Float, borosilicate and tellurites as cover glasses in Si photovoltaics: optical properties and performances under sunlight

Abstract

One of the most significant materials in a solar panel is the glass, which provides transparency, UV protection as well as mechanical and chemical resistance. In this work, we describe the production of prototypes of four solar modules made using borosilicate, zinc-tellurite, Pr3+ doped zinc-tellurite, and float glass as cover materials. The performance of these prototypes was evaluated under a solar simulator, and a device was developed to monitor all prototypes under real conditions. A comparison between indoor and outdoor measurements shows that outdoor results are fundamental to evaluate the performance of modified solar modules as the ones considered in this study. In addition, we demonstrate the fundamental role played by the refractive index of cover glasses in the performance of the prototypes, and discuss how this feature could be explored to achieve enhanced devices, as well as other benefits that may arise from this field of research.

In the 1950s two breakthroughs made today’s mainstream solar energy technology possible: Silicon solar cells [1] and the float glass method to produce flat glasses [2]. Before that time, high-quality flat glass was produced by the metal plate manufacturing process. Due to the need of grinding and polishing, this method wasted about 20% of the glass mass. It demanded high capital and operating costs, which motivated the development of the float glass process, where a ribbon of glass floats on the surface of a molten tin bath while continuously moving and cooling. This process produces highly homogeneous flat glasses, making grinding and polishing unnecessary. The technology was ready to dominate the market at the end of that decade, after about 7 years under development at the Pilkington industries [2]. A modern floating line produces flat glass at speeds of 4000 m2/h and coatings can be cheaply deposited inline by chemical vapor deposition (CVD) at fast rates [3] (100 nm/s), providing for example anti-reflective or self-cleaning capabilities [4]. Silicon photovoltaics are profiting from float glass transparency, mechanical quality, chemical resistance, and UV protection, which are fundamental to produce panels that achieve a lifespan of several decades.

Silicon photovoltaics (PV) constituted 95% of the photovoltaic market in 2020, which corresponds to about 200 GWp in annual production capacity [5]. The power per area in such devices is W/m2, and roughly 1 billion m2 of solar panels are produced every year. Even though it seems impressive, our needs are orders of magnitude beyond this number, which imposes many challenges towards the tera-watt deployment of PV [6]. One of them is the expansion of production of float glass [7]. The thickness of the cover glass in most of the PV on the market today is above 3 mm, and bi-facial PV [8] growth is expected to increase [5] and speed up the flat glass demand. Pilkington’s method was decisive to enable this massive deployment of solar energy, and glasses may contribute even further to tackle the climate crisis.

About 80 million tonnes of solar panels are going to reach their end-of-life (EOL) in the next 30 years [9]. Glasses account for more than 50% of this total weight [10], and glass science may contribute to reducing this amount of EOL products. There is a demand to reduce the thickness [11] (and weight) of cover glasses in PV’s, as well as to attenuate their degradation [12], which consequently would expand PV’s lifespan even further. This would also reduce the demand for metals, which has been pointed out as a constraint to PV expansion and sustainability [13, 14, 15, 16, 17]. Although the cover glass may seem one of the simplest components of a PV panel, several complex features are demanded of a material to be viable in practical applications. Besides high transparency, chemical, mechanical, and UV resistance [11], other properties include coatability [18], which is fundamental to reduce reflection losses in the glass/air interface and may even be explored to provide self-cleaning capabilities to the surface [19].

During the last decade, a significant effort has been made to develop spectral converters (SC), which could be built-in the cover glass or deposited as a thin film over or below it, to improve the spectral mismatch between sunlight radiation and Si solar cells spectral sensitivity. SC’s provide by this way a mechanism to expand the efficiency limit of PVs beyond the Shockley-Queisser limit [20]. This can be achieved by processes such as downconversion (DC) [21, 22, 23] or upconversion [24, 25]. The downshifting (DF) of photons, a phenomenon that can be classified as a subcategory of DC [23], consists in the conversion of high energy photons into low energy photons, with a quantum efficiency lower than 1. Pr3+ doped materials, for instance, offer one of the simplest ways to achieve DF, due to the well-known emission lines of this ion around 600 nm, 650 nm and 1050 nm under blue light excitation [26]. Yet interesting scientific findings have been reported on several SC materials, most of them are unfeasible at the needed scale [27, 28, 23, 29, 30]. In this way, some authors have investigated small variations in the composition of the float glass [11], which should not interfere in the production process and would be readily available at the industry level.

Several works have demonstrated high quantum efficiencies of tellurite glasses, a glass family that we have been investigating in the last few years [26, 31, 32], and could potentially be used as SCs [33, 34]. A few prototypes made with glasses of this family were already investigated [35] and, to the best of our knowledge, they were not evaluated under sunlight or compared to other prototypes made with commercially available glasses, which is the goal of this work. Here we report on the evaluation of tellurite glasses as cover materials of PV prototypes, where they are directly compared to similar prototypes made with two commercially available glasses. To accomplish this comparative study, we also developed an affordable tool to monitor the power output of several prototypes simultaneously, which was used to evaluate their performances under real sunlight. The following glasses were selected for this investigation: low iron float glass; borofloat 33; the TZNL (73.3%Te-19.6%Zn-4.9%Na-2.2%La [32]) and Praseodymium doped (0.1%Pr6O11) TZNL glasses. Some key properties of these samples are shown in Table 1.

| Glass | (g/cm3) | 111Linear refractive index at 633 nm | Thickness (mm) | k (Wm-1K-1) | (J kg-1K-1) | D (m2s-1) | K |

|---|---|---|---|---|---|---|---|

| Float glass222Data from Saint-Gobain | 2.5 | 1.52 | 4.0 | 1.06 | 800 | 5.3 | 9 |

| Borosilicate 3.3333Data from Schott | 2.23 | 1.47 | 1.54 | 1.2 | 830 | 6.8 | 3.3 |

| TZNL | 5.34 | 1.98 (Ref. 37) | 4.2 | 1.1 (Ref. 38) | 801 | 2.6 | 11.8 |

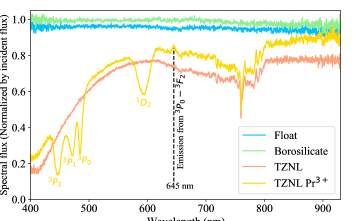

A calibrated fiber-coupled spectrometer (LaserLine LSP-2) was used to measure the incident and transmitted spectral flux through the glass sample, under sunlight illumination. The results are shown in Fig. 1, where the high quality of the thinner borosilicate sample is evidenced. In the Pr3+ doped TZNL sample we could detect four ground state absorption bands from this dopant and an enhanced overall transmission of light. This may happen due to a small decrease in the refractive index and possibly due to reactions induced by the dopant [32]. A small band at 645 nm was also detected, and attributed to the 3P0-3F2 decay of Pr3+ ions. This result confirms that we have archived DF, still the ion is much more effective in absorbing than emitting photons.

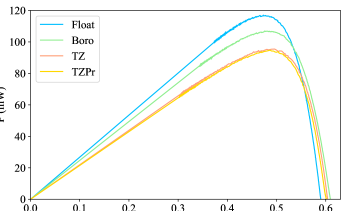

The glasses were used to build prototypes. Four identical AR coated p-type Si solar cells (2.0x3.9 cm) were encapsulated at 85°C using ethylene-vinyl acetate (EVA) as the encapsulant and Tedlar-Pet-Tedlar (TPT) as the backsheet. The obtained prototypes were named Float, Boro, TZ, and TZPr, referring to the glass used in each one. A solar simulator (ScienceTech SS2.5kW) was used to measure IxV curves under standard conditions (AM1.5G spectrum, 1000 W/m2 and cell temperature at 25°C), which were used to obtain the power as shown in Fig. 2.

The power achieved by TZ and TZPr was 95 mW, while Boro and Float have reached peaks of 106 mW and 116 mW, respectively. It is important to consider that the ASTM standard for solar simulators [39] is designed to compare silicon cells or modules under indoor testing. An AM1.5G spectrum in a class AAA simulator should reproduce the solar irradiance within a margin of 25% in six bands of the spectrum (five 100 nm wide and the last one between 900-1100 nm). For optical spectroscopy, a solar simulator does not necessarily reproduce the solar spectrum. Also, other glass properties may affect the performance of the prototypes, and to properly evaluate them it is critical to measure their performances under real conditions, simultaneously. We developed a system to perform such measurements, which is described next.

From the data in Fig. 2, the circuit load to achieve peak power of 2 Ohms is obtained. Precision resistors (1 Ohm each) were used to obtain this load and Hall sensors (WCS2702) were used to measure the currents. A multimeter HP 34401a was used to obtain the sensitivity of the current sensors ( mV/mA) and to measure the total load in each prototype ( Ohm). Voltages were measured directly by the built-in analog-to-digital converter of a microcontroller (STM32103C8T6, resolution 0.8056 mV/level), which averaged current and voltage values over 192 measurements that took about 5 milliseconds each. The averaged values were sent to a computer via serial communication.

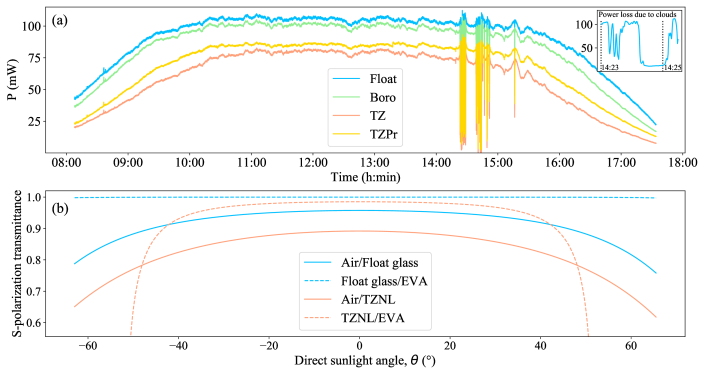

The cells have to be cleaned and soldered to tinned copper wires before the encapsulation, where the components are heated at 85°C and slightly pressured. In the construction of the prototypes, all the steps may potentially introduce problems. In order to evaluate our ability to reproduce all these steps, as well as the reliability of our measurement system, several prototypes were produced using float glass as cover. The power of four of these prototypes was simultaneously measured under sunlight illumination, and the results were consistent inside a margin error lower than 3%. Damaged prototypes were intentionally evaluated and the power drop observed was very high if the silicon cell was cracked (50-90%), and measurable (10%) if air bubbles remained in the EVA below the cover glass. Figure 3 (a) shows data obtained in a measurement performed on February 5 (2021, location -26.228°,-52.670°). The plane of the prototypes was set to be perpendicular to the sun around noon. The sunrise/sunset time was 06:09/19:21, which resulted in an angular change of about 0.2272°/min during 792 minutes on that day. The inset in this figure highlights the power loss due to clouds, which lowered momentarily the prototype temperatures. As a result, all devices reached their peak power on that day just after 14:25. To interpret the data, the Fresnel transmittance of several surfaces in the prototypes was analyzed. Fig. 3 (b) shows the S-polarization transmittance for all prototypes.

The high refractive index of the TZNL glass introduces a significant loss to the TZ and TZPr prototypes by the total internal reflection between TZNL and the EVA (). Consequently, for direct sunlight angle higher than 50o, TZ and TZPr prototypes allow only diffuse light to reach the silicon cell. Thus, under this condition, TZ and TZPr achieved only half of the power produced by the Float glass prototype. The Fresnel transmittance is shown in Fig. 3 (b) highlighting the inflection point around the critical angle. In previous work, we have already discussed the challenges to use a high refractive index material as cover in a solar panel [31], and the results shown here confirm that. When the incident angle is low the performance of the prototypes remains dictated by the reflection losses, which are quite high in the TZNL matrix due to its high refractive index.

To achieve the total electrical energy produced by each device during the experiment, the power presented in Fig. 3 (a) was integrated for each prototype. A summary of the electrical output data obtained is shown in Table 2.

| P/A (W/m2) | E (J) | Ps/A (W/m2) | |

|---|---|---|---|

| Float | 143 (100%) | 3058 (100%) | 148 (100%) |

| Boro | 137 (95%) | 2826 (92%) | 135 (86%) |

| TZ | 110 (76%) | 2005 (65%) | 121 (82%) |

| TZPr | 117 (82%) | 2288 (74%) | 121 (82%) |

Float, boro, TZ and TZPr prototypes produced 3058, 2826, 2005, and 2288 Joules, respectively. As one can see, the TZ delivered only 65% of the total power delivered by the Float, which is significantly lower than the 82% observed under the solar simulator. This reduction in total energy is due to reflection losses in the TZNL/EVA interface, as we can see in Fig. 3 (b). While the s-polarization transmittance is near 1.0 for the Float/EVA interface during the entire day, transmittance at the TZNL/EVA interface is dramatically lower in the morning (before 10:00) and the afternoon (after 15:30). As a result, the power ratio between TZPr/Float increases from 53% at the beginning of the measurement to 80% around 10:00, which is just 2% lower than what was achieved in the indoor testing. Such difference could be a result of different equilibrium temperatures in each module, once parameters such as thermal diffusivity and thickness should affect the heat dissipation, and consequently the silicon temperature and the performance of the devices. Such thermal investigation will be considered in future work.

The results shown here demonstrate the importance to investigate these cover glasses and the prototypes made with them under sunlight. The power measurement under the solar simulator is an important indicator of the prototype power in a real situation, though, as we have seen, the total energy produced may be significantly different. In our case, we could explain such differences mostly due to the s-polarization transmittance, as seen in Fig. 3, and even though the TZPr prototype performed better than the TZ, our results do not indicate that Pr3+ and the DF related to it are playing an important role. On the other hand, the introduction of this dopant made the glass slightly more transparent, mainly in the infrared region where Si solar cells are more sensitive.

Glasses certainly may play a role to boost silicon solar cells. Nonetheless, if we aim to develop a practical solution to this challenge we cannot focus on spectral modifications only. For example, even if we could obtain a high quantum efficiency spectral converter based on a high refractive index material, such as the TZNL glass, it would be necessary to reduce reflection losses. This should require the use of a high refractive index polymer [40], for instance, which is likely to be unfeasible at the photovoltaic industry level. Besides that, several other requirements were not evaluated for the TZNL glass, such as its chemical or thermal strengthening, and the resulting mechanical resistance. TZNL is also an expensive glass, based in Tellurium oxide, which is a quite rare commodity [41] and the mass production of this glass may not be feasible. However, in some specific applications, even expensive SC may be economically viable, as in concentrated photovoltaics [42], where sunlight is concentrated several hundred times in a small solar cell, and cover glass can be used.

Some authors have even discussed the rare-earth cost to produce a SC [43], but such values are meaningless if we are not accounting for the host and the process in which such SC would be produced and added to the silicon module. Allsopp et al. [11] have analyzed the performance of PV’s prototypes made with several glass compositions quite similar to the float glass (doped versions). However, only solar simulator measurements were performed. As we have discussed, even a class AAA solar simulator does not exactly reproduce the sunlight spectrum, which could be important in order to evaluate a SC. As showed here, evaluating performances under real sunlight was possible using our homemade measurement system, and it could provide important and complementary information for PV characterization.

Pilkington describes in detail the challenges to develop the float process. In his words [2]: “The principles of the process perhaps sound very simple,…How complex the development work was is illustrated by the fact that it took us seven years and four million pounds to make any saleable glass and a total of seven million pounds before the process could achieve the set objective of replacing plate”. Such an effort and industrial success of the float process were not achieved by chance, and after 50 years nothing more suitable to produce massive amounts of high-quality flat glass was discovered.

In this context, the Pilkington method will continue to be fundamental for the tera-watt deployment of solar energy, still we could think of a modified glass to be produced by the same process. The method has already been used to fabricate other glasses, such as borosilicates [44] and aluminosilicates [45, 46], which are required in specific applications. Silicon solar cells are reaching a “practical Schockley-Queisser limit” [28, 47], and the projections made by industry [5] do not indicate any prospect that another technology will replace Si PVs. However, to achieve and sustain a multi tera-watt scale PV plant worldwide, the materials and processes involved should become more sustainable and cheaper.

To the best of our knowledge, researchers have not yet explored the possibility of a low refractive index and low melting temperature glass. To produce 1 ton of float glass, about 5.5 GJ of energy is needed [48], and a reduced melting temperature would result in energy savings as well as lower emissions of greenhouse gases. If such material could achieve the chemical and mechanical resistance required for a cover glass in PVs, such devices would benefit from lower reflection losses in the air/glass interface that could be helpful at low incidence angles of light. SCs are an interesting technology, but at the industry level, we are restricted to use the float glass or the CVD process to obtain SCs. In future work, we will pursue different pathways to expand these possibilities.

Acknowledgements.

The authors acknowledge the support from the Brazilian agencies CAPES, CNPq, Fundação Araucária and FINEP. Companhia Paranaense de Energia (COPEL) and Agência Nacional de Energia Elétrica (Aneel) are also acknowledged for the financial support through the contract P&D 2866-0466/2017.Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

References

- Pearson [1957] G. L. Pearson, Conversion of Solar to Electrical Energy, American Journal of Physics 25, 591 (1957).

- Pilkington [1969] L. A. B. Pilkington, Review Lecture: The float glass process, Proceedings of the Royal Society of London. A. Mathematical and Physical Sciences 314, 1 (1969).

- McCurdy [1999] R. J. McCurdy, Successful implementation methods of atmospheric CVD on a glass manufacturing line, Thin Solid Films 351, 66 (1999).

- Sarkın et al. [2020] A. S. Sarkın, N. Ekren, and Ş. Sağlam, A review of anti-reflection and self-cleaning coatings on photovoltaic panels, Solar Energy 199, 63 (2020).

- ITRPV [2019] ITRPV, International Technology Roadmap for Photovoltaic, Itrpv , 76 (2019).

- Haegel et al. [2019] N. M. Haegel, H. Atwater, T. Barnes, C. Breyer, A. Burrell, Y.-M. Chiang, S. De Wolf, B. Dimmler, D. Feldman, S. Glunz, J. C. Goldschmidt, D. Hochschild, R. Inzunza, I. Kaizuka, B. Kroposki, S. Kurtz, S. Leu, R. Margolis, K. Matsubara, A. Metz, W. K. Metzger, M. Morjaria, S. Niki, S. Nowak, I. M. Peters, S. Philipps, T. Reindl, A. Richter, D. Rose, K. Sakurai, R. Schlatmann, M. Shikano, W. Sinke, R. Sinton, B. Stanbery, M. Topic, W. Tumas, Y. Ueda, J. van de Lagemaat, P. Verlinden, M. Vetter, E. Warren, M. Werner, M. Yamaguchi, and A. W. Bett, Terawatt-scale photovoltaics: Transform global energy, Science 364, 836 (2019).

- Burrows and Fthenakis [2015] K. Burrows and V. Fthenakis, Glass needs for a growing photovoltaics industry, Solar Energy Materials and Solar Cells 132, 455 (2015).

- Kopecek and Libal [2018] R. Kopecek and J. Libal, Towards large-scale deployment of bifacial photovoltaics, Nature Energy 3, 443 (2018).

- Heath et al. [2020] G. A. Heath, T. J. Silverman, M. Kempe, M. Deceglie, D. Ravikumar, T. Remo, H. Cui, P. Sinha, C. Libby, S. Shaw, K. Komoto, K. Wambach, E. Butler, T. Barnes, and A. Wade, Research and development priorities for silicon photovoltaic module recycling to support a circular economy, Nature Energy 10.1038/s41560-020-0645-2 (2020).

- Xu et al. [2018] Y. Xu, J. Li, Q. Tan, A. L. Peters, and C. Yang, Global status of recycling waste solar panels: A review, Waste Management 75, 450 (2018).

- Allsopp et al. [2020] B. L. Allsopp, R. Orman, S. R. Johnson, I. Baistow, G. Sanderson, P. Sundberg, C. Stålhandske, L. Grund, A. Andersson, J. Booth, P. A. Bingham, and S. Karlsson, Towards improved cover glasses for photovoltaic devices, Progress in Photovoltaics: Research and Applications 28, 1187 (2020).

- Katayama et al. [2019] N. Katayama, S. Osawa, S. Matsumoto, T. Nakano, and M. Sugiyama, Degradation and fault diagnosis of photovoltaic cells using impedance spectroscopy, Solar Energy Materials and Solar Cells 194, 130 (2019).

- Graedel et al. [2015a] T. E. Graedel, E. M. Harper, N. T. Nassar, P. Nuss, B. K. Reck, and B. L. Turner, Criticality of metals and metalloids, Proceedings of the National Academy of Sciences of the United States of America 112, 4257 (2015a).

- Graedel et al. [2015b] T. E. Graedel, E. M. Harper, N. T. Nassar, and B. K. Reck, On the materials basis of modern society, Proceedings of the National Academy of Sciences of the United States of America 112, 6295 (2015b).

- Månberger and Stenqvist [2018] A. Månberger and B. Stenqvist, Global metal flows in the renewable energy transition: Exploring the effects of substitutes, technological mix and development, Energy Policy 119, 226 (2018).

- Li and Adachi [2019] W. Li and T. Adachi, Evaluation of long-term silver supply shortage for c-Si PV under different technological scenarios, Natural Resource Modeling 32, 1 (2019).

- Ren et al. [2021] K. Ren, X. Tang, and M. Höök, Evaluating metal constraints for photovoltaics: Perspectives from China’s PV development, Applied Energy 282, 10.1016/j.apenergy.2020.116148 (2021).

- Deubener et al. [2009] J. Deubener, G. Helsch, A. Moiseev, and H. Bornhöft, Glasses for solar energy conversion systems, Journal of the European Ceramic Society 29, 1203 (2009).

- de Jesus et al. [2015] M. A. M. L. de Jesus, J. T. d. S. Neto, G. Timò, P. R. P. Paiva, M. S. S. Dantas, and A. d. M. Ferreira, Superhydrophilic self-cleaning surfaces based on TiO2 and TiO2/SiO2 composite films for photovoltaic module cover glass, Applied Adhesion Science 3, 5 (2015).

- Markvart [2021] T. Markvart, Ideal solar cell efficiencies, Nature Photonics 15, 163 (2021), arXiv:1911.09662 .

- Liu et al. [2009] X. Liu, S. Ye, Y. Qiao, G. Dong, B. Zhu, D. Chen, G. Lakshminarayana, and J. Qiu, Cooperative downconversion and near-infrared luminescence of Tb 3+-Yb3+ codoped lanthanum borogermanate glasses, Applied Physics B: Lasers and Optics 96, 51 (2009).

- Leonard et al. [2013] R. L. Leonard, S. K. Gray, S. D. Albritton, L. N. Brothers, R. M. Cross, A. N. Eastes, H. Y. Hah, H. S. James, J. E. King, S. R. Mishra, and J. A. Johnson, Rare earth doped downshifting glass ceramics for photovoltaic applications, Journal of Non-Crystalline Solids 366, 1 (2013).

- de la Mora et al. [2017] M. de la Mora, O. Amelines-Sarria, B. Monroy, C. Hernández-Pérez, and J. Lugo, Materials for downconversion in solar cells: Perspectives and challenges, Solar Energy Materials and Solar Cells 165, 59 (2017).

- Goldschmidt and Fischer [2015] J. C. Goldschmidt and S. Fischer, Upconversion for Photovoltaics - a Review of Materials, Devices and Concepts for Performance Enhancement, Advanced Optical Materials 3, 510 (2015).

- Fischer et al. [2018] S. Fischer, A. Ivaturi, P. Jakob, K. W. Krämer, R. Martin-rodriguez, A. Meijerink, B. Richards, and J. Christoph, Upconversion solar cell measurements under real sunlight, Optical Materials 84, 389 (2018).

- Belançon et al. [2014] M. P. Belançon, J. D. Marconi, M. F. Ando, and L. C. Barbosa, Near-IR emission in Pr3+single doped and tunable near-IR emission in Pr3+/Yb3+codoped tellurite tungstate glasses for broadband optical amplifiers, Optical Materials 10.1016/j.optmat.2014.01.014 (2014).

- Huang et al. [2013] X. Huang, S. Han, W. Huang, and X. Liu, Enhancing solar cell efficiency: the search for luminescent materials as spectral converters, Chemical Society Reviews 42, 173 (2013).

- McKenna and Evans [2017] B. McKenna and R. C. Evans, Towards Efficient Spectral Converters through Materials Design for Luminescent Solar Devices, Advanced Materials 29, 1 (2017).

- Bubli et al. [2020] I. Bubli, S. Ali, M. Ali, K. Hayat, Y. Iqbal, S. Zulfiqar, and E. Cattaruzza, Enhancement of solar cell efficiency via luminescent downshifting by an optimized coverglass, Ceramics International 46, 2110 (2020).

- Ferreira et al. [2020] R. A. Ferreira, S. F. Correia, A. Monguzzi, X. Liu, and F. Meinardi, Spectral converters for photovoltaics – What’s ahead, Materials Today 33, 105 (2020).

- Taniguchi et al. [2019] M. M. Taniguchi, V. S. Zanuto, P. N. Portes, L. C. Malacarne, N. G. C. Astrath, J. D. Marconi, and M. P. Belançon, Glass engineering to enhance Si solar cells: A case study of Pr3+-Yb3+ codoped tellurite-tungstate as spectral converter, Journal of Non-Crystalline Solids 526, 119717 (2019).

- Taniguchi et al. [2020] M. M. Taniguchi, E. da Silva, M. A. T. da Silva, L. S. Herculano, R. F. Muniz, M. Sandrini, and M. P. Belançon, The role of Ce3+/Ce4+ in the spectroscopic properties of cerium oxide doped zinc-tellurite glasses prepared under air, Journal of Non-Crystalline Solids 547, 120307 (2020).

- Han et al. [2015] B. Han, Y. Yang, J. Wu, J. Wei, Z. Li, and Y. Mai, Al2O3:Cr3+/tellurite glass composites: An efficient light converter for silicon solar cell, Ceramics International 41, 12267 (2015).

- Zhou et al. [2016] X. Zhou, J. Shen, Y. Wang, Z. Feng, R. Wang, L. Li, S. Jiang, and X. Luo, An Efficient Dual-Mode Solar Spectral Modification for c-Si Solar Cells in Tm3+/Yb3+ Codoped Tellurite Glasses, Journal of the American Ceramic Society 99, 2300 (2016).

- Garcia et al. [2019] J. A. Garcia, L. Bontempo, L. A. Gomez-Malagon, and L. R. Kassab, Efficiency boost in Si-based solar cells using tellurite glass cover layer doped with Eu3+ and silver nanoparticles, Optical Materials 88, 155 (2019).

- Zanuto et al. [2013] V. S. Zanuto, L. S. Herculano, M. L. Baesso, G. V. Lukasievicz, C. Jacinto, L. C. Malacarne, and N. G. Astrath, Thermal mirror spectrometry: An experimental investigation of optical glasses, Optical Materials 35, 1129 (2013).

- Sidek et al. [2009] H. Sidek, S. Rosmawati, Z. Talib, M. Halimah, and W. Daud, Synthesis and Optical Properties of ZnO-TeO2 Glass System, American Journal of Applied Sciences 6, 1489 (2009).

- Kut’in et al. [2019] M. Kut’in, D. Plekhovich, V. Balueva, S. E. Motorin, and V. V. Dorofeev, Thermal properties of high purity zinc-tellurite glasses for fiber-optics, Thermochimica Acta 673, 192 (2019).

- ast [2019] ASTM E927-19, Standard Classification for Solar Simulators for Electrical Performance Testing of Photovoltaic Devices, ASTM International, West Conshohocken, PA (2019).

- Kleine et al. [2020] T. S. Kleine, R. S. Glass, D. L. Lichtenberger, M. E. Mackay, K. Char, R. A. Norwood, and J. Pyun, 100th Anniversary of Macromolecular Science Viewpoint: High Refractive Index Polymers from Elemental Sulfur for Infrared Thermal Imaging and Optics, ACS Macro Letters 9, 245 (2020).

- Bleiwas [2010] D. I. Bleiwas, Byproduct Mineral Commodities Used for the Production of Photovoltaic Cells, Usgs 1365, 18 (2010).

- Wiesenfarth et al. [2018] M. Wiesenfarth, I. Anton, and A. W. Bett, Challenges in the design of concentrator photovoltaic (CPV) modules to achieve highest efficiencies, Applied Physics Reviews 5, 10.1063/1.5046752 (2018).

- Day et al. [2019] J. Day, S. Senthilarasu, and T. K. Mallick, Improving spectral modification for applications in solar cells: A review, Renewable Energy 132, 186 (2019).

- Wereszczak and Anderson [2014] A. A. Wereszczak and C. E. Anderson, Borofloat and Starphire Float Glasses: A Comparison, International Journal of Applied Glass Science 5, 334 (2014).

- Li et al. [2017] X. Li, L. Jiang, L. Li, and Y. Yan, Effects of HF etching on nanoindentation response of ion-exchanged aluminosilicate float glass on air and tin sides, Journal of Materials Science 52, 4367 (2017).

- Zheng et al. [2017] W. Zheng, L. Sheng, H. Chao, Z. Wang, S. Qian, Z. Peng, and C. Shen, Crystallization of CaO–MgO–Al2O3–SiO2 glass prepared by float process, Glass Physics and Chemistry 43, 347 (2017).

- Nayak et al. [2019] P. K. Nayak, S. Mahesh, H. J. Snaith, and D. Cahen, Photovoltaic solar cell technologies: analysing the state of the art, Nature Reviews Materials 10.1038/s41578-019-0097-0 (2019).

- Butler and Hooper [2011] J. H. Butler and P. Hooper, Glass Waste, in Waste (Elsevier, 2011) 2nd ed., pp. 151–165.

- Sidek et al. [2013] H. A. Sidek, S. Rosmawati, B. Z. Azmi, and A. H. Shaari, Effect of ZnO on the thermal properties of tellurite glass, Advances in Condensed Matter Physics 2013, 10.1155/2013/783207 (2013).

- Chabas et al. [2014] A. Chabas, S. Alfaro, T. Lombardo, A. Verney-Carron, E. Da Silva, S. Triquet, H. Cachier, and E. Leroy, Long term exposure of self-cleaning and reference glass in an urban environment: A comparative assessment, Building and Environment 79, 57 (2014).

- Barrioz et al. [2015] V. Barrioz, S. Monir, G. Kartopu, D. A. Lamb, W. Brooks, P. Siderfin, S. Jones, A. J. Clayton, and S. J. Irvine, MOCVD for solar cells, a transition towards a chamberless inline process, Journal of Crystal Growth 414, 223 (2015).

- Romero-Romo et al. [2021] W. Romero-Romo, S. Carmona-Téllez, R. Lozada-Morales, O. Soriano-Romero, U. Caldiño, M. E. Álvarez-Ramos, M. E. Zayas, and A. N. Meza-Rocha, Down-shifting and down-conversion emission properties of novel CdO–P2O5 invert glasses activated with Pr3+ and Pr3+/Yb3+ for photonic applications, Optical Materials 116, 10.1016/j.optmat.2021.111009 (2021).