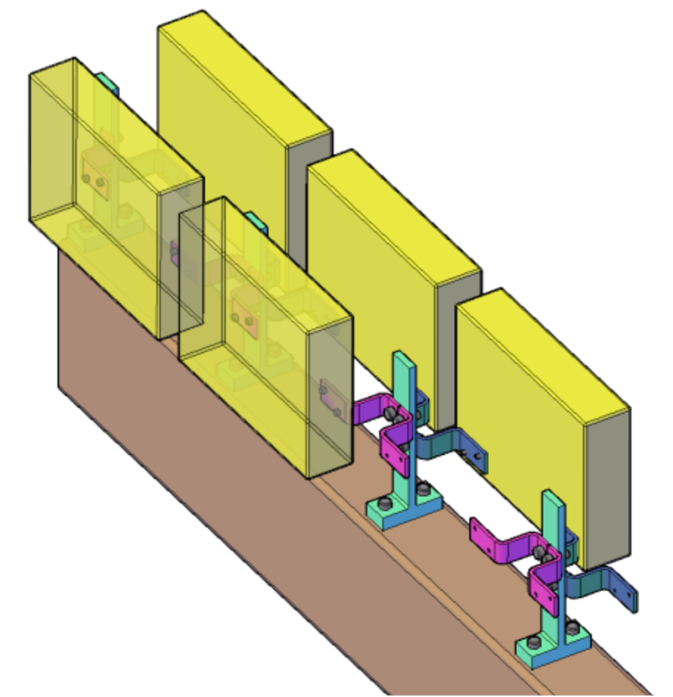

4.1.2 Field Cage (FC)

The FC covers the top, bottom, and endwalls of all the drift volumes, thus providing the necessary boundary conditions to ensure a uniform electric field and shielding it from the cryostat walls. The FC is made of adjacent extruded aluminum profiles running perpendicular to the drift field and set at increasing potentials along the 3.6 m drift distance from the CPA HV (-180kV) to ground potential at the APA planes. Other elements of the FC are the ground planes (GP) sitting above the top and below the bottom FC modules. They confine the electric field in the liquid phase, avoiding high field both in the gas phase at the top of the cryostat and close to the piping at the bottom. The structures holding the profiles are made of insulating fibreglass-reinforced plastic (FRP). FRP has good mechanical strength at cryogenic temperatures and low coefficient of thermal expansion. The FC modules come in two distinct types: the identical top and bottom modules, which run the full length of the detector, and the endwall FC modules, which are installed vertically to close the detector drift volume at either end.

The FC is divided into mechanically and electrically independent modules, which comes with several advantages. As a consequence of electrically subdividing the modules, the stored energy and therefore the risk of detector damage is limited. In addition, the division acts as a protection from transient surges. FC modules have their own, independent voltage divider network providing the necessary linear voltage gradient. In case of a resistor failure in a divider chain field, distortions would be restricted to the FC module concerned. The mechanical subdivision simplifies construction and assembly of the FC.

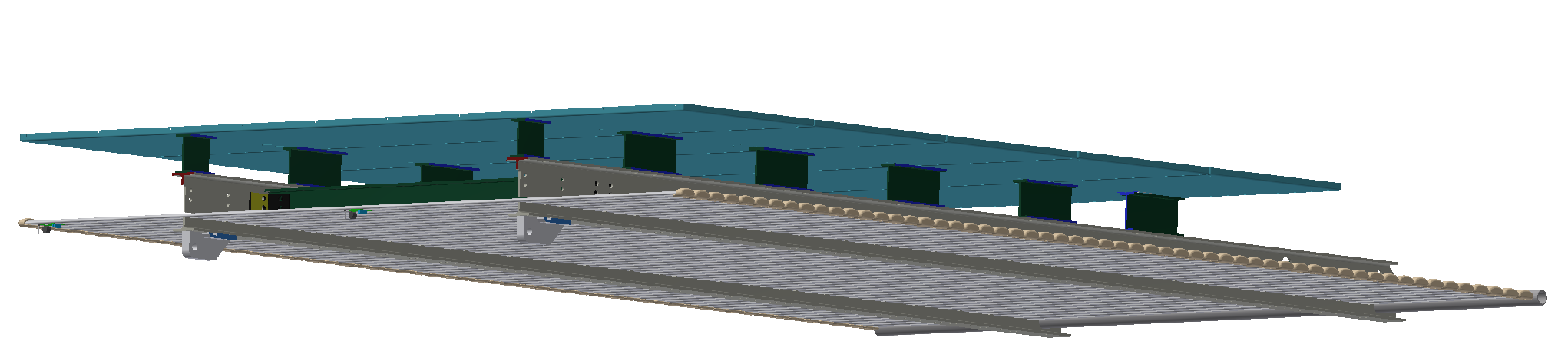

Top/Bottom Field Cage and Ground Planes

There are six top and six bottom FC assemblies, all like the one shown in Figure 17. The assemblies are constructed from pultruded FRP I-beams and box beams that support the aforementioned aluminum profiles. The length and width are 2.3 m and 3.5 m, respectively, each assembly comprising 57 aluminum profiles. A GP consisting of modular perforated stainless steel sheets runs along the outside surface of each top and bottom FC with a 20 cm clearance. The gas region at the top of the volume, also referred to as the ullage, which is necessary for safe and stable operation of the LAr cryogenics system, contains many grounded conducting components with sharp features near which the electric field could easily exceed the breakdown strength of gaseous argon if directly exposed to the energised FC. The GP protects against this. The bottom FCs are equipped with GPs to shield from cryogenic piping and other sensors with sharp features on the cryostat floor.

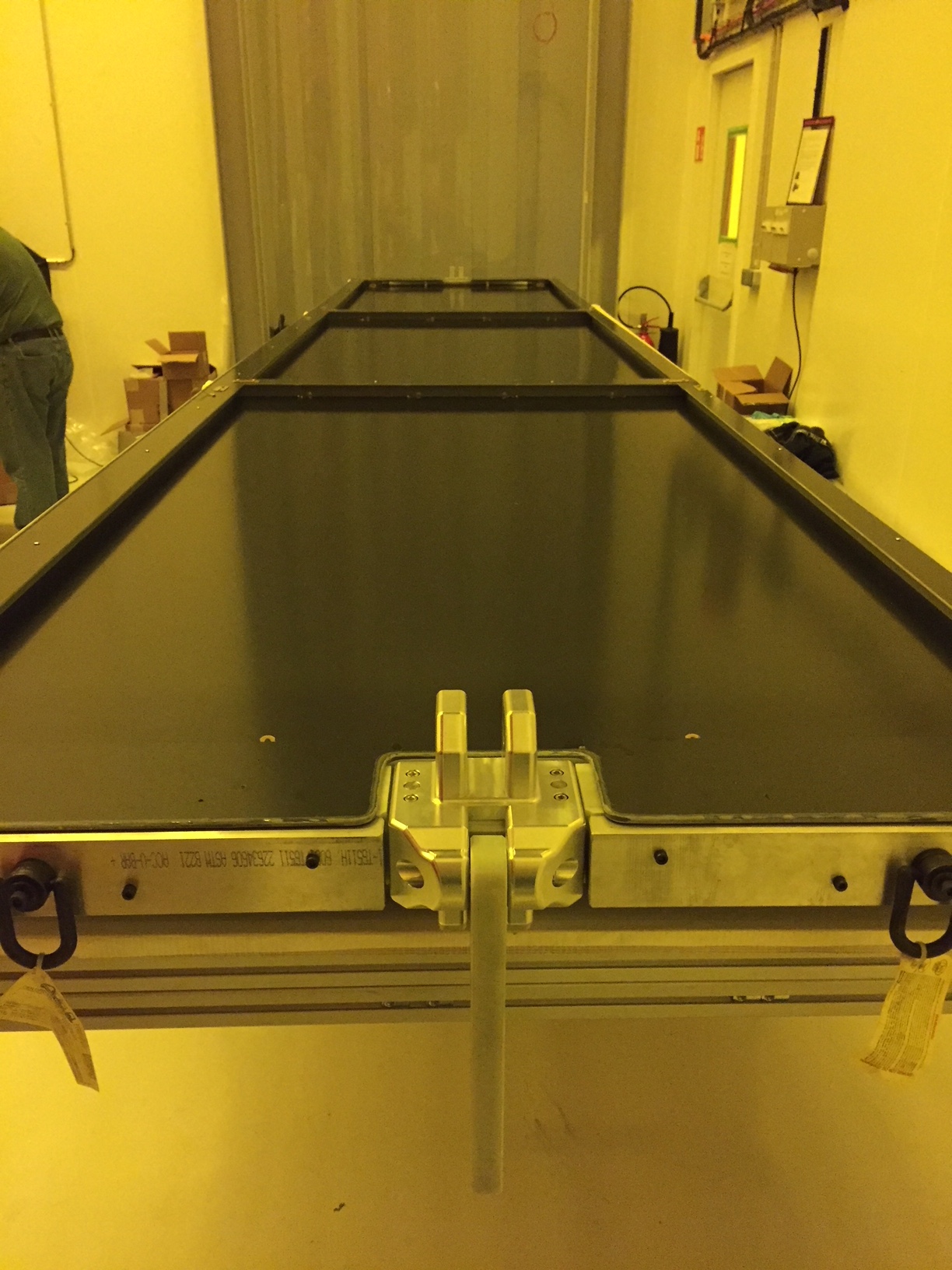

The connections between the top and bottom FC modules and the CPAs are made with aluminum hinges 2.54 cm in thickness that allow the modules to be folded in on the CPA during installation. The hinges are electrically connected to the second profile from the CPA. The connections to the APAs are made with stainless steel latches that are engaged once the top and bottom FC modules are unfolded and fully extended towards the APA. A top FC module being lifted for installation on the CPA panel is shown in Figure 18.

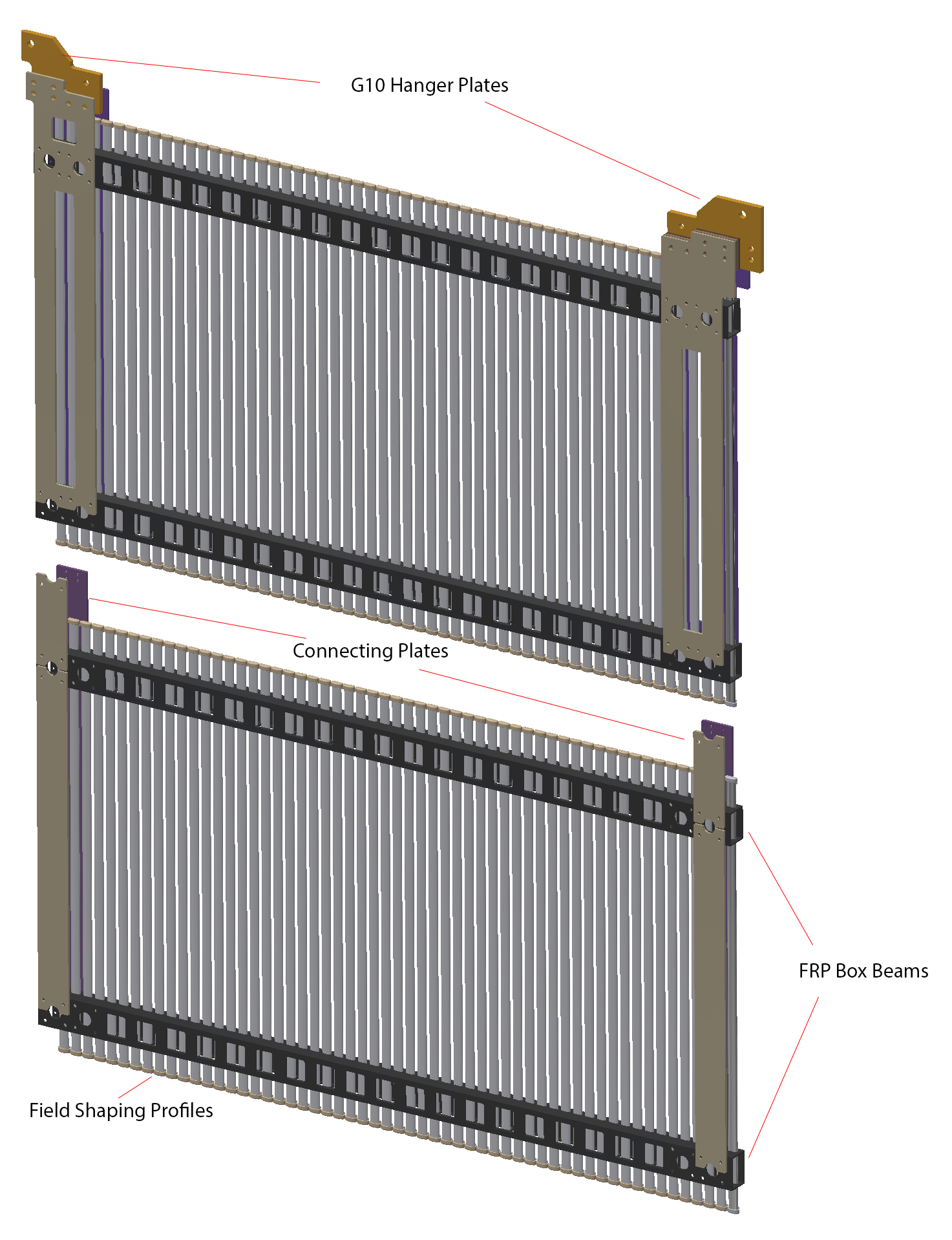

Endwall Field Cage

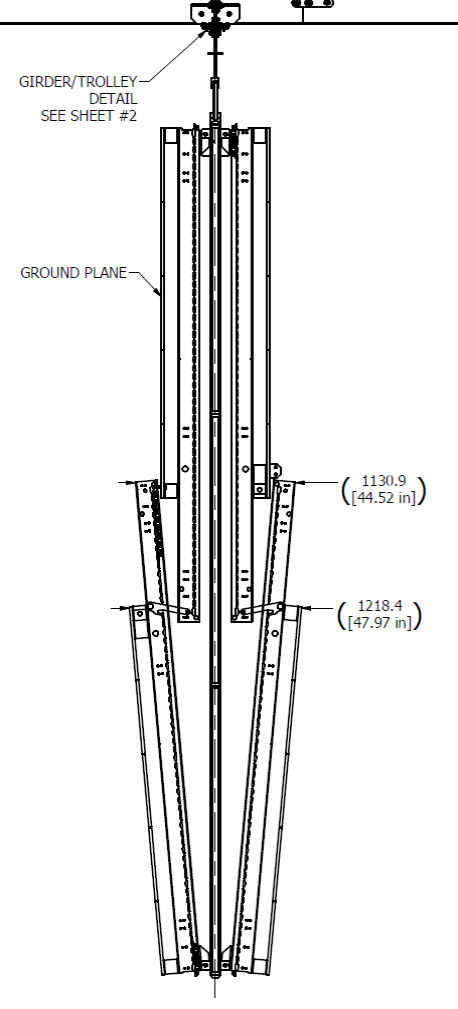

Each of the two drift volumes has two endwall FCs one on each end. Each endwall FC is in turn composed of four stacked endwall FC modules, the topmost equipped with hanger plates. Each endwall FC module is constructed of two FRP box beams each 3.5 m long as shown in Figure 19 (dark grey) and Figure 20. The endwalls are not equipped with GPs as there is enough side clearance between the cryostat wall and FC, thus avoiding high E-fields. In ProtoDUNE-SP the endwall at the beam entry point is customized to hold the beam plug, described in Section 4.1.3.

Field Cage Profiles

The FC modules consist of extruded aluminum field-shaping-profiles. The profile shape minimises the electric field strength between a given profile and its neighbours and between a profile and other surrounding parts. The profile ends have a higher surface electric field, especially those at the corners of the FC (boundary with APA or CPA). To prevent HV breakdowns in the LAr, the ends of the profiles are encapsulated by custom UHMWPE (Ultra-High-Molecular-Weight Polyethylene) caps. The caps are designed and experimentally verified to withstand the full voltage across their thickness.

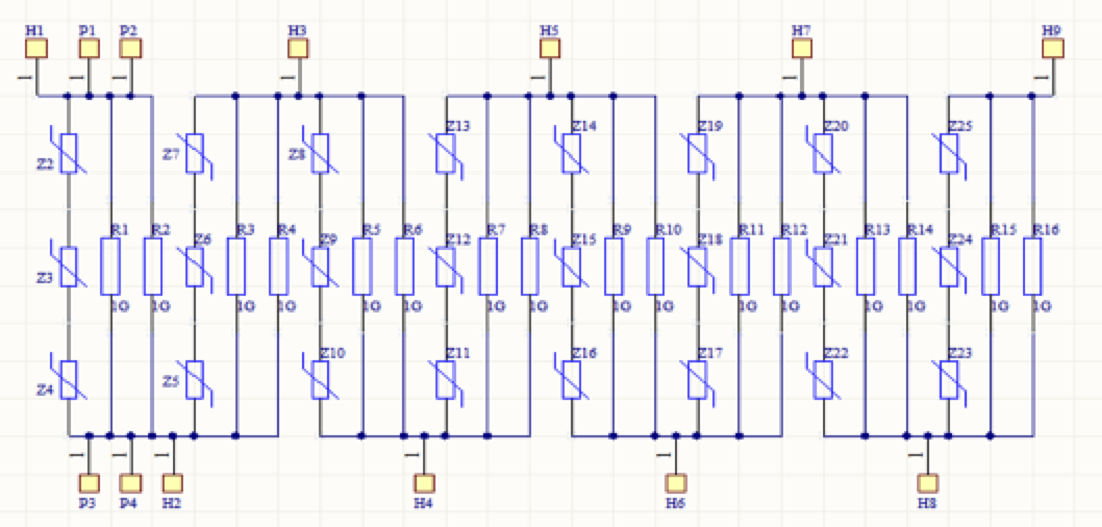

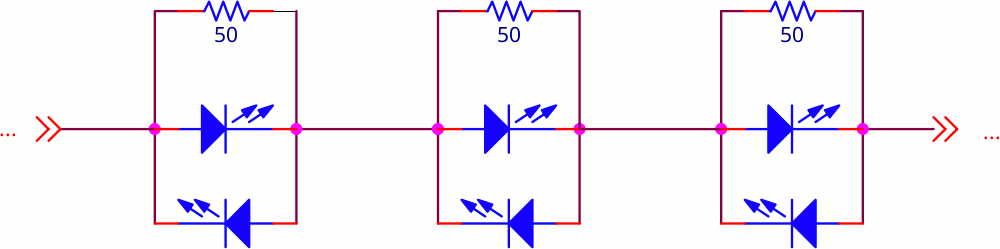

Voltage Divider Boards and Terminations

A resistive divider chain interconnects all the metal profiles of each FC module to provide a linear voltage gradient between the cathode and anode planes.

The resistive divider chain is a chain of resistor divider boards each with eight resistive stages in series. Each stage (corresponding to a 6 cm distance between FC profile centers) consists of two 1 G resistors in parallel yielding a parallel resistance of 0.5 G per stage to hold a nominal voltage difference of 3 kV. In the event of a HV breakdown, each stage is protected against HV discharge by varistors. Three varistors (with 1.8 kV clamping voltage each) are wired in series and placed in parallel with the associated resistors. A photo and schematic of the resistor divider board are shown in Figure 21. Each FC divider chain connects to an FC termination board in parallel with a grounded fail-safe circuit at the APA end. The FC termination boards are mounted on the top of the upper APAs and the bottom of the lower APAs. Each termination board provides a default termination resistance, and an SHV cable connection to the outside of the cryostat, via the CE signal feedthrough flange, through which it is possible to either supply a different termination voltage to the FC or monitor the current flowing through the divider chain, or both.

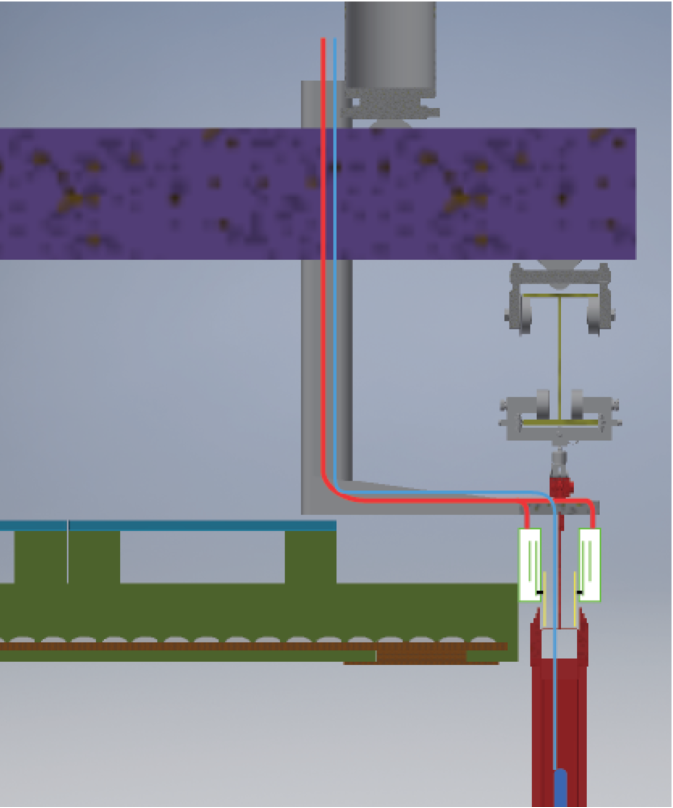

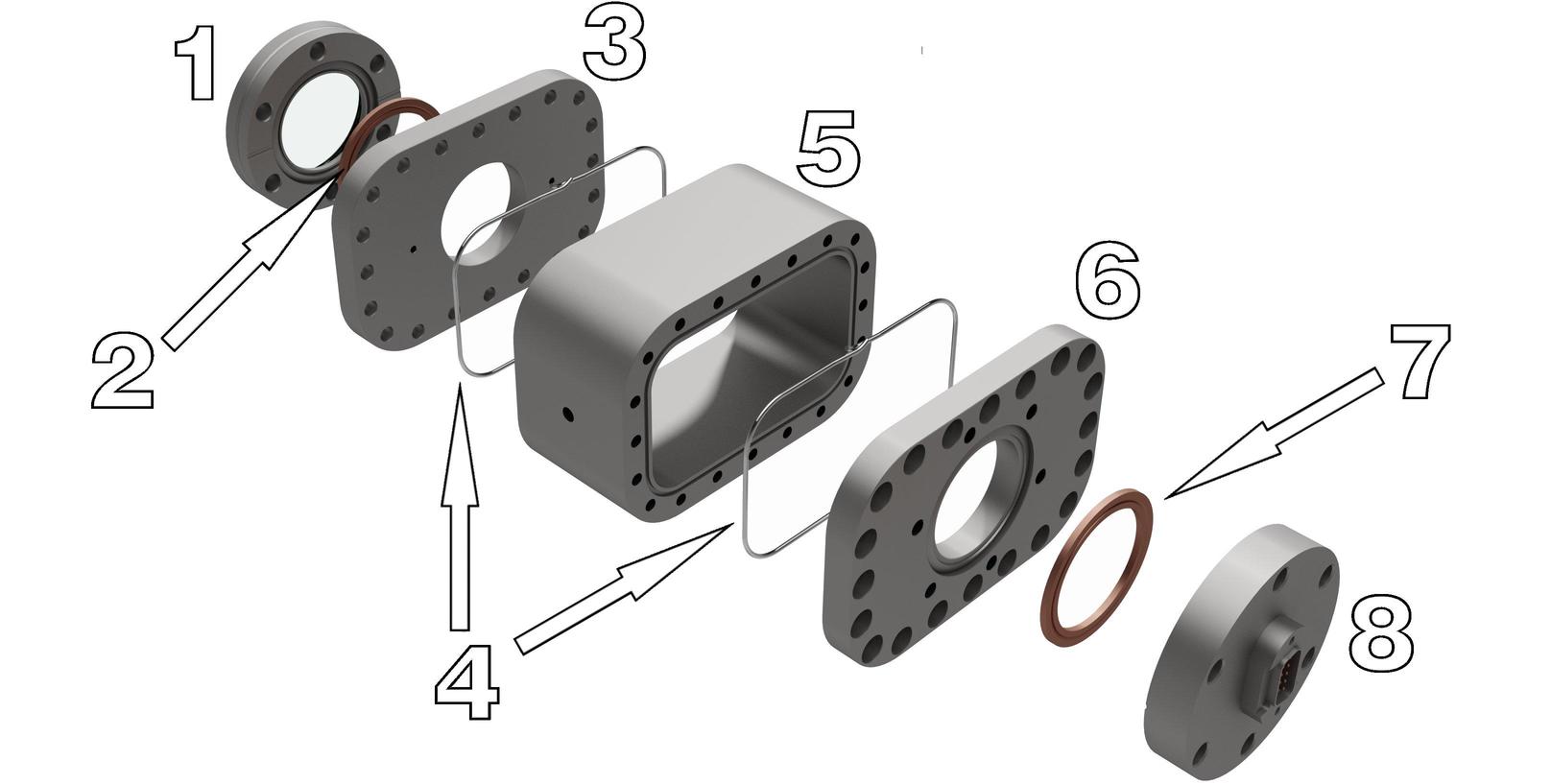

4.1.3 Beam Plug

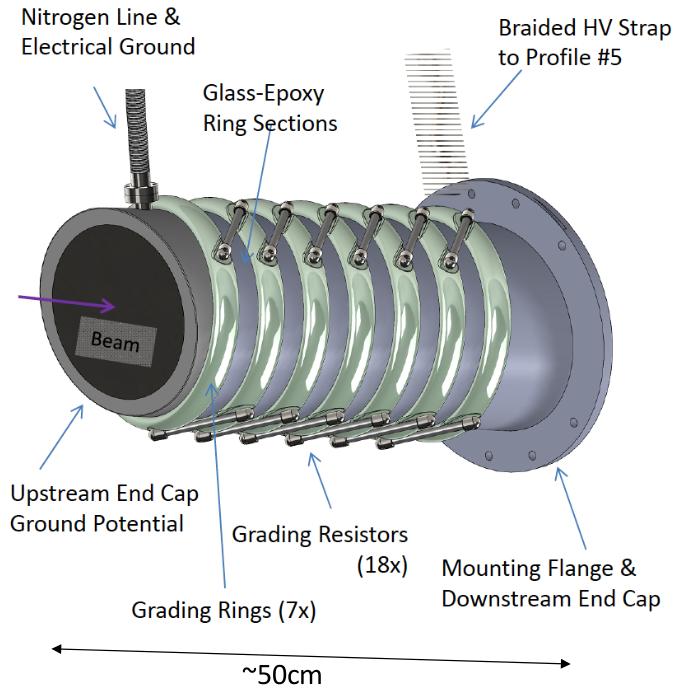

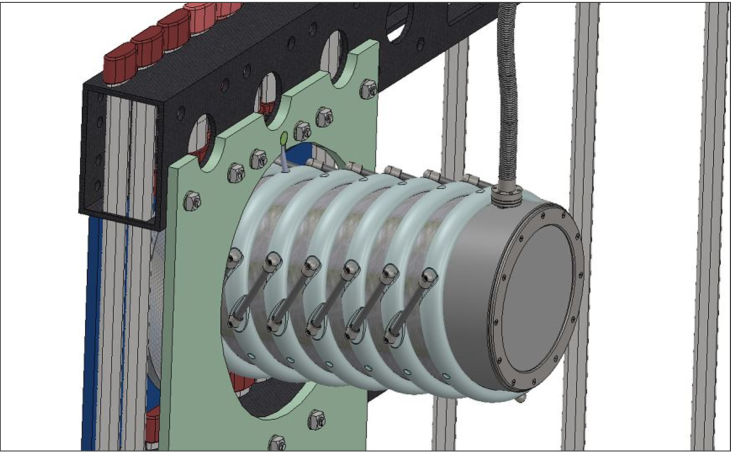

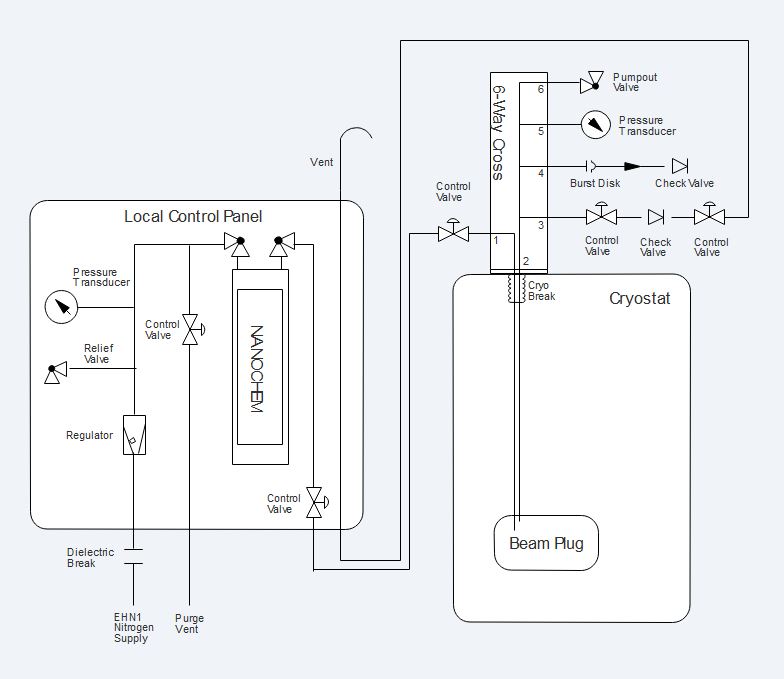

To minimise the material interactions of the particle beam in the cryostat upstream of the TPC, a volume of LAr along the beam path (between the cryostat inner membrane and the FC) is displaced, and replaced by a less dense volume of dry nitrogen gas. The gas is contained within the beam plug, a cylindrical glass-fiber composite pressure vessel, about 50 cm in length and 22 cm in diameter. It is illustrated in Figure 22. A pressure relief valve and a burst disk are installed on the nitrogen fill line on the top of the cryostat (externally) to ensure the pressure inside the beam plug does not exceed the safety level of about 22 psi. The nitrogen system schematic is shown in Figure 23.

The beam plug is secured to the endwall FC support structure as illustrated in Figure 22. Beam is fed into one of the two available drift volumes of the TPC, the drift volume not receiving beam is used for cosmic ray studies. The front portion of the beam plug extends 5 cm into the active region of the TPC through an opening in the FC. The FC support is designed with sufficient strength and stiffness to support its weight. The total internal volume of the beam plug is about 16 liters.

The requirements on the acceptable leak rate is between scc/s and scc/s. This is very conservative and is roughly equivalent to leaking 15% of the nitrogen in the beam plug over the course of a year. In the worst-case scenario in which all the nitrogen in the beam plug leaks into the LAr cryostat, the increase in concentration is about 0.1 ppm, which is still a factor of 10 below the maximum acceptable level, as specified by light-detection requirements. Over the course of about 1.5 years of beam plug operations in LAr at ProtoDUNE-SP, no detectable leak was observed.

At nominal operation, the voltage difference across the beam plug (between the first and the last grading ring) is 165 kV. To minimise risk of electrical discharges, the beam plug is divided into sections, each of which is bonded to stainless steel conductive grading rings. The seven grading rings are connected in series with three parallel paths of resistor chains. The ring closest to the FC is electrically connected to one of the FC profiles. The electrode ring nearest the cryostat wall is grounded to the cryostat (detector) ground. The maximum total power dissipated by the resistor chain is about 0.6 W.

4.1.4 High Voltage (HV) Components

The TPC high voltage (HV) components include the HV power supply, cables, filter circuit, HV feedthrough, and monitoring instrumentation for currents and voltages (both steady state and transient).

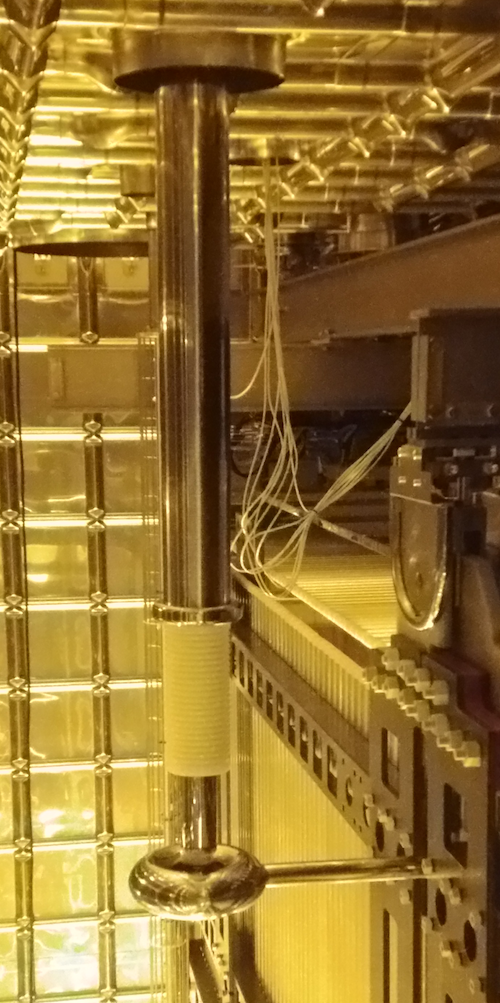

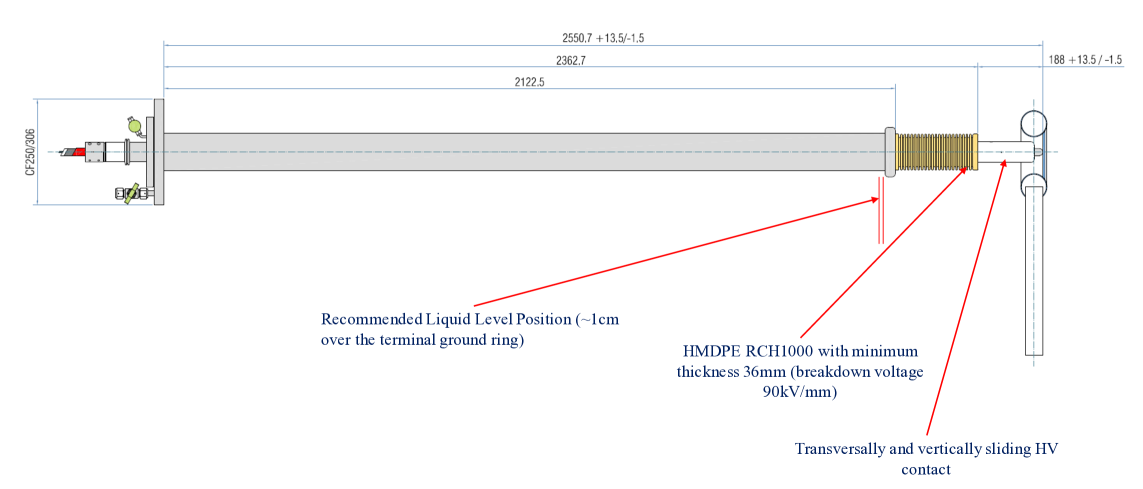

The 180 kV voltage necessary to produce the required electric field of 500 V/cm is delivered by the power supply through an RC filter and a HV feedthrough to the CPA. The design of the HV feedthrough is based on the reliable construction technique adopted for the ICARUS HV feedthrough [16] and shown in Figure 24. Before installation, the feedthrough was successfully operated for several days in a test stand at voltages up to 300 kV.

The feedthrough design has a coaxial geometry, with an inner conductor (HV) and an outer conductor (ground) insulated by UHMWPE, as illustrated in Figure 24. The outer conductor, a stainless-steel tube, surrounds the insulator, extending down through the cryostat into the LAr. In this geometry, the E field is confined within regions occupied by high-dielectric-strength media (UHMW PE and LAr). The inner conductor is made of a thin-walled stainless steel tube to minimise the heat input and to avoid the creation of argon gas bubbles around the lower end of the feedthrough. A contact, welded at the upper end for the connection to the HV cable, and a round-shaped elastic contact for the connection to the cathode, screwed at the lower end, completes the inner electrode. Special care has been taken in the assembly to ensure complete filling of the space between the inner and outer conductors with the (polyethylene) PE dielectric, and to guarantee leak-tightness at ultra-high vacuum levels.

Filter resistors are placed between the power supply and the feedthrough. Along with the cables, these resistors reduce the discharge impact by partitioning the stored energy in the system. The resistors and cables together also serve as a low-pass filter reducing the 30 kHz voltage ripple on the output of the power supply.

The filter resistors are of a cylindrical design. Each end of an HV resistor is electrically connected to a cable receptacle. A cylindrical insulator is placed around the resistor, and a grounded stainless steel tube surrounds the insulator.

The instrumentation in ProtoDUNE-SP provided useful information on HV stability. Outside the cryostat, the HV power supply and cable-mounted toroids monitor the HV. The power supply has capabilities down to tens of nA in current read-back and is able to sample the current and voltage every 300 ms. The cable-mounted toroid is sensitive to fast changes in current; the polarity of a toroid’s signal indicates the location of the current-drawing feature as either upstream or downstream of it.

Inside the cryostat, pick-off points near the anode monitor the current in each resistor chain. Additionally, the voltage of the ground planes (GPs) above and below each drift region can diagnose problems via a high-value resistor connecting the GP to the cryostat.

HV Commissioning, Beam Time Operation and Stability Runs

During cool-down and LAr filling, a power supply was used to supply 1 kV to the cathode and monitor the current draw of the system. As the system cooled from room temperature to LAr temperature, the resistance increased by 10%, consistent with expectations. Once the LAr level had exceeded the height of the top GP, the voltage was ramped up to the nominal voltage.

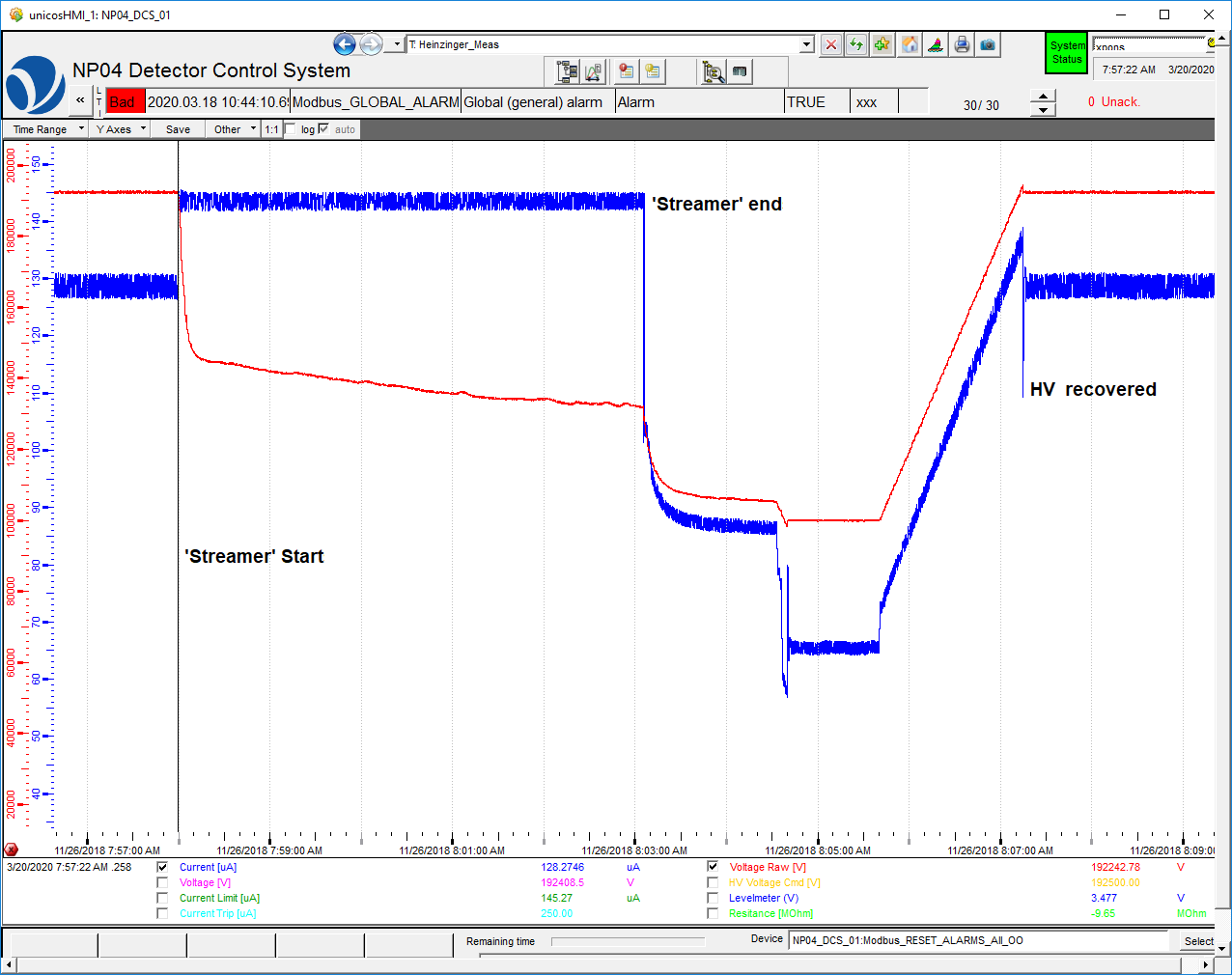

Two types of instabilities emerged in the cold side of the HV system. The first type was a so-called current blip, during which the system drew a small excessive current that persisted for no more than a few seconds. The magnitude of the excess current during current blips increased over the subsequent three weeks from 1% to 20%. The second type of instability, called a “current streamer,” exhibited persistent excessive current draw from the HV power supply with accompanying excessive current detected on a GP and on the beam plug. These two types of instabilities occurred periodically throughout the beam run. The frequency of both types increased over time after the system was powered on, until a steady state of about ten current blips/day and one current streamer every four hours was reached. These effects are consistent with a slow charging-up process of the insulating components of the FC supports, which then experience partial discharges that are recorded as HV instabilities. This process restarts after every long HV-off period.

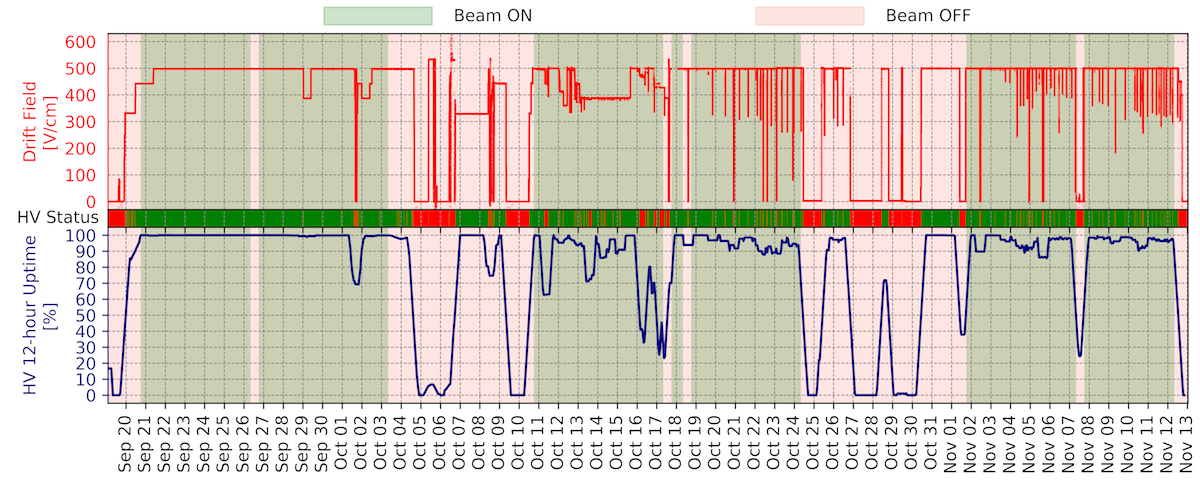

In addition, these processes seemed to be enhanced by the LAr bulk high purity, which allowed the electric current to develop. At low purity electronegative impurities acted as quenchers, blocking the development of the leakage current. During the 2018 beam run periods, priority was given to operating the ProtoDUNE-SP detector with maximal uptime in order to collect as much beam data as possible at the nominal HV conditions [17]. In some cases, mostly outside of the beam run period, the HV system was turned off momentarily to allow the HV system components to discharge. This is reflected as larger dips in the uptime plot shown in Figure 25 [18]. During periods when the rest of the subsystems (including the beam) were stable, the moving 12-hour HV uptime fluctuated between 96% and 98%. Automated controls to quench the current streamers were then successfully implemented in an auto-recovery mode. These helped to increase the uptime significantly, by optimising the ramping down and up of the HV power supply voltage, which was performed in less than four minutes. The process of the auto-recovery mode is shown in Figure 26.

Investigating the long-term behaviour of the HV instabilities and understanding their origin became goals of the long-term operation of ProtoDUNE-SP in 2019. As mentioned above, it appeared that the current-streamer effect is a charging-up process with its frequency increasing with time after a long HV-off period. This behaviour was observed repeatedly and this cause was confirmed in 2019. The current-streamer rate stabilised at 4-6 events per day, and the location remained on the same single ground plane (GP#6). The rate and location were approximately independent of the HV applied on the CPA in the 90 kV to 180 kV range.

More recently, after changing the LAr re-circulation pump in April 2019, the detector was operated for several months in very stable cryogenic conditions and with very high and stable LAr purity (as measured by purity monitors and cosmic rays). During this period, a significant evolution was observed. The HV system was set and operated at the nominal value of 180 kV at the CPA for several weeks without interruption.

To better understand the current-streamer phenomenon, the HV system was operated for about fifty days without the auto-recovery script, and the current streamers were left to evolve naturally. They typically lasted six to 12 hours, exhibiting steady current and voltage drawn from the HV power supply, and they eventually self-quenched without any intervention. During this period, the repetition rate was significantly reduced to about one current streamer every 10-14 days; this rate can be compared to the 4-6 per day in the previous periods with auto-recovery on.

The auto-recovery script was then re-enabled and the current-streamer rate stabilised at about one in every 20 hours; in addition, the intensity of the current streamer on the GP was reduced with respect to the previous periods. As in the previous runs, the current streamers always occurred on the same GP (GP#6) with a small leakage current on the beam plug hose, which is close to GP#6.

This behaviour is a further indication that the current streamers were, in fact, a slow discharge process of charged-up insulating materials present in the high-field region outside of the FC. The auto-recovery mode did not allow a full discharge, so the charging up was faster, and the streamer repetition rate was shorter.

The LAr purity loss experienced at the end of July 2019 was accompanied by the complete disappearance of any HV instabilities. They gradually reappeared when the electron lifetime exceeded 200 microseconds, and their intensity constantly increased as purity improved. This behaviour replicated that observed after the initial filling, and is consistent with what has been observed on other similar systems [19], thus supporting the hypothesis that the HV instabilities are enhanced by the absence of electronegative impurities in high-purity LAr.

The effects of the current streamers on the front-end electronic noise and the PD background rate were investigated. No effect of the current streamers on the FE electronics was observed. On the other hand, recent analysis of the data collected by the PDS during active current streamers has indicated a high single photon rate on the upper upstream part of the TPC. This is consistent with the activities recorded on GP#6, which is located exactly at this upper upstream area.

4.2 Inner Detector: Anode Plane Assemblies and Front-end Electronics

4.2.1 Anode Plane Assemblies (APA)

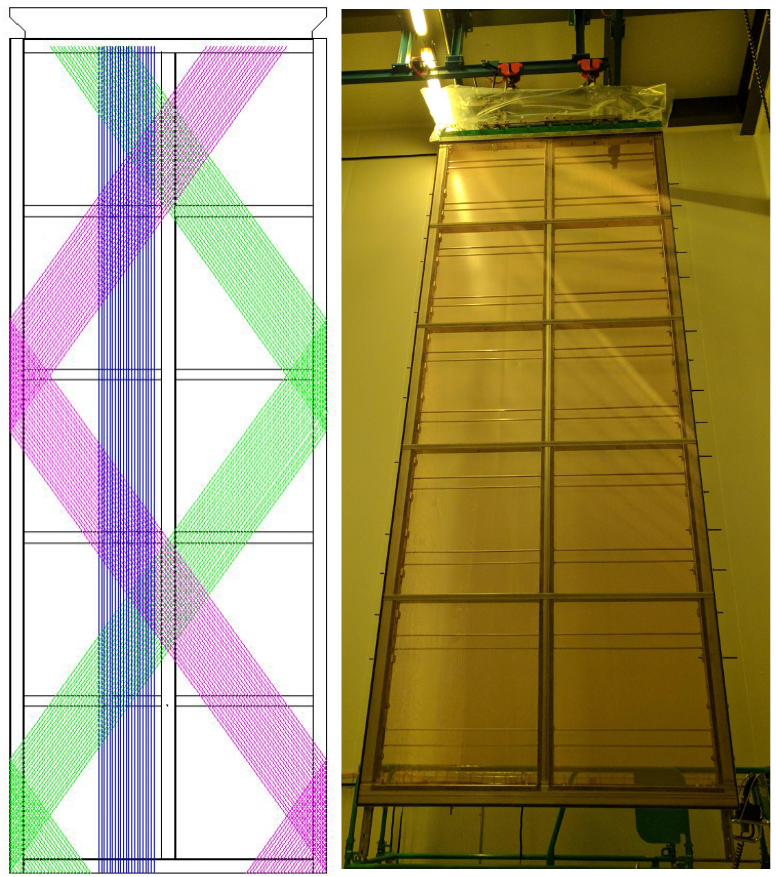

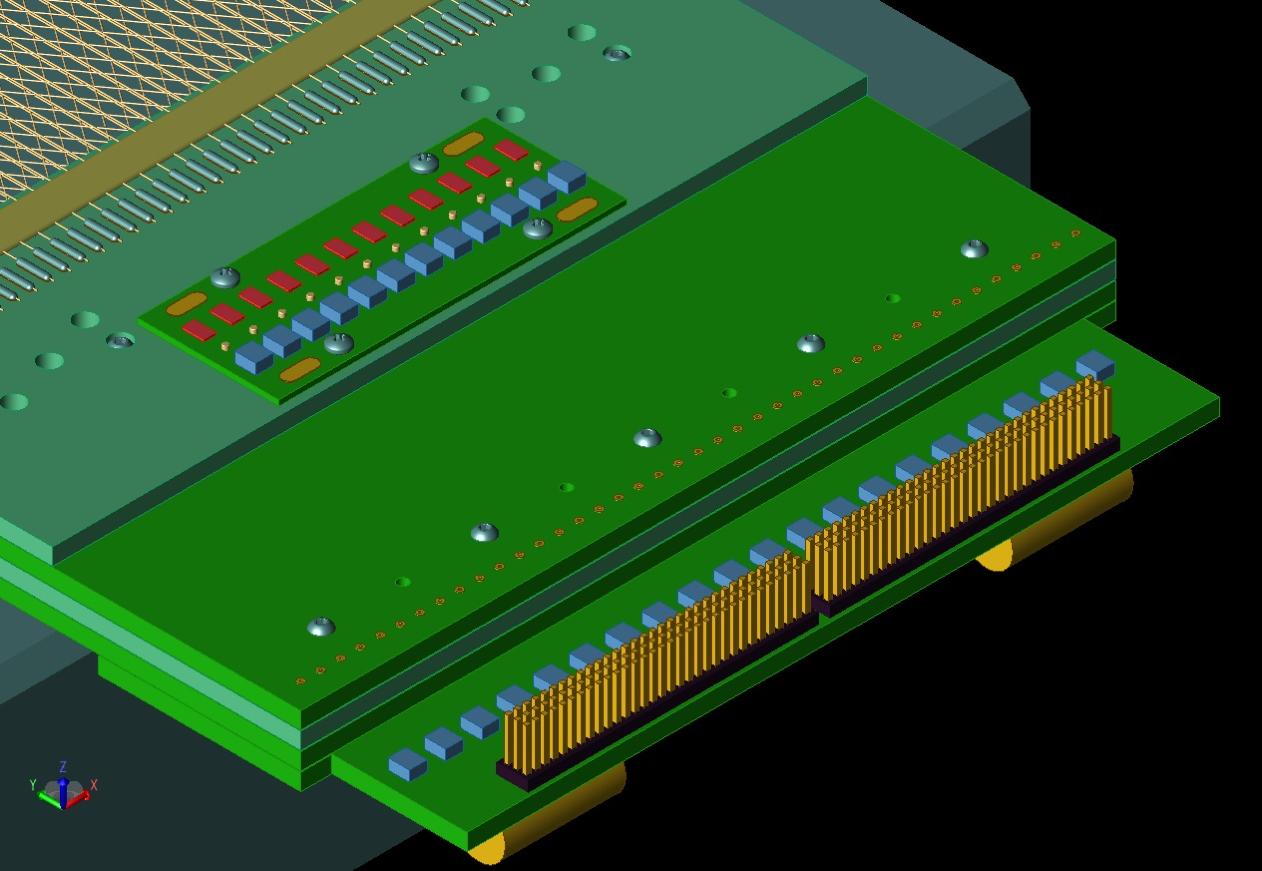

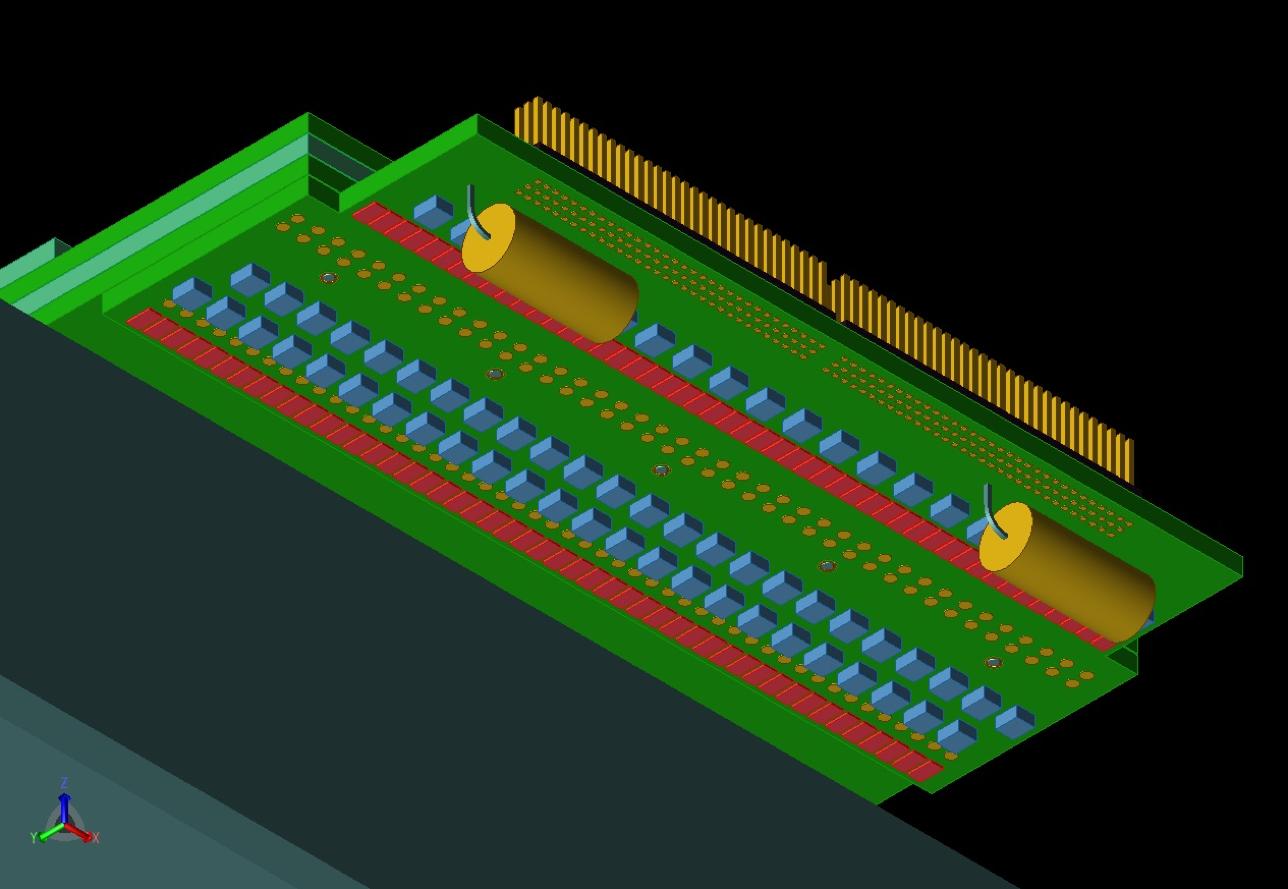

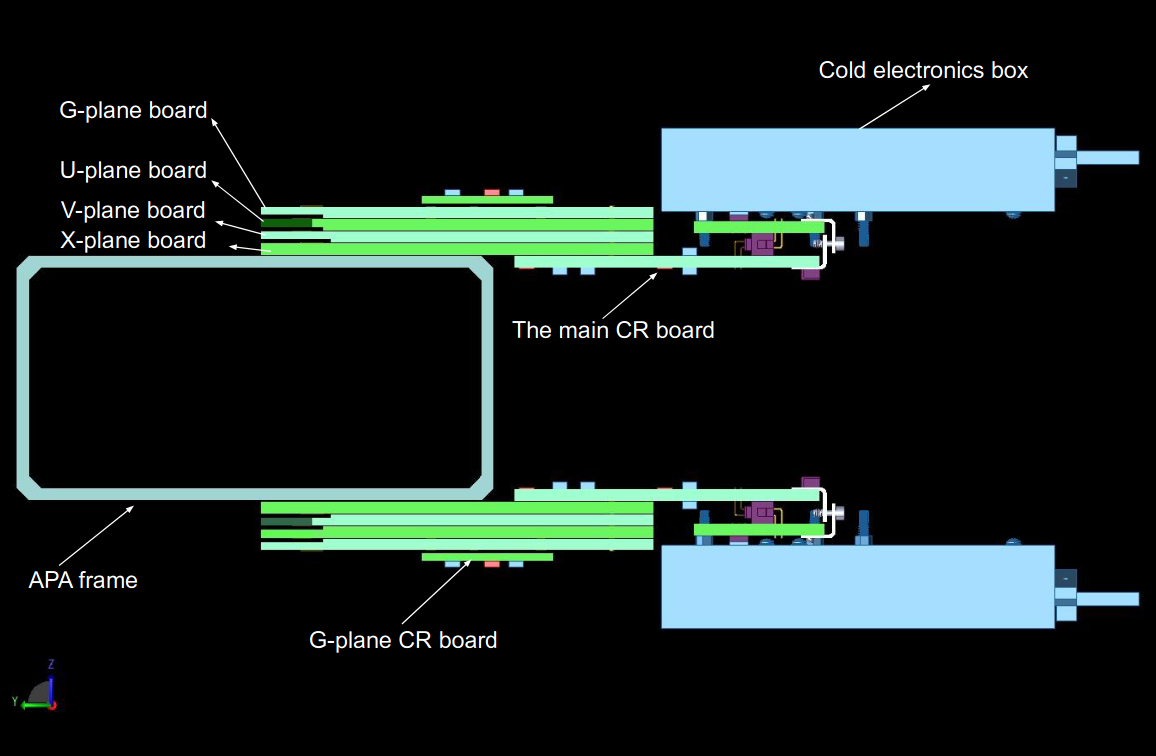

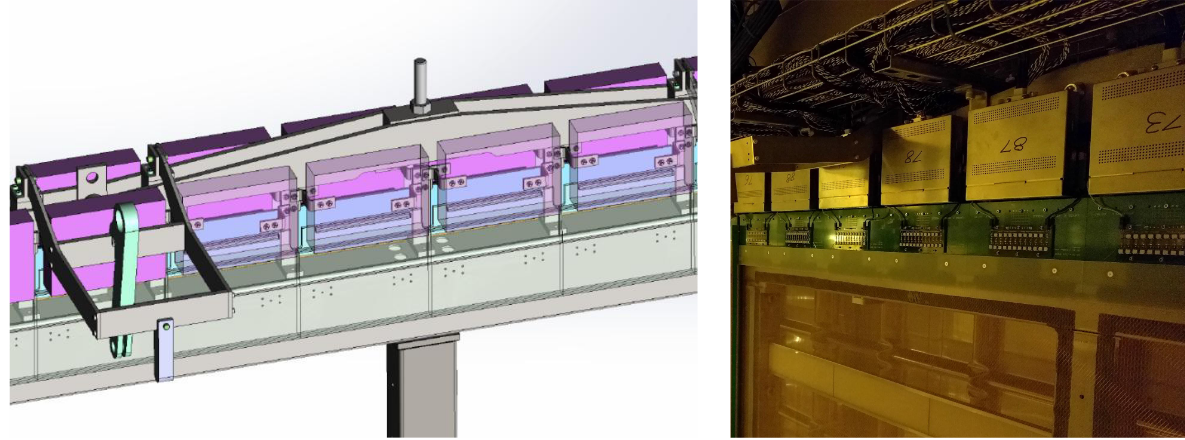

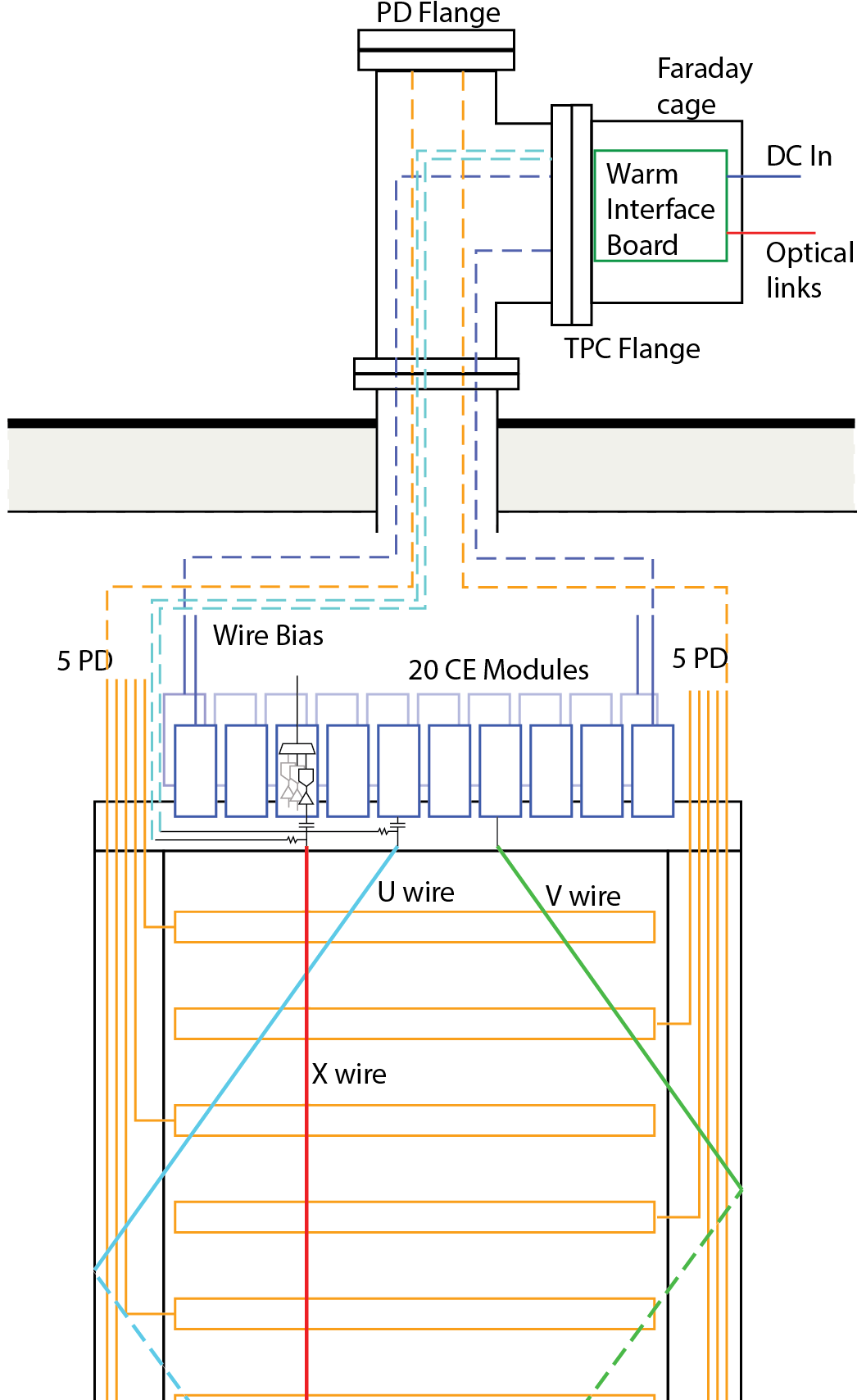

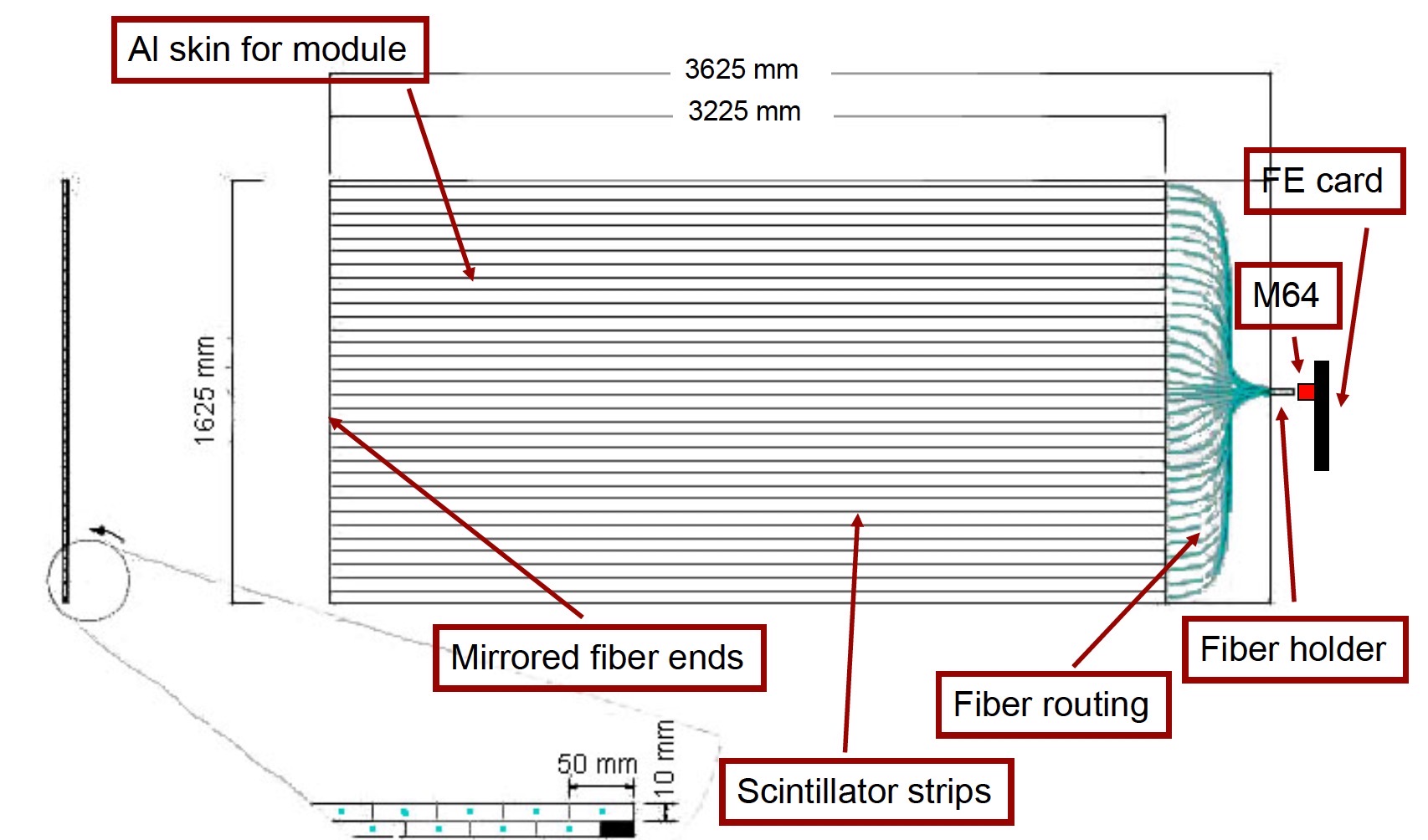

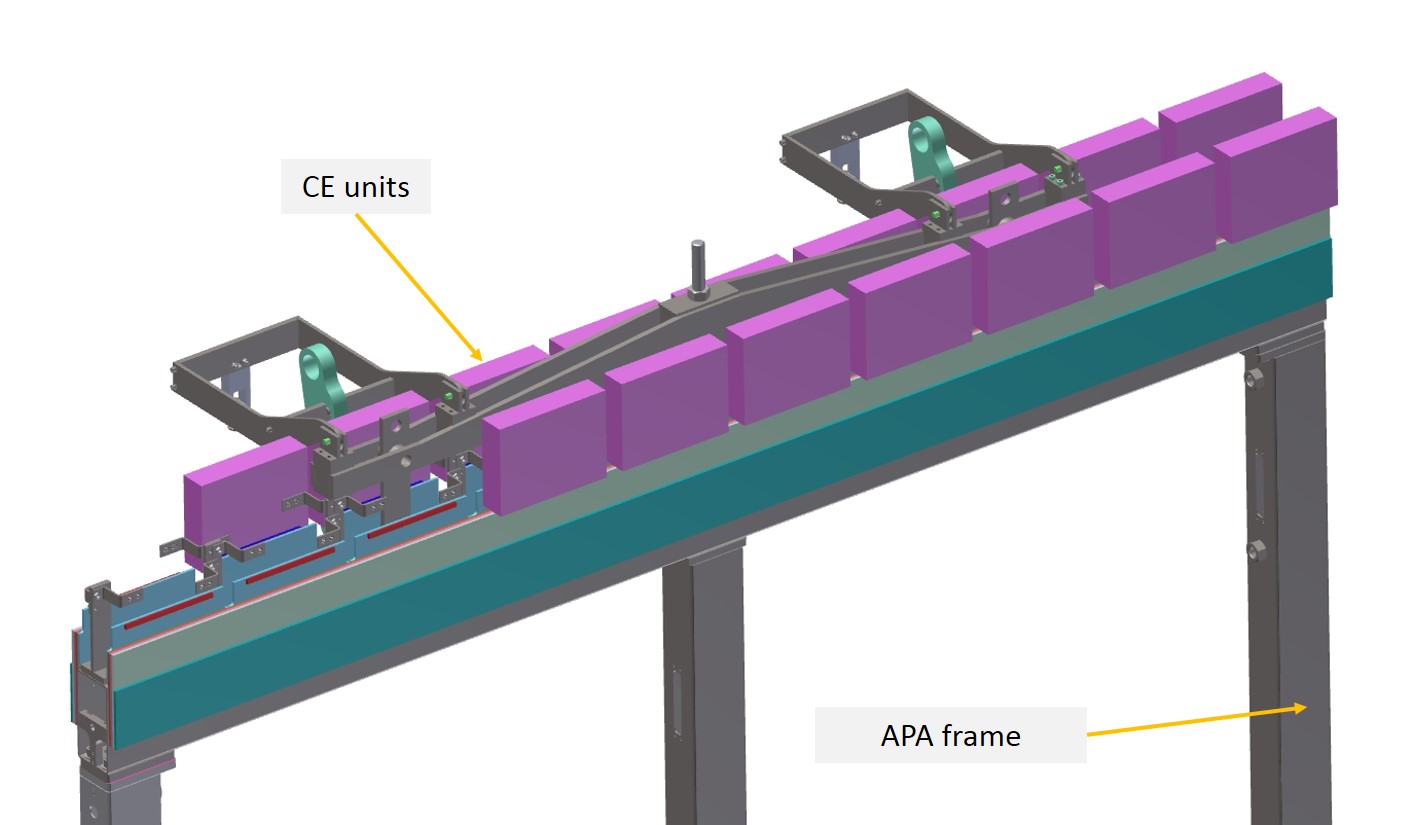

Anode Plane Assemblies (APAs) are the detector elements used to detect ionization electrons created by charged particles traversing the LAr volume inside the ProtoDUNE-SP TPC. There are two APA arrays, one on the outer side of each of the two drift volumes. Each array comprises three APAs (6.3 m tall, 2.3 m wide, 0.12 m thick) hung vertically and adjacent to each other. Each APA has layers of sense and shielding wires wrapped around a framework of lightweight, rectangular stainless steel tubing, as shown in Figure 27. The sense wire readout is performed by cold electronics (CE) attached at the upper end (head) of each APA.

The APAs are designed and built to address the physics performance specifications listed in Table 3, which are defined to ensure high-efficiency event reconstruction throughout the entire active volume of the LArTPC.

| Specifications | Value |

|---|---|

| MIP identification | 100% efficiency |

| Charge reconstruction | > 90% efficiency for > 100 MeV |

| Vertex resolution (, , ) | 1.5 cm, 1.5 cm, 1.5 cm |

| Particle identification | |

| Muon momentum resolution | < 18% for non-contained, < 5% for contained |

| Muon angular resolution | < 1∘ |

| Stopping hadron energy resolution | 1-5% |

| Shower identification | |

| Electron efficiency | > 90% |

| Photon mis-identification | < 1% |

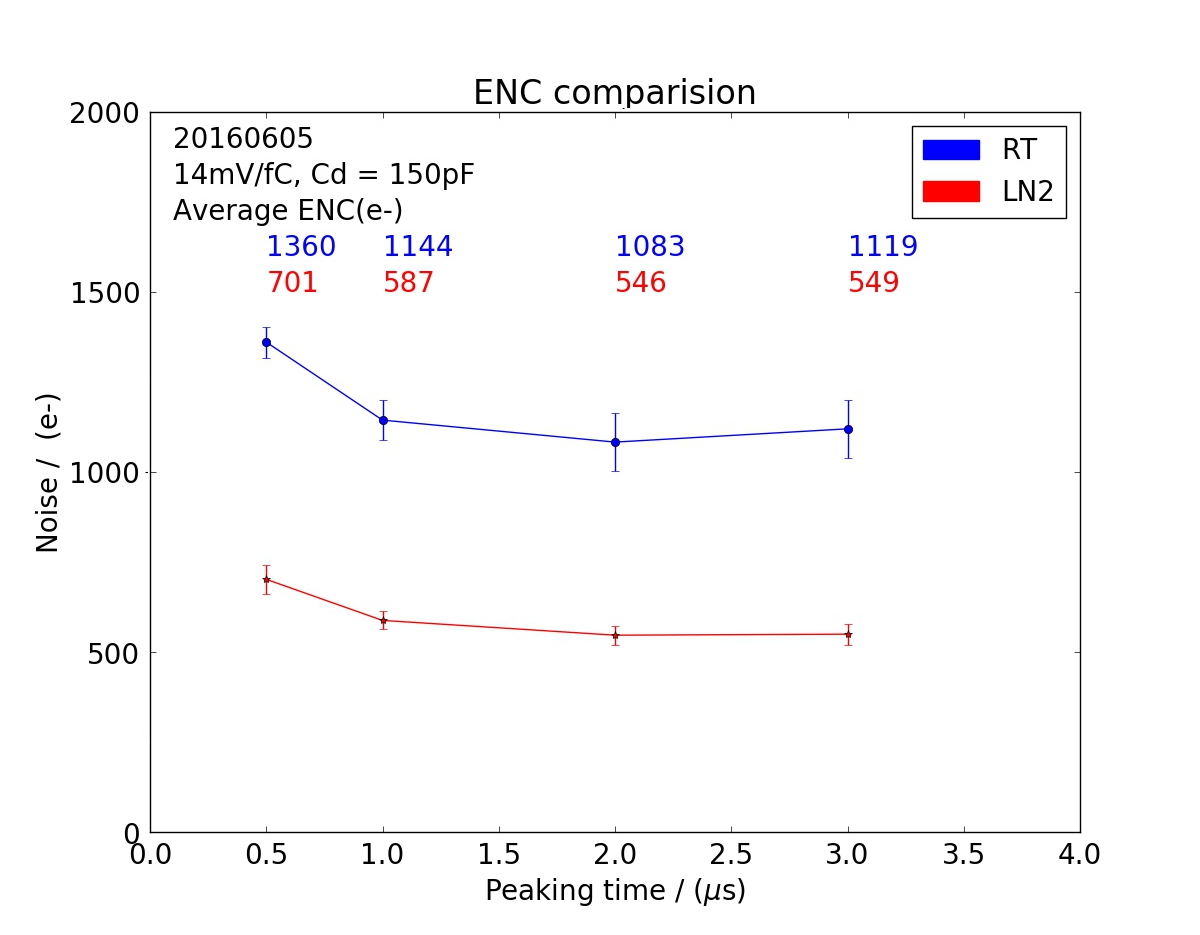

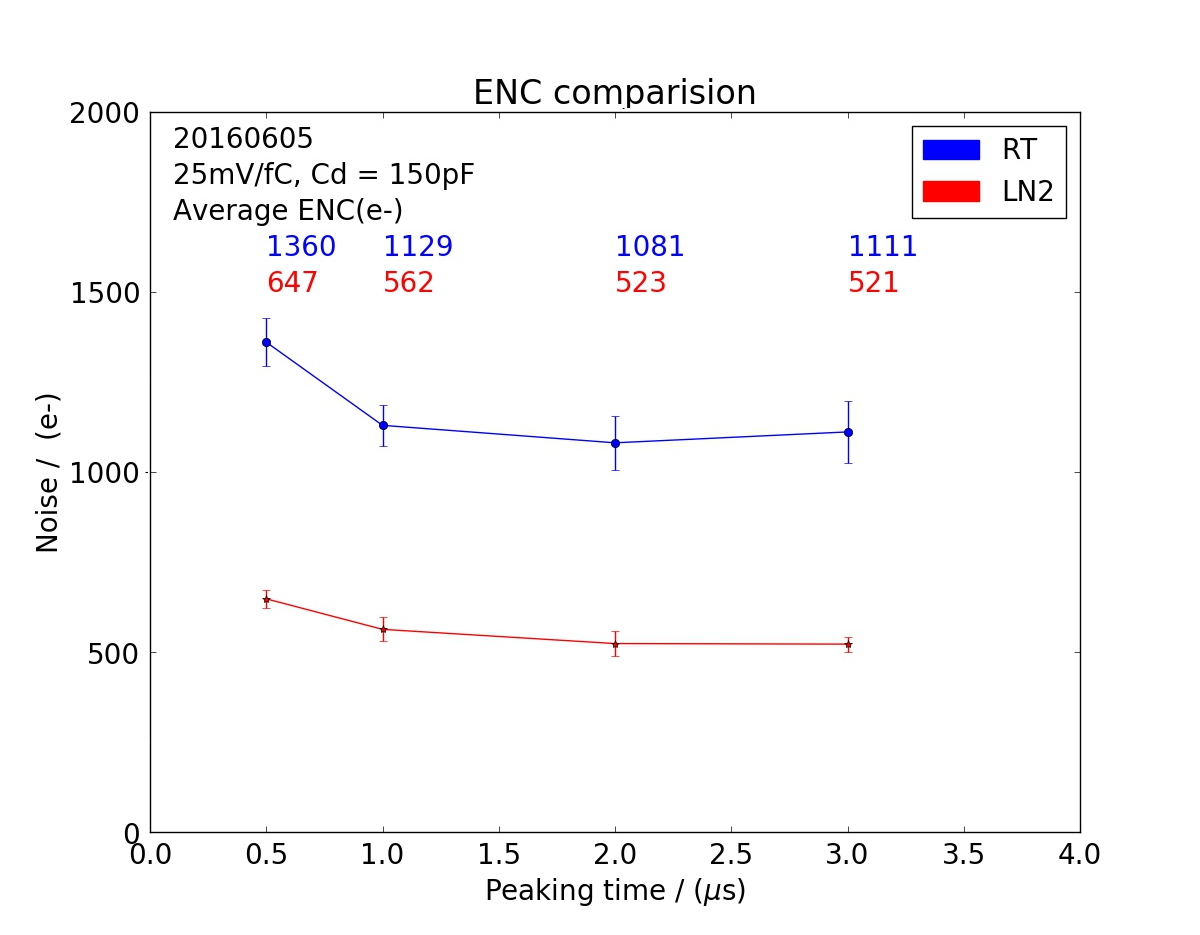

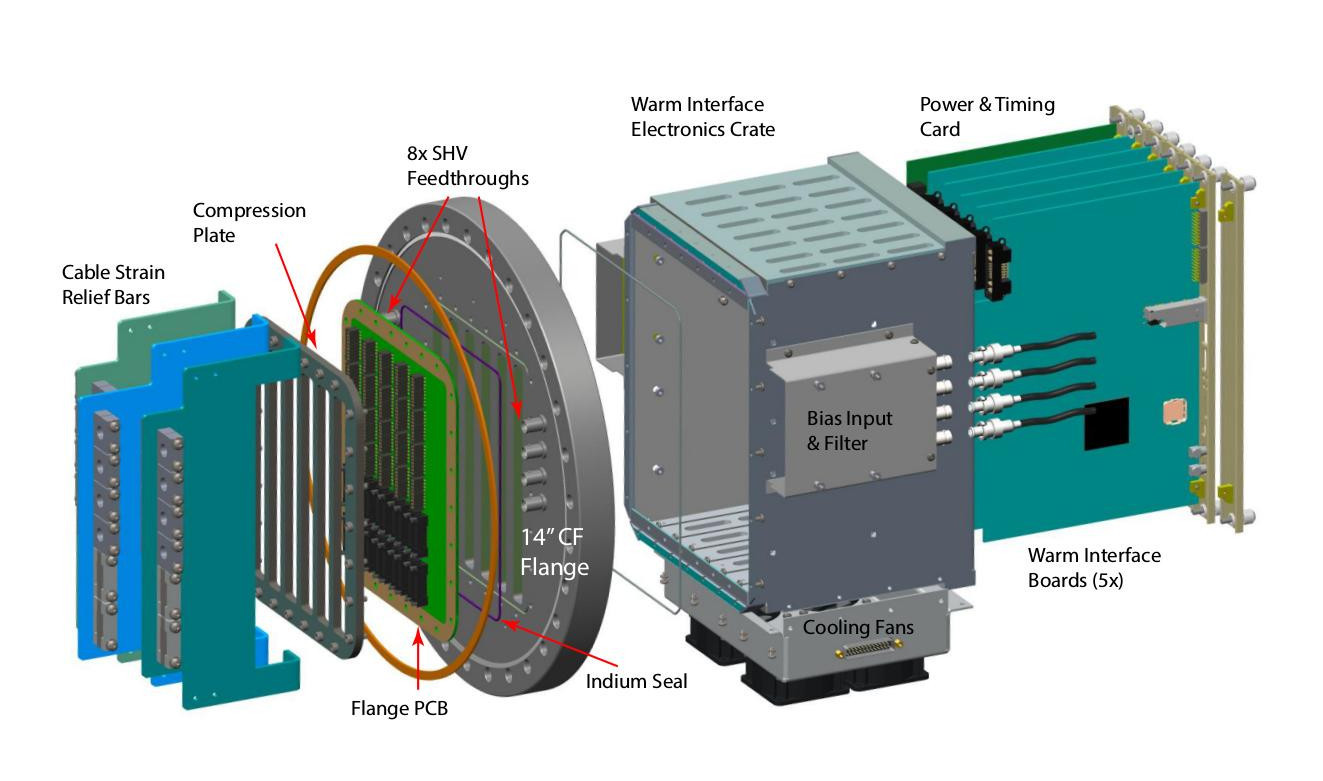

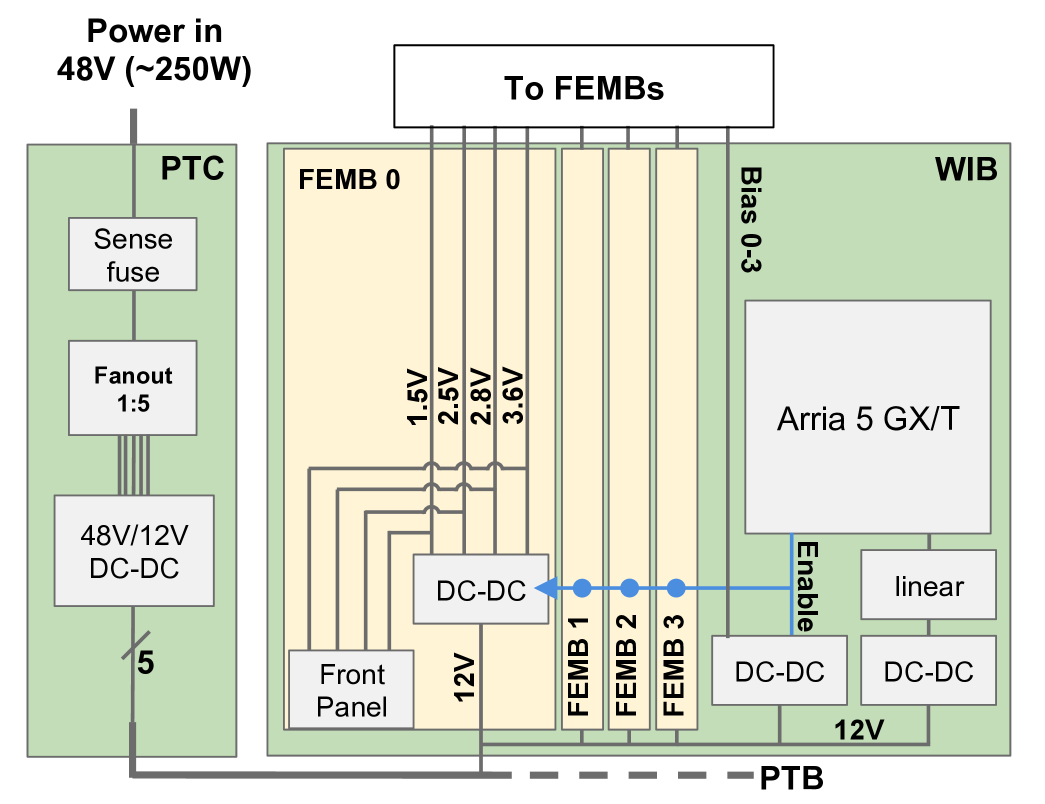

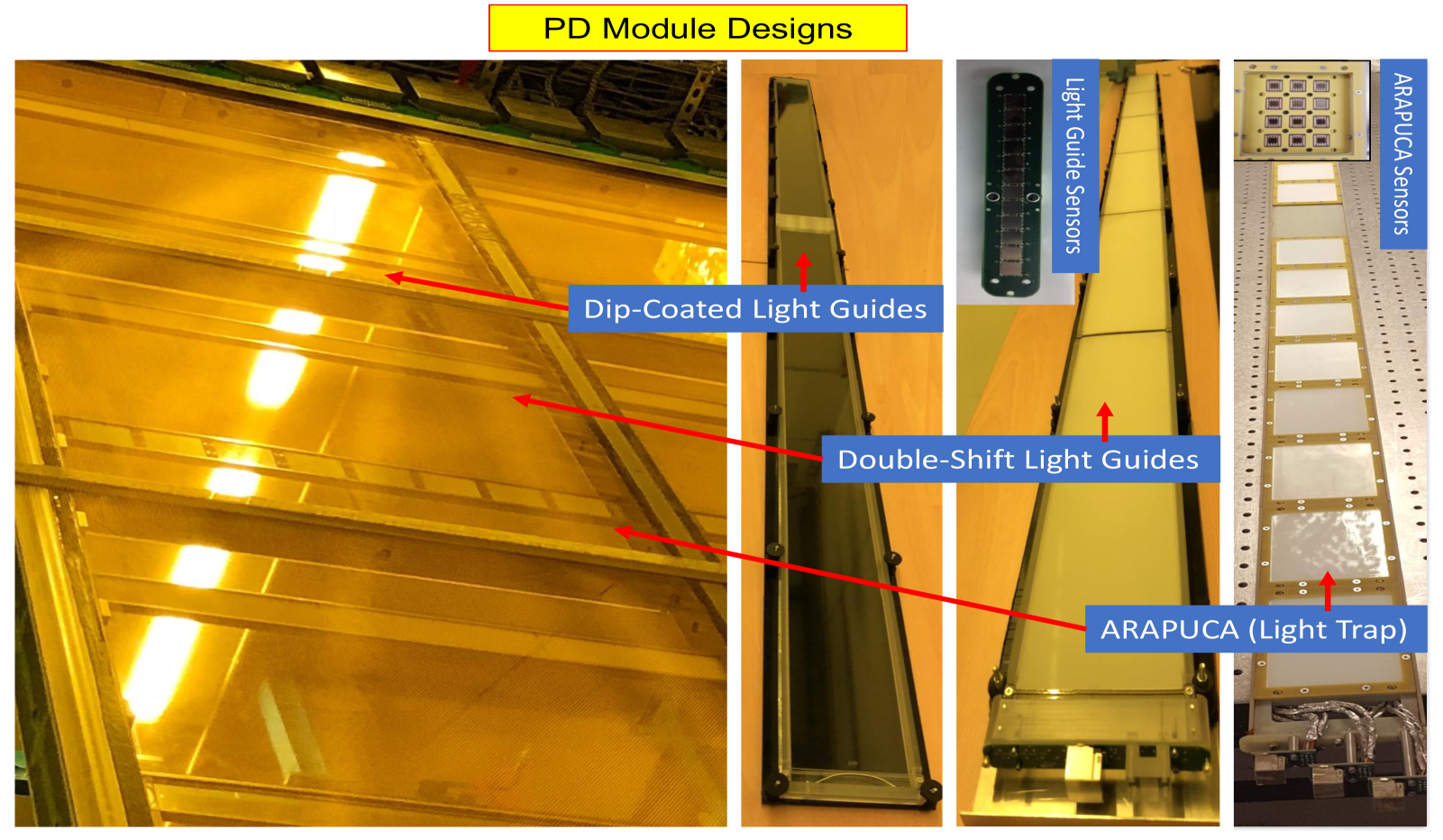

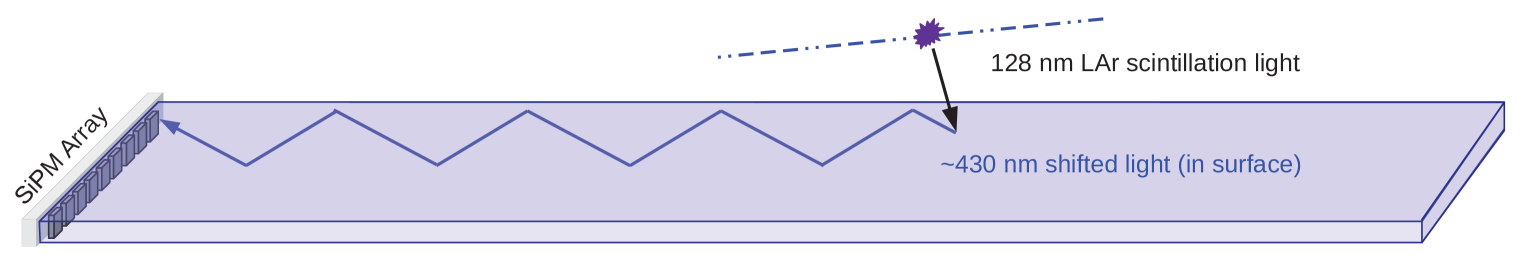

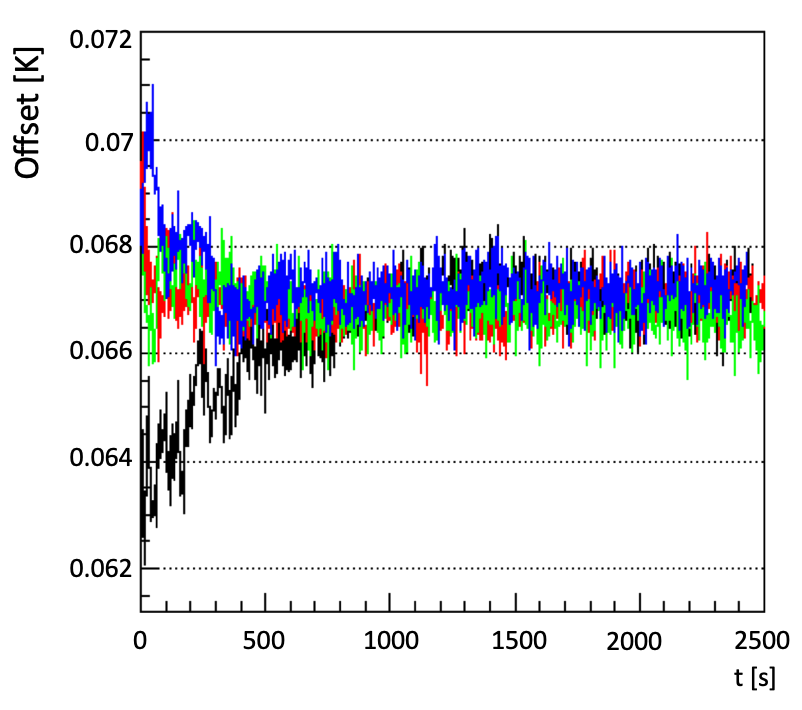

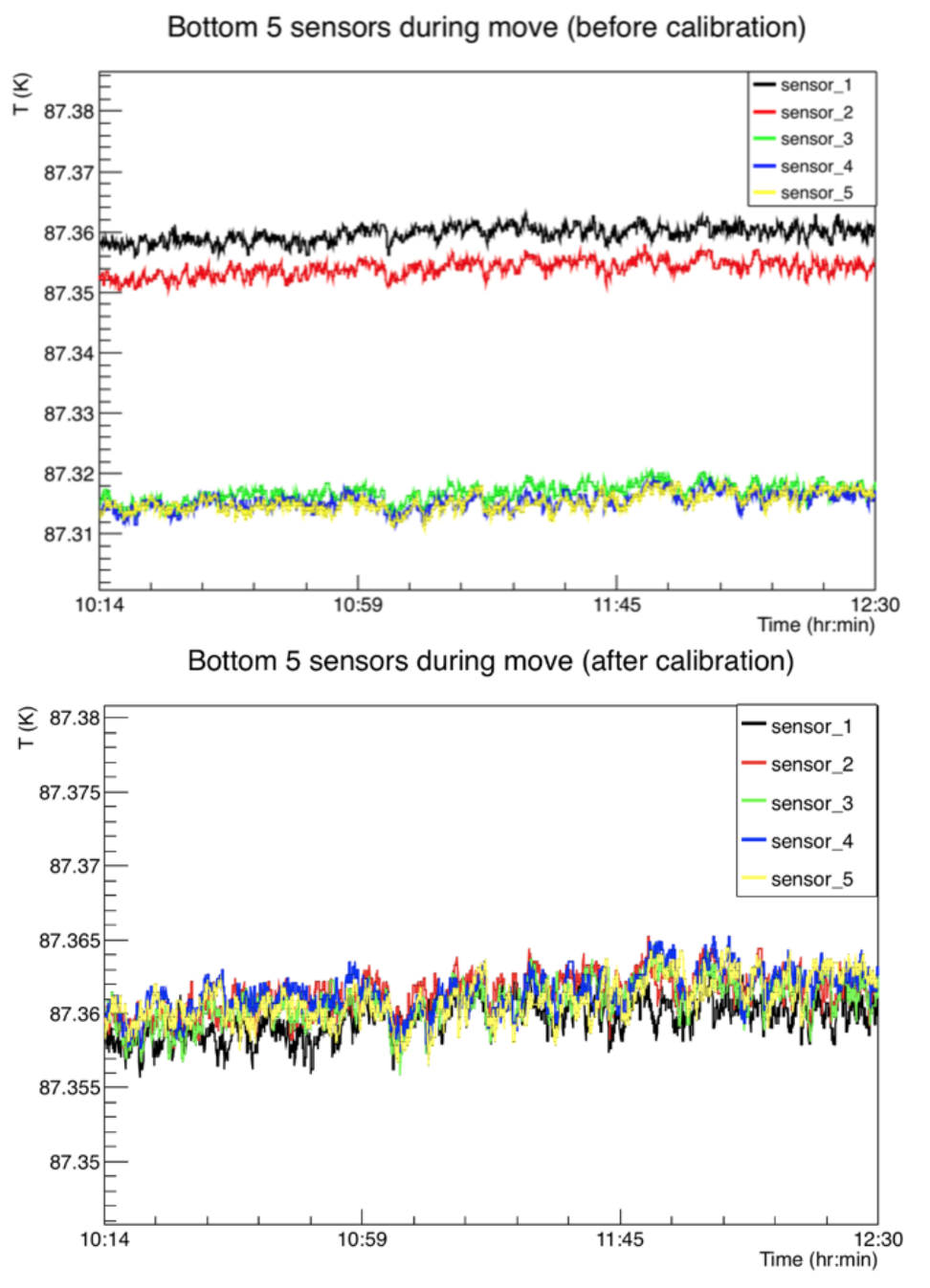

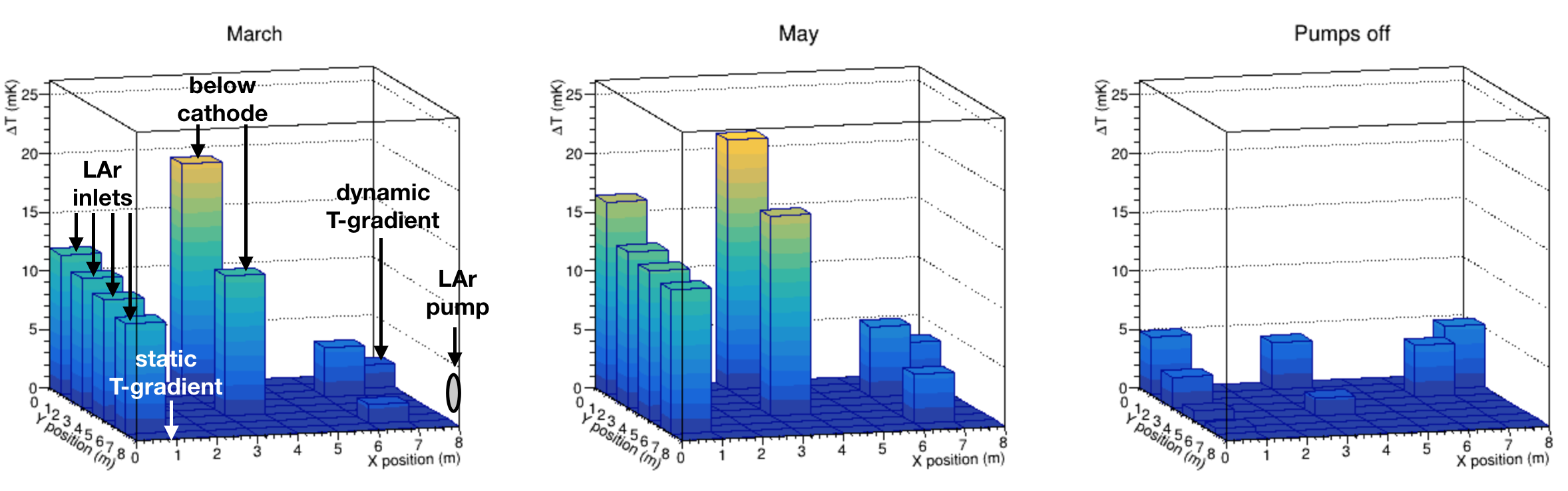

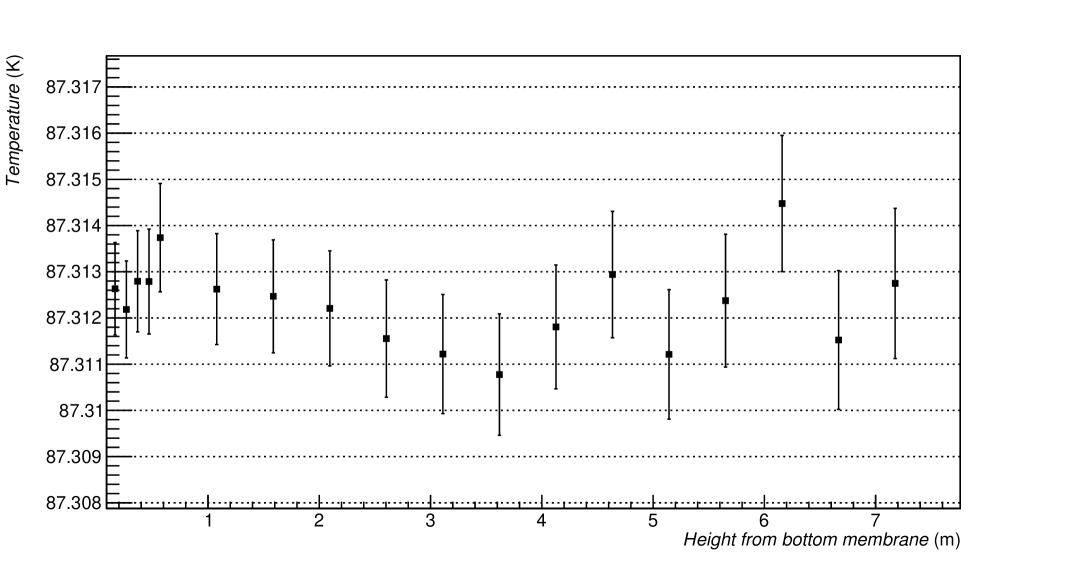

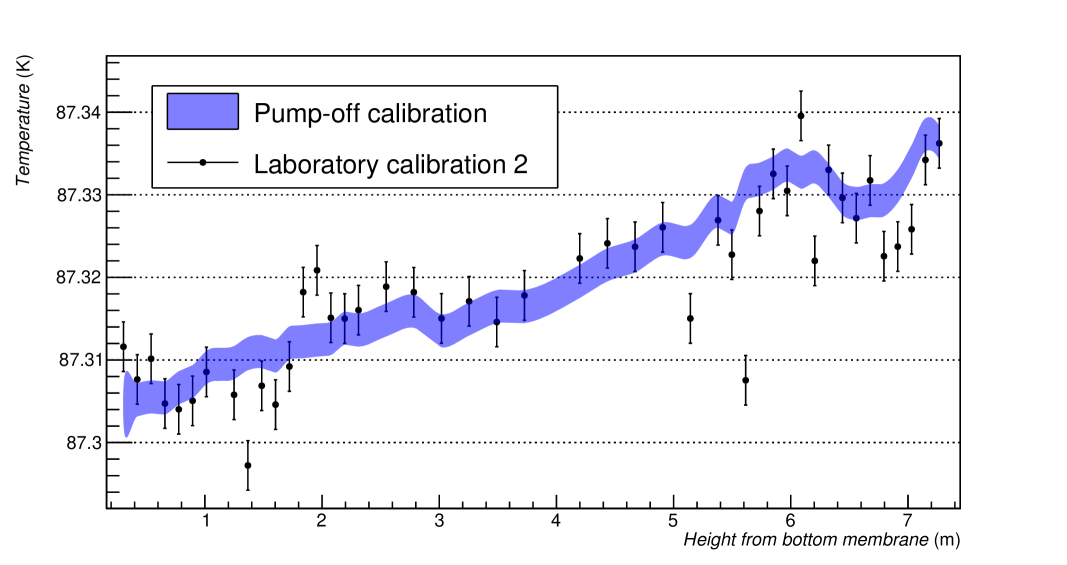

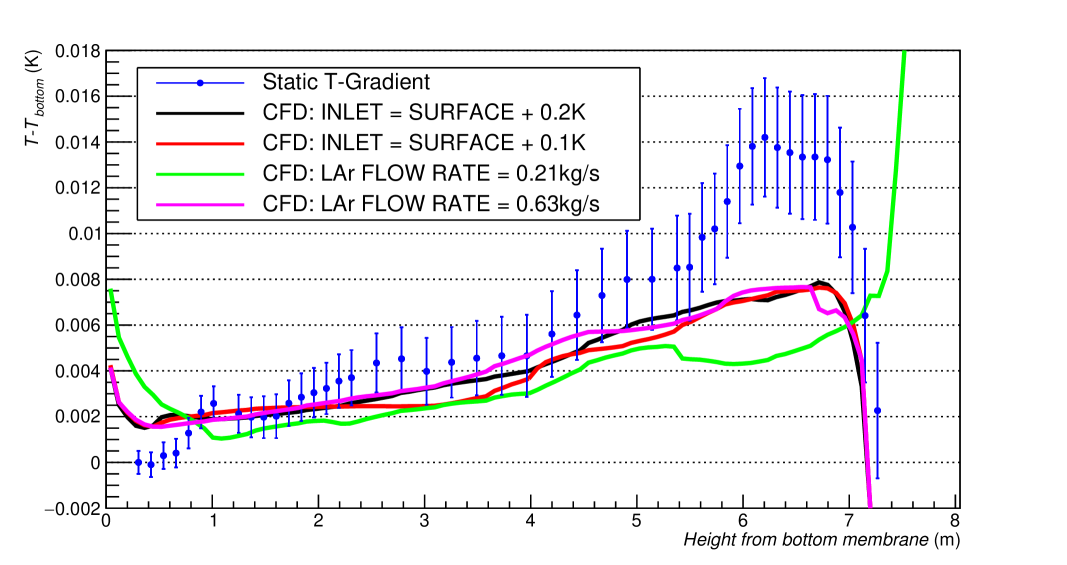

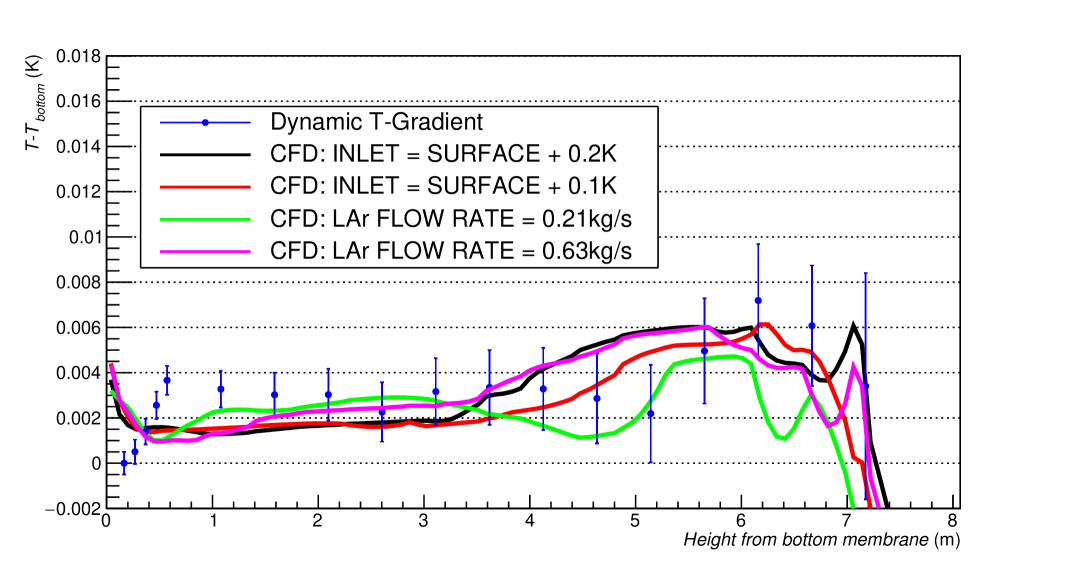

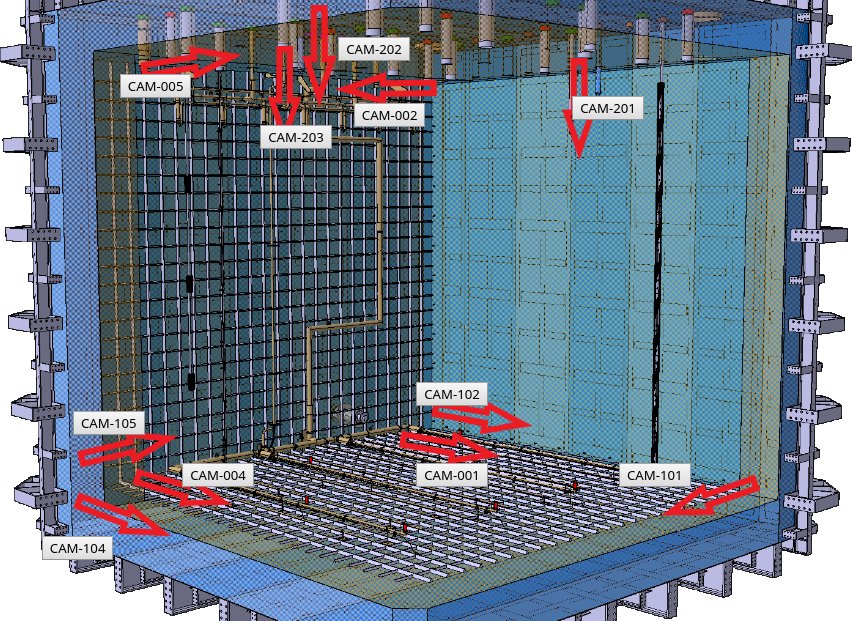

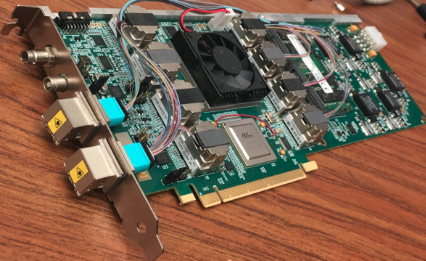

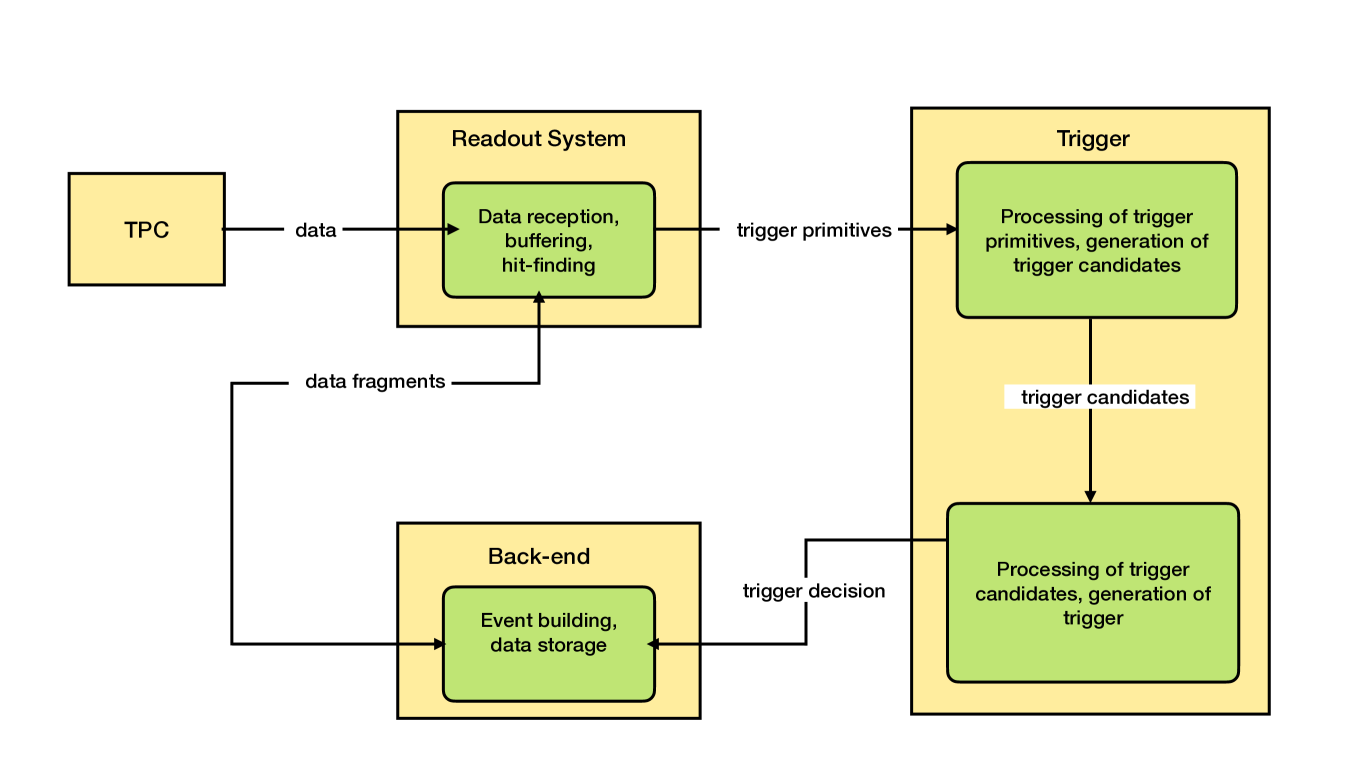

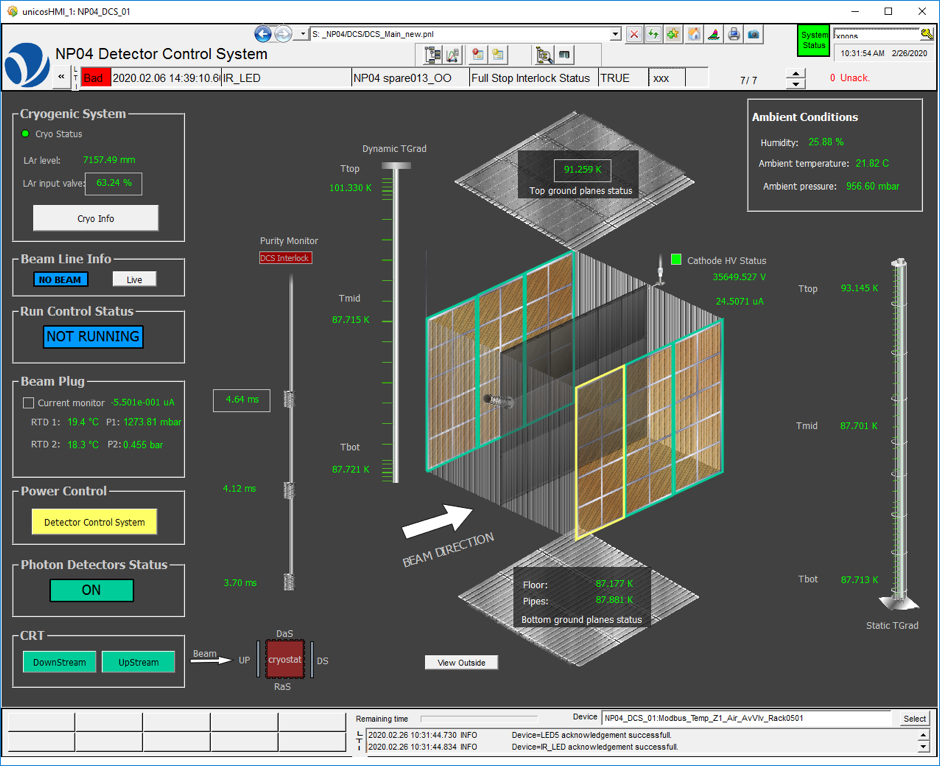

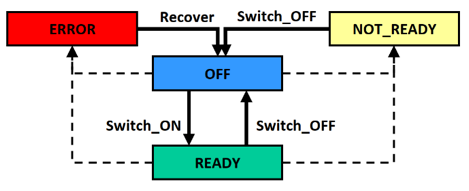

| Electron angular resolution | < 1∘ |