Rheology of dense suspensions under shear rotation

Abstract

Dense non-Brownian suspensions exhibit a spectacular and abrupt drop in viscosity under change of shear direction, as revealed by shear inversions (reversals) or orthogonal superposition. Here, we introduce an experimental setup to systematically explore their response to shear rotations, where one suddenly rotates the principal axes of shear by an angle , and measure the shear stresses with a bi-axial force sensor. Our measurements confirm the genericness of the transient decrease of the resistance to shear under unsteady conditions. Moreover, the orthogonal shear stress, which vanishes in steady state, takes non-negligible values with a rich -dependence, changing qualitatively with solid volume fraction , and resulting in a force that tends to reduce or enhance the direction of flow for small or large . These experimental findings are confirmed and rationalized by particle-based numerical simulations and a recently proposed constitutive model. We show that the rotation angle dependence of the orthogonal stress results from a -dependent interplay between hydrodynamic and contact stresses.

Suspensions of non-Brownian hard particles form a large class of complex fluids [1, 2]. They are dense when solid and fluid are mixed in roughly equal proportion. Their widespread use in industry calls for proper constitutive characterization and modelling to enable reliable process design.

In steady state, their viscosity is either deformation-rate-independent [3, 4, 5] or slightly shear thinning [6, 7, 8, 9, 10]. Shear thickening is also observed when particles are repulsive beyond pure hard-core forces [11, 12], but we here focus on the strictly hard-sphere case. The viscosity increases with the solid volume fraction , and diverges at the jamming volume fraction [3, 4]. However, dense suspensions exhibit striking unsteady behaviors, e.g. the sharp viscosity drop in orthogonal superposition [13, 14, 15, 16, 17, 18, 19]. In shear reversal, where a suspension initially sheared in steady state under a deformation rate is suddenly sheared with a rate , the viscosity drops suddenly at reversal, passes through a minimum value and climbs up to its steady-state value after a few strain units [20, 21, 22, 23, 24, 25, 26, 27].

Under shear, suspensions develop an anisotropic micro-structure which takes up most of the stress at large concentrations [28, 29, 30, 11, 31, 32, 5, 24] and is built in a finite strain [20]. Upon shear reversal, the micro-structure is initially not compliant with the new direction of shear, leading to a viscosity dip which ends when the micro-structure is rebuilt in the new orientation [20]. This behavior may be a vestige of the fragility of jammed suspensions that can be made to flow by a change of applied load direction [33, 34, 35].

Characterization of the mechanical response to sudden changes of the strain axes, beyond shear reversal (which is the extreme case, as the compressional and elongational axes are swapped) [25, 26], is however absent. Here we fill this gap by considering the response to shear rotations, i.e. rotations of the strain axes by an arbitrary angle about the gradient direction. We perform shear rotations in experiments, with a specifically designed rheometer; simulations, using discrete element method (DEM); and the Gillissen-Wilson (GW) constitutive model [36, 37]. This gives us access to the viscosity drop as a function of angle and post-rotation strain . This also unveils a new non-Newtonian phenomenon: following a shear rotation, the shear viscosity orthogonal to the flow direction, , is transiently finite, reaching up to of the usual shear viscosity for large . Moreover, we show that the nature of angular dependence of depends on : while at moderate , shows a change of sign in , associated to a force resisting shear rotation for small values, for the largest values it keeps a constant sign. We show that this is due to the decreasing relative contribution of hydrodynamic stresses versus contact stresses when increases.

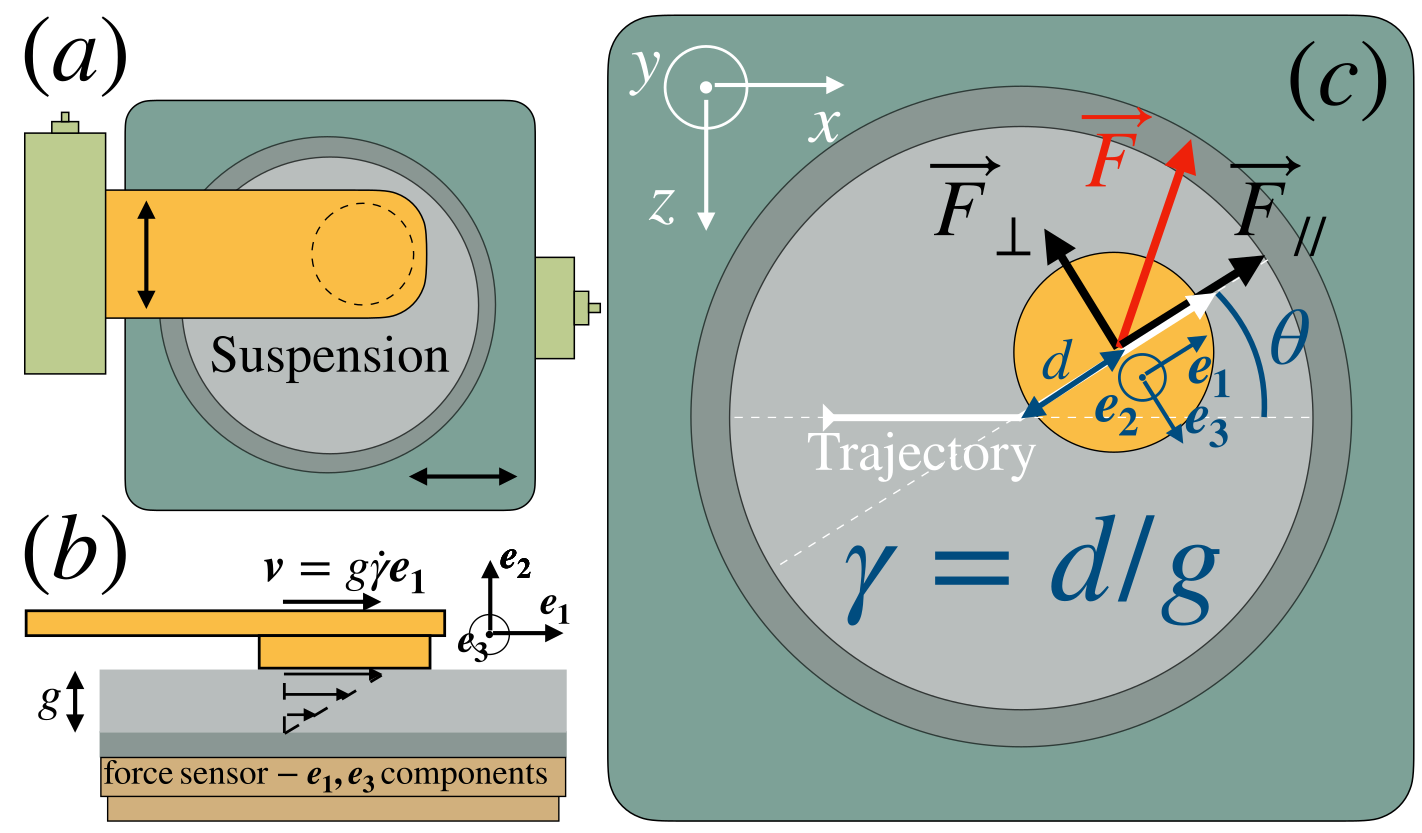

Experimental setup

We designed a cross rheometer [38, 39], sketched in Fig. 1, made with two parallel plates mounted on two motorized linear stages of 25mm stroke (Newport MFA-CC) acting in perpendicular directions, allowing for arbitrary relative parallel motion and therefore arbitrary simple shear with velocity gradient orthogonal to the plates. We apply a simple shear (Fig. 1(b)) with velocity gradient (with , and respectively the flow, gradient and vorticity directions), from which we define the strain-rate tensor . The shear rate is related to the velocity of the top plane relative to the bottom plane , being the gap width between the two plates.

A force sensor (AMTI HE6x6-1) measures the tangential force exerted on the lower plate (and thus by the upper plate on the suspension), with and respectively along and (Fig. 1(b)-(c)). We define the shear viscosity , with the area of the upper plate, as well as the “orthogonal” shear viscosity . Both have opposite -parities: is even, , while is odd, (in particular this enforces that and vanish).

A preshear is first applied over 10 strain units, which is enough to reach steady state, followed by a shear rotation where we rotate the flow direction and vorticity direction by an angle around the gradient direction (thick white line in Fig. 1(c)). The imposed shear rate is set at for all presented experimental data.

The viscosities and are recorded via a Data Acquisition System (USB-1608FS-PLUS, MCCDAQ) as a function of the subsequent strain . The strain resolution is , the lowest available strain is , and is sampled every .

The suspension particles are polystyrene spheres with a diameter of (Microbeads TS40). They are dispersed in poly(ethylene glycol-ran-propylene glycol) (Sigma-Aldrich, viscosity at , ) for suspensions at or silicone oil (M1000, Roth, at ) at and .

Numerics & model

We perform the same protocol in DEM simulations of a suspension of frictional particles subject to lubrication and contact forces in a tri-periodic configuration, using a method described in [39, 31]. The suspension is bidisperse (with a size ratio ) and the friction coefficient is , in order to match the viscosity values observed experimentally.

We also compare our results to the predictions of the GW model, a model capturing the features of shear reversal [36, 40]. A detailed derivation and discussion of the underlying assumptions of the GW model can be found in [37]. The GW model considers the strain evolution of a fabric tensor where is the unit separation vector between pairs of particles in a near interaction via contact or lubrication forces

| (1) |

The top line of Eq. (1) describes that particle pairs rotate like dumbbells with the velocity gradient and the bottom line describes the association and dissociation of particle pairs due to the compressive part and the extensive part of the strain rate tensor which pushes particles together and pulls them apart, respectively. The pair association (and dissociation) rate is a tuneable parameter. The tensor is approximated in terms of with the Hinch & Leal closure [41]. Furthermore, the GW model decomposes the stress in contributions from hydrodynamics, , and contacts, ,

| (2) |

where and are tuneable parameters. diverges when approaches the random close packing volume fraction and diverges when the ‘jamming coordinate’ , a proxy for the coordination number, approaches the jamming value . By demanding that, in steady shear flow, diverges when approaches the friction-dependent jamming volume fraction , we have previously shown that: [37]. In the SI we argue our choices for , and .

Results

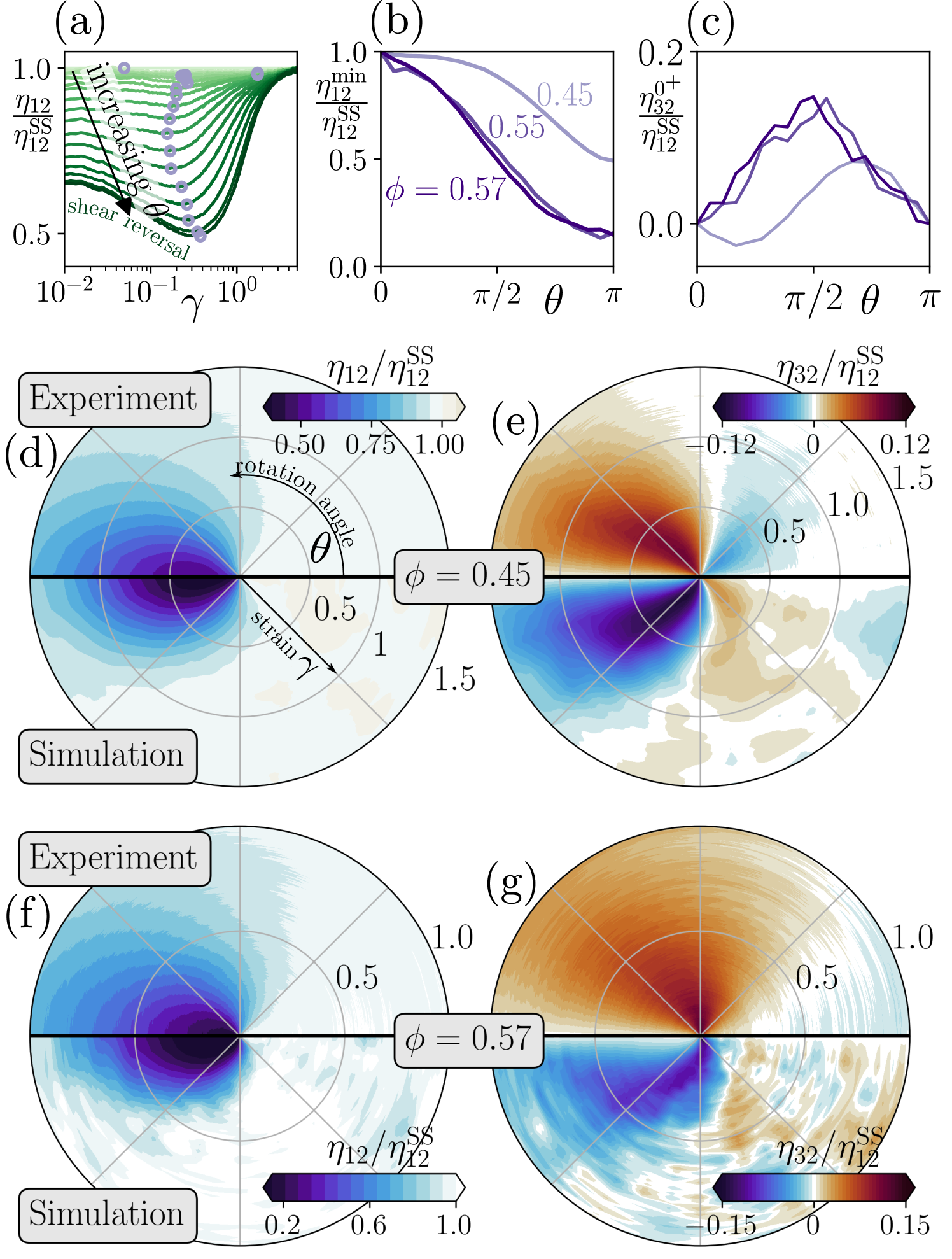

In Fig. 2(a), we show the viscosity measured in experiments, for a moderately dense suspension at . It decreases at low strain values, then passes through a minimum before increasing back to its steady-state value. The minimum is located at a strain weakly dependent on , from for to for shear reversal (). As shown in Fig. 2(b), the minimum value gradually decreases when increases, to reach its lowest value for shear reversal. Once normalized by the steady-state value , for a given decreases when increases, as is already known for shear reversal [25]. Interestingly, for the lowest , for : the suspension seems oblivious to the shear rotation at small angles. We will see that this is not quite true when considering .

We compare these data with the DEM ones in a radial representation in Fig. 2(d), with experiments in the top half and numerics in the bottom half. The agreement is good, besides simulations predicting a quicker relaxation to steady state than actually observed.

We turn in Fig. 2(e) to , again comparing experiments in the top half and numerics in the bottom half. Both datasets are in excellent agreement and reveal a structure mixing first and second order odd circular harmonics (respectively and ) with similar amplitudes. For , we find for , i.e. the suspension exerts on the top plate a “restoring” force in the direction of decreasing values. In a force control setup where one sets the upper plate force rather than its displacement, the suspension would thus be stable with respect to shear rotations, by rotating the velocity of the top plate towards lower values. By contrast, for , we find for , which can be interpreted as the suspension tending to rotate the trajectory of the top plate towards larger values.

In Fig. 2(f),(g), we show and for . Both experimental and numerical data show that the relaxation to steady state is quicker than at , with a smaller value [25, 27]. More importantly, the first harmonic of dominates. For , we find : the suspension always tends to push the top plate to move towards larger values, that is, the response is no longer stabilizing for small shear rotations. In Fig. 2(c), we highlight this qualitative change by showing the dependence of the values just after rotation .

Our simulations also show that the fabric evolution after shear rotation does not mimic the full stress response but only its contact contribution [39]. Notably, the fabric evolution does not exhibit any qualitative change upon increase of that we could correlate to the change of behavior of .

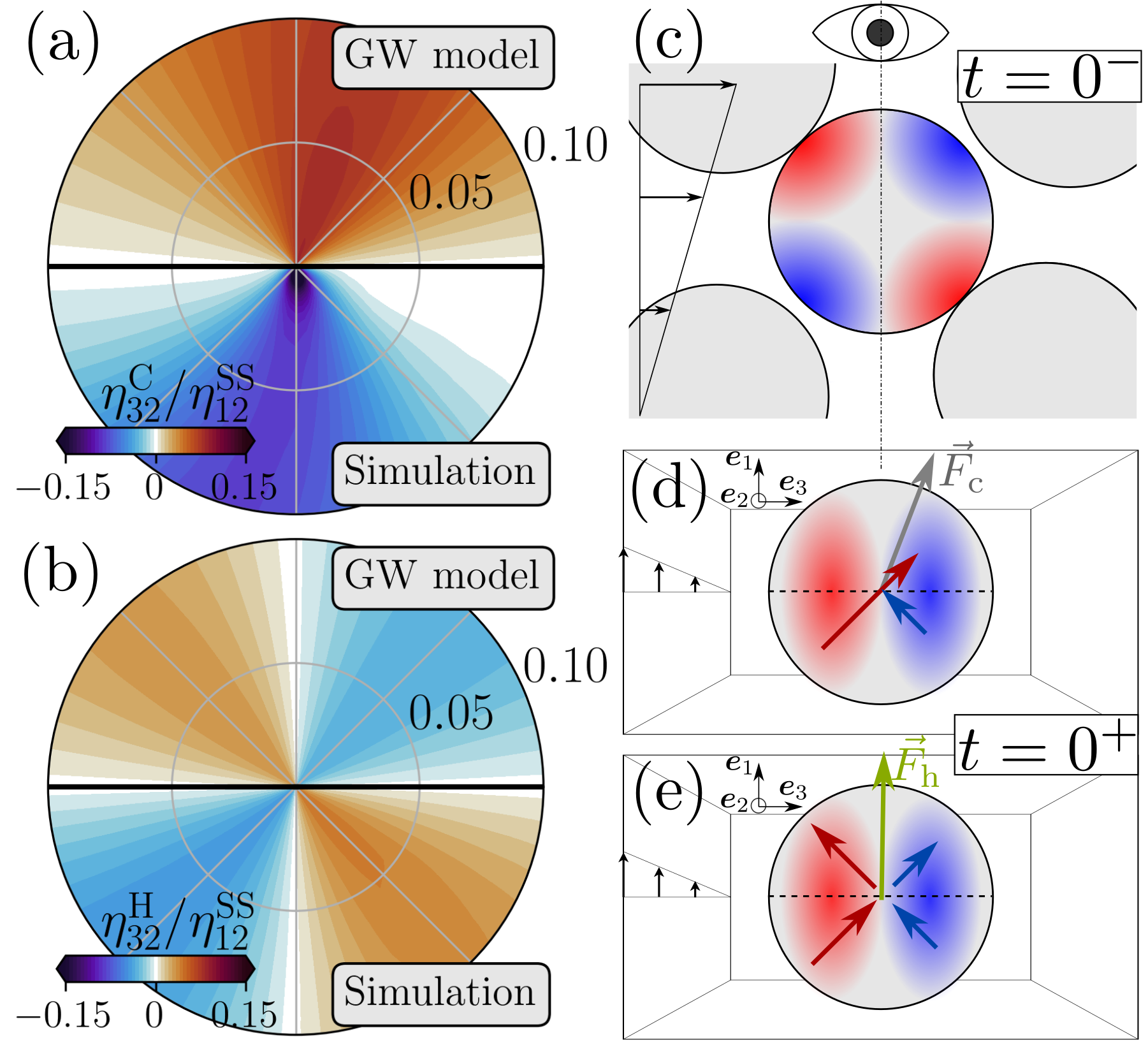

To understand the origin of the behavior, we interrogate the GW model and its predictions for the contact and hydrodynamic contributions to the stress response. As shown in Fig. 3(a), the contact contribution has a dominant first harmonic, with for . The large second harmonic of is instead due to the hydrodynamic component (Fig. 3(b)), which at still accounts for a substantial part of the total stress [32]. This is confirmed by numerical simulations, which compare well to the predictions of the model.

The difference between contact and hydrodynamic contributions can be qualitatively understood. In Fig. 3(c), we sketch in the shear plane a particle during preshear. It shows a fore-aft asymmetry: it has more near interactions (lubricated and in contact) in the compressional quadrants (in red) than in the elongational one (in blue). The same particle is seen from the gradient direction right after a shear rotation with in Fig. 3(d),(e). After rotation, the fore-aft asymmetry accumulated in preshear is a “left-right” asymmetry, and fore-aft symmetry is temporarily restored. Post-rotation contact stresses (Fig. 3(d)) stem from contacts in the post-rotation compressional quadrant, below the dashed line, and due to the left-right asymmetry, are dominated by contacts that carry over from the pre-rotation in the intersect of pre- and post-rotation compressional quadrants. Contact forces in this overlap region (red vector) are such that , giving a positive contribution to . By contrast, in Fig. 3(d), all interactions contribute hydrodynamic forces, and the fore-aft symmetry ensures that the hydrodynamic contribution from the post-rotation elongational and compressional quadrants share the same component, but have opposite component. This results in a net-zero hydrodynamic contribution to .

Whereas this reasoning can be extended to show that for , the sign of for depends on aspects of the distribution of near interactions that cannot be deduced from symmetry considerations. The GW model however gives us a quantitative picture alongside a microstructural insight. Calling the steady-state fabric in pre-shear, we get the following contributions to at [39]

| (3) | ||||

with

For the contact contribution, the first harmonic dominates for the values of and investigated. It is such that for . By contrast, the hydrodynamic contribution only has a second harmonic. Therefore, when is large enough, the four-lobed hydrodynamic response dominates, which happens at moderate . However, since contact stresses diverge for while hydrodynamic stresses diverge for , the two-lobed contact response takes over when moves closer to .

The sign of is not obvious, as it is set by . With our value of , we always find in the GW model. For small values, it therefore “stabilizes” the microstructure, as : it provides a restoring force acting against the rotation of the flow direction. In simulations, is measured tiny [27]. To test the GW model predictions, from our DEM simulations we compute based on particle pairs separated by at most a gap of times the average radius of the pair. We find , albeit decreasing in amplitude when increases. Interestingly, the value of becomes positive for small enough , which highlights how subtle the hydrodynamic stabilization is.

We performed shear rotations experimentally, numerically, and in a constitutive model, measuring both the shear viscosity and the orthogonal viscosity which is not measurable in a conventional rotational rheometer. It revealed a rich phenomenology. The shear viscosity exhibits a dip (except at small for the smallest explored here, ) on strain scales of order unity or less, and its amplitude increases upon increase of or . Remarkably, we find that during the post-rotation transient, with reaching up to of at , and of . The qualitative angular structure of depends on , which is explained by the predominance of either hydrodynamic or contact stresses. For , the second harmonic of is large as hydrodynamic stresses are significant, while for it is small as contact stresses dominate. Consequently, for small , produces a force that acts to reduce (stabilize) at smaller while it increases (destabilizes) at larger .

In an actual non-uniform or unsteady flow where strain axes rotation occur over a strain , we can define a Deborah-like number [42, 43], such that one should expect to observe the transient effects described here when . The decrease of under shear rotations has already been used to suggest energy-saving flow strategies [16, 17, 19], however the behavior of has so far been overlooked. Whereas in this work we impose the deformation and measure , in many cases one imposes the force or stress. A finite may lead to non-trivial trajectories, e.g. during the pulling or the sedimentation of an object in a dense suspension, especially if the suspension is not stable against shear rotations.

We have focused on a subset of the possible flow changes in a complex geometry. One would also need to characterize changes from simple shear to extensional flows and non-uniform flows, which are known to induce migration phenomena [44]. While characterizing all flow histories relevant for applications (or even a carefully selected subset) is a major task, our results show that it would certainly reveal non-trivial yet possibly important stress responses. The GW model captures the salient features of the stress response under shear rotation and in non-uniform flows [45], and could also prove an efficient design tool in this endeavour.

Acknowledgements.

Work funded in part by the European Research Council under the Horizon 2020 Programme, ERC grant agreement number 740269.

References

- Denn and Morris [2014] M. M. Denn and J. F. Morris, Annual Review of Chemical and Biomolecular Engineering 5, 203 (2014).

- Ness et al. [2022] C. Ness, R. Seto, and R. Mari, Annual Review of Condensed Matter Physics 13, 97 (2022).

- Ovarlez et al. [2006] G. Ovarlez, F. Bertrand, and S. Rodts, Journal of Rheology (1978-present) 50, 259 (2006).

- Boyer et al. [2011] F. Boyer, E. Guazzelli, and O. Pouliquen, Physical Review Letters 107, 188301 (2011).

- Guy et al. [2015] B. M. Guy, M. Hermes, and W. C. K. Poon, Physical Review Letters 115, 088304 (2015).

- Zarraga et al. [2000] I. E. Zarraga, D. A. Hill, and D. T. L. Jr, Journal of Rheology (1978-present) 44, 185 (2000).

- Dai et al. [2013] S.-C. Dai, E. Bertevas, F. Qi, and R. I. Tanner, Journal of Rheology (1978-present) 57, 493 (2013).

- Dbouk et al. [2013] T. Dbouk, L. Lobry, and E. Lemaire, Journal of Fluid Mechanics 715, 239 (2013).

- Vázquez-Quesada et al. [2016] A. Vázquez-Quesada, R. I. Tanner, and M. Ellero, Physical Review Letters 117, 108001 (2016).

- Lobry et al. [2019] L. Lobry, E. Lemaire, F. Blanc, S. Gallier, and F. Peters, Journal of Fluid Mechanics 860, 682 (2019).

- Seto et al. [2013] R. Seto, R. Mari, J. F. Morris, and M. M. Denn, Physical Review Letters 111, 218301 (2013).

- Wyart and Cates [2014] M. Wyart and M. E. Cates, Physical Review Letters 112, 098302 (2014).

- Ovarlez et al. [2010] G. Ovarlez, Q. Barral, and P. Coussot, Nature materials 9, 115 (2010).

- Barral [2011] Q. Barral, Superposition d’écoulements orthogonaux dans des fluides complexes: mise en place de l’expérience, application aux suspensions et aux fluides à seuil, Ph.D. thesis, Université Paris-Est (2011).

- Blanc et al. [2014] F. Blanc, E. Lemaire, and F. Peters, Journal of Fluid Mechanics 746, 10.1017/jfm.2014.160 (2014).

- Lin et al. [2016] N. Y. C. Lin, C. Ness, M. E. Cates, J. Sun, and I. Cohen, Proceedings of the National Academy of Sciences 113, 10774 (2016).

- Ness et al. [2018] C. Ness, R. Mari, and M. E. Cates, Science Advances 4, eaar3296 (2018).

- Ramaswamy et al. [2022] M. Ramaswamy, I. Griniasty, J. P. Sethna, B. Chakraborty, and I. Cohen, Incorporating tunability into a universal scaling framework for shear thickening (2022), arXiv:2205.02184 [cond-mat] .

- Acharya and Trulsson [2023] P. Acharya and M. Trulsson, Optimum dissipation by cruising in dense suspensions (2023), arXiv:2302.08810 [cond-mat] .

- Gadala‐Maria and Acrivos [1980] F. Gadala‐Maria and A. Acrivos, Journal of Rheology 24, 799 (1980), publisher: The Society of Rheology.

- Narumi et al. [2002] T. Narumi, H. See, Y. Honma, T. Hasegawa, T. Takahashi, and N. Phan-Thien, Journal of Rheology (1978-present) 46, 295 (2002).

- Kolli et al. [2002] V. G. Kolli, E. J. Pollauf, and F. Gadala-Maria, Journal of Rheology (1978-present) 46, 321 (2002).

- Blanc et al. [2011a] F. Blanc, F. Peters, and E. Lemaire, Journal of Rheology (1978-present) 55, 835 (2011a).

- Lin et al. [2015] N. Y. C. Lin, B. M. Guy, M. Hermes, C. Ness, J. Sun, W. C. K. Poon, and I. Cohen, Physical Review Letters 115, 228304 (2015).

- Peters et al. [2016] F. Peters, G. Giovanni, S. Gallier, F. Blanc, E. Lemaire, and L. Lobry, Journal of Rheology 60, 715 (2016).

- Ness and Sun [2016] C. Ness and J. Sun, Physical Review E 93, 012604 (2016).

- Chacko et al. [2018] R. N. Chacko, R. Mari, S. M. Fielding, and M. E. Cates, Journal of Fluid Mechanics 847, 700 (2018).

- Lootens et al. [2005] D. Lootens, H. van Damme, Y. Hémar, and P. Hébraud, Physical Review Letters 95, 268302 (2005).

- Blanc et al. [2011b] F. Blanc, F. Peters, and E. Lemaire, Physical Review Letters 107, 208302 (2011b).

- Blanc et al. [2013] F. Blanc, E. Lemaire, A. Meunier, and F. Peters, Journal of Rheology (1978-present) 57, 273 (2013).

- Mari et al. [2014] R. Mari, R. Seto, J. F. Morris, and M. M. Denn, Journal of Rheology (1978-present) 58, 1693 (2014).

- Gallier et al. [2014] S. Gallier, E. Lemaire, F. Peters, and L. Lobry, Journal of Fluid Mechanics 757, 514 (2014).

- Cates et al. [1998] M. E. Cates, J. P. Wittmer, J.-P. Bouchaud, and P. Claudin, Physical Review Letters 81, 1841 (1998).

- Seto et al. [2019] R. Seto, A. Singh, B. Chakraborty, M. M. Denn, and J. F. Morris, Granular Matter 21, 82 (2019).

- Giusteri and Seto [2021] G. G. Giusteri and R. Seto, Physical Review Letters 127, 138001 (2021).

- Gillissen and Wilson [2018] J. J. J. Gillissen and H. J. Wilson, Physical Review E 98, 033119 (2018).

- Gillissen et al. [2020] J. J. J. Gillissen, C. Ness, J. D. Peterson, H. J. Wilson, and M. E. Cates, Journal of Rheology 64, 353 (2020), publisher: The Society of Rheology.

- Lin et al. [2014] N. Y. C. Lin, J. H. McCoy, X. Cheng, B. Leahy, J. N. Israelachvili, and I. Cohen, Review of Scientific Instruments 85, 033905 (2014).

- [39] See Supplemental Material at [URL will be inserted by publisher] for the measured steady-state rheology, validation of the cross-rheometer, details on the Gillissen-Wilson model, calculations leading to Eq. (3), DEM implementation and simulation results for the post-rotation fabric evolution, which includes Refs. [45-51].

- Gillissen et al. [2019] J. J. J. Gillissen, C. Ness, J. D. Peterson, H. J. Wilson, and M. E. Cates, Physical Review Letters 123, 214504 (2019).

- Hinch and Leal [1976] E. J. Hinch and L. G. Leal, J. Fluid Mech. 76, 187 (1976).

- Macosko [1994] C. W. Macosko, Rheology: Principles, Measurements, and Applications, Advances in Interfacial Engineering Series (VCH, New York, 1994).

- Poole [2012] R. Poole, Rheol. Bull 53, 32 (2012).

- Guazzelli and Pouliquen [2018] É. Guazzelli and O. Pouliquen, Journal of Fluid Mechanics 852, P1 (2018).

- Gillissen and Ness [2020] J. J. J. Gillissen and C. Ness, Physical Review Letters 125, 184503 (2020).

- Jeffrey and Onishi [1984] D. J. Jeffrey and Y. Onishi, J. Fluid Mech. 139, 261 (1984).

- Ball and Melrose [1997] R. C. Ball and J. R. Melrose, Physica A 247, 444 (1997).

- Cundall and Strack [1979] P. A. Cundall and O. D. L. Strack, Geotechnique 29, 47 (1979).

- Brady and Bossis [1988] J. F. Brady and G. Bossis, Ann. Rev. Fluid Mech. 20, 111 (1988).

- Arshad et al. [2021] M. Arshad, A. Maali, C. Claudet, L. Lobry, F. Peters, and E. Lemaire, Soft Matter 17, 6088 (2021).

- Bounoua et al. [2019] S. N. Bounoua, P. Kuzhir, and E. Lemaire, Journal of Rheology 63, 785 (2019).