University of Arkansas, USAawalseth@uark.eduhttps://orcid.org/0000-0002-0055-0788This author’s work was supported in part by NSF grant CAREER-1553166University of Arkansas, USAdhader@uark.eduThis author’s work was supported in part by NSF grant CAREER-1553166University of Arkansas, USApatitz@uark.eduhttps://orcid.org/0000-0001-9287-4028This author’s work was supported in part by NSF grant CAREER-1553166\CopyrightAndrew Alseth, Daniel Hader, and Matthew J. Patitz{CCSXML} <ccs2012> <concept> <concept_id>10003752.10003753</concept_id> <concept_desc>Theory of computation Models of computation</concept_desc> <concept_significance>500</concept_significance> </concept> </ccs2012> \ccsdesc[500]Theory of computation Models of computation \EventEditorsJohn Q. Open and Joan R. Access \EventNoEds28 \EventLongTitle28th International Conference on DNA Computing and Molecular Programming \EventShortTitleDNA28 \EventAcronymDNA \EventYear2022 \EventDateAugust 8–12, 2022 \EventLocationAlbuquerque, New Mexico, USA \EventLogo \SeriesVolume \ArticleNo

Universal Shape Replication Via Self-Assembly With Signal-Passing Tiles

Abstract

In this paper, we investigate shape-assembling power of a tile-based model of self-assembly called the Signal-Passing Tile Assembly Model (STAM). In this model, the glues that bind tiles together can be turned on and off by the binding actions of other glues via “signals”. Specifically, the problem we investigate is “shape replication” wherein, given a set of input assemblies of arbitrary shape, a system must construct an arbitrary number of assemblies with the same shapes and, with the exception of size-bounded junk assemblies that result from the process, no others. We provide the first fully universal shape replication result, namely a single tile set capable of performing shape replication on arbitrary sets of any 3-dimensional shapes without requiring any scaling or pre-encoded information in the input assemblies. Our result requires the input assemblies to be composed of signal-passing tiles whose glues can be deactivated to allow deconstruction of those assemblies, which we also prove is necessary by showing that there are shapes whose geometry cannot be replicated without deconstruction. Additionally, we modularize our construction to create systems capable of creating binary encodings of arbitrary shapes, and building arbitrary shapes from their encodings. Because the STAM is capable of universal computation, this then allows for arbitrary programs to be run within an STAM system, using the shape encodings as input, so that any computable transformation can be performed on the shapes.

keywords:

Algorithmic self-assembly, Tile Assembly Model, shape replicationcategory:

\relatedversion1 Introduction

Artificial self-assembling systems are most often designed with the goal of building structures “from scratch”. That is, they are designed so that they will start from a disorganized set of relatively simple components (often abstractly called tiles) that autonomously combine to form more complex target structures. This process often begins from collections of only unbound, singleton tiles, or sometimes also includes so-called seed assemblies which may be small (in relation to the target structure) “pre-built” assemblies that encode some information which seeds the growth of larger assemblies. This growth occurs as additional tiles bind to those seed assemblies according to the rules of the system, allowing them to eventually grow into the desired structures. Examples have been shown in both experimental settings (e.g. [11, 32, 16]), as well as in the mathematical domains of abstract models (e.g. [29, 27, 6, 10, 8]). However, in the subdomain of algorithmic self-assembly, in which systems are designed so that the tile additions implicitly follow the steps of pre-designed algorithms, other goals have also been pursued. These have included, for instance, performing computations (e.g. [18, 25]), identifying input assemblies that match target shapes [26], replicating patterns on input assemblies [17, 28], and replicating (the shapes of) input assemblies [5, 20, 1, 3, 13]. In this paper, we explore the latter, particularly the theoretical limits of systems within a mathematical model of self-assembling tiles to replicate shapes.

We use the term shape replication to refer to the goal of designing self-assembling systems that take as input seed assemblies and which produce new assemblies that have the same shapes as those seed assemblies [1]. In order for tile-based self-assembling systems to perform shape replication, dynamics beyond those of the original abstract Tile Assembly Model (aTAM), introduced by Winfree [31] and widely studied (e.g. [29, 27, 10, 18, 4, 22, 14, 19]), are required. In the aTAM, tiles attach to the seed assembly and the assemblies which grow from it, one tile at a tile, and tile attachments are irreversible. A generalization of the aTAM, the hierarchical assembly model known as the 2-Handed Assembly Model [4, 6], allows for the combination of pairs of arbitrarily large assemblies, but it too only allows irreversible attachments. However, for shape replication, it is fundamentally important that at least some tiles are able to bind to the input assemblies to gather information about their shapes which is then used to direct the formation of the output assemblies, since binding to an assembly is the only mechanism for interacting with it. These output assemblies eventually must not be connected to the input assemblies if they are to have the same shapes as the original input assemblies. This requires that at some point tile bindings can be broken. A number of theoretical models have been proposed with mechanisms for breaking tiles apart, for example: glues with repulsive forces [24, 21], subsets of tiles which can be dissolved at given stages of assembly [1, 9], tiles which can turn glues on and off [23, 15] (a.k.a. signal-passing tiles), and systems where the temperature can be increased to cause bonds to break [6, 30]. Within these models, previous results have shown the power of algorithmic self-assembling systems to perform shape replication. In [5], they used glues with repulsive forces, and in [1] they used the ability to dissolve away certain types of tiles at given stages during the self-assembly process, and each showed how to replicate a large class on two-dimensional shapes. In [13], signal-passing tiles were shown to be capable of replicating arbitrary hole-free two-dimensional shapes if they are scaled up by a factor of 2. The results of [3] deal with the replication of three-dimensional shapes, and will be further discussed below.

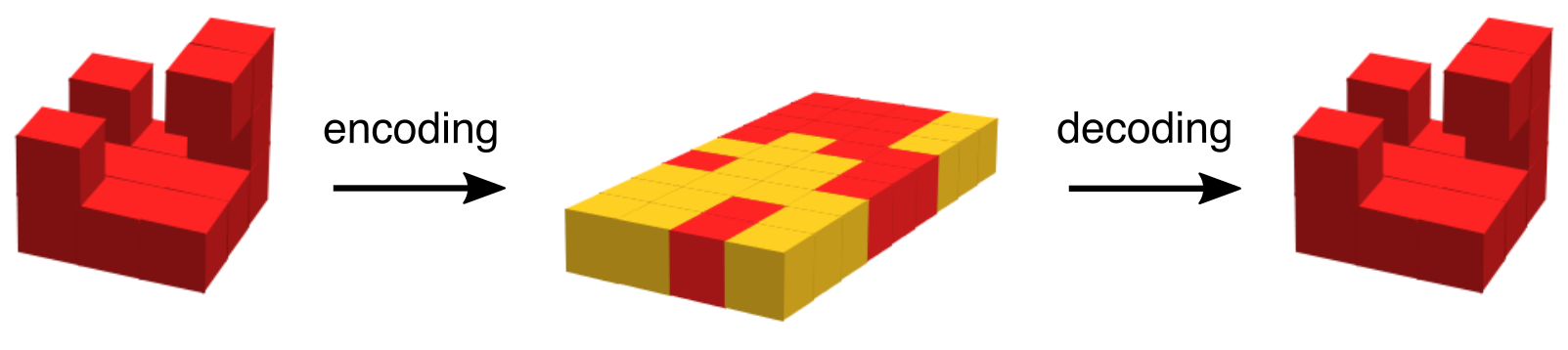

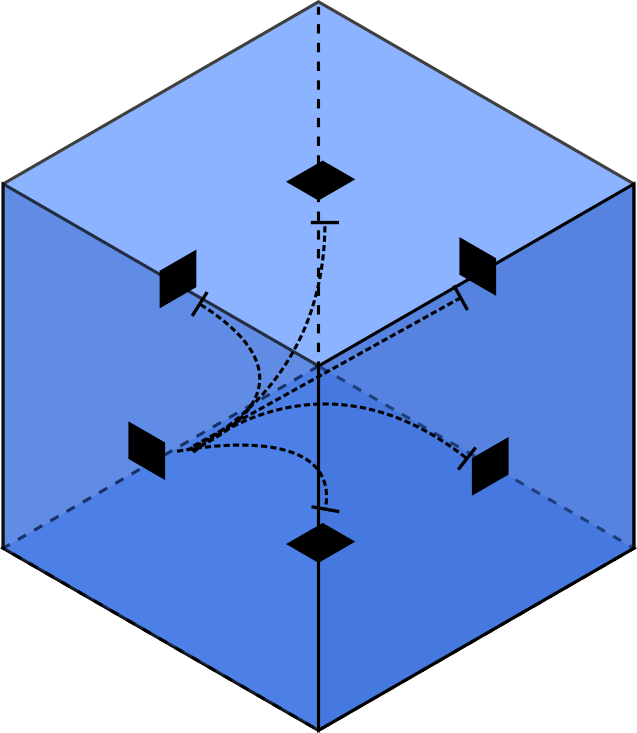

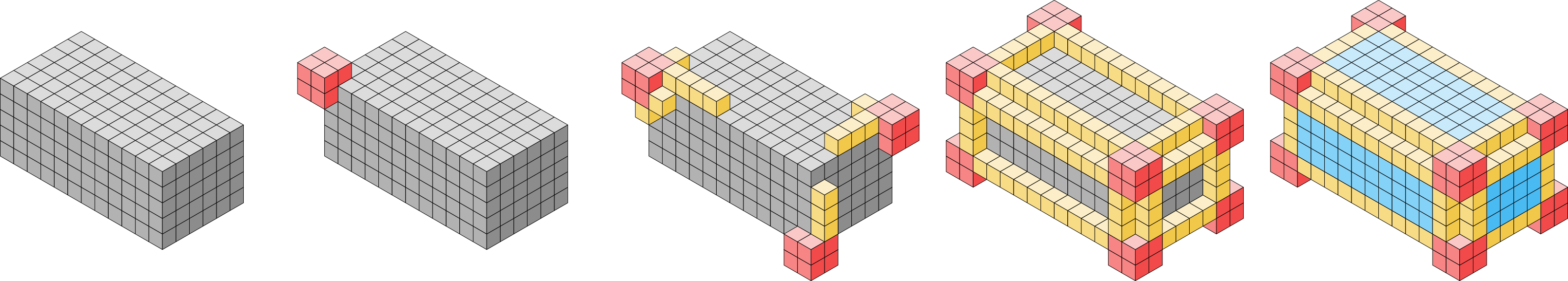

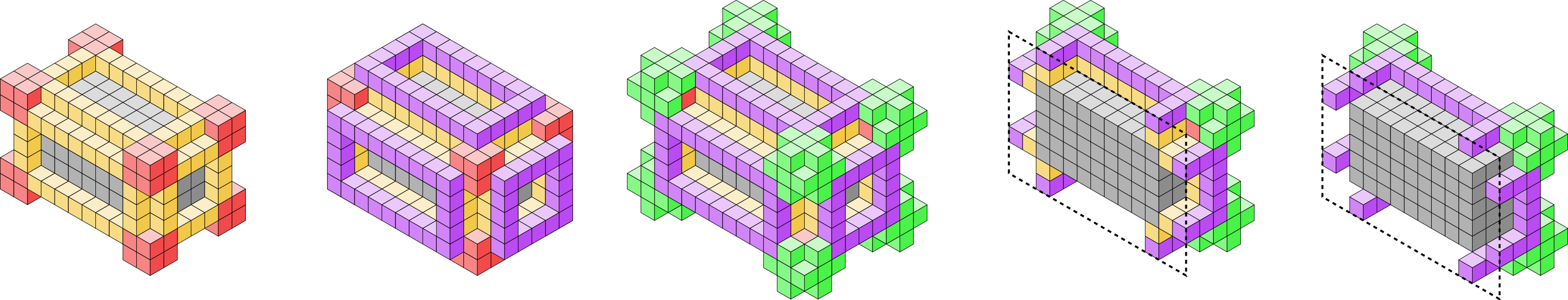

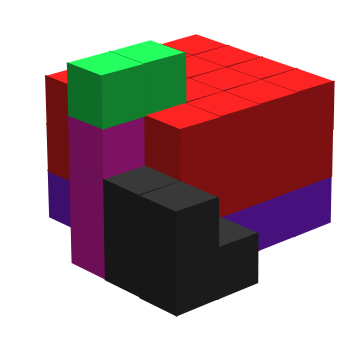

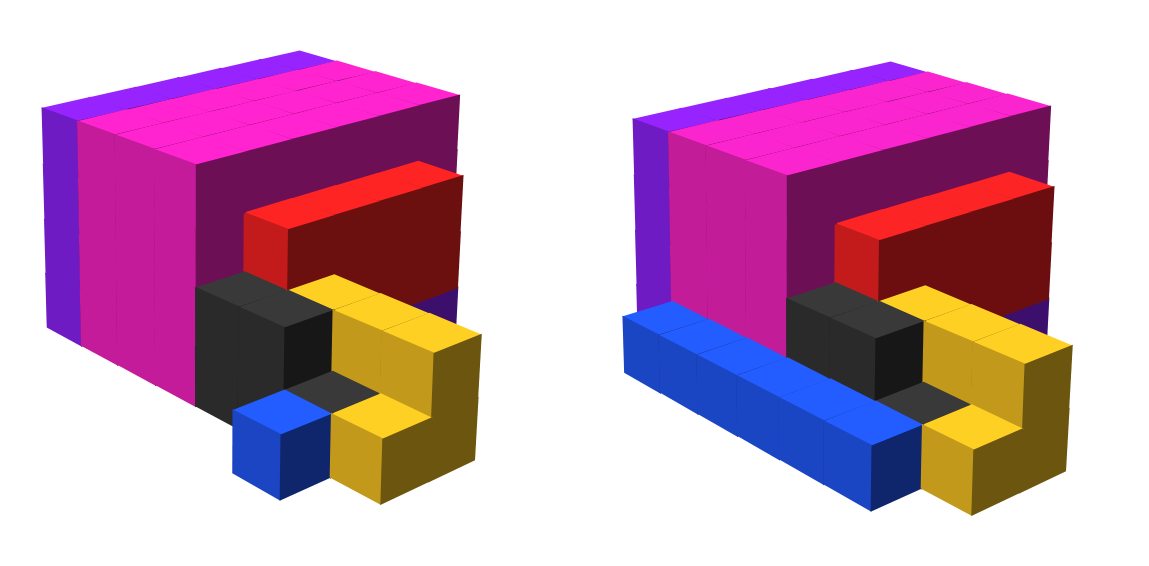

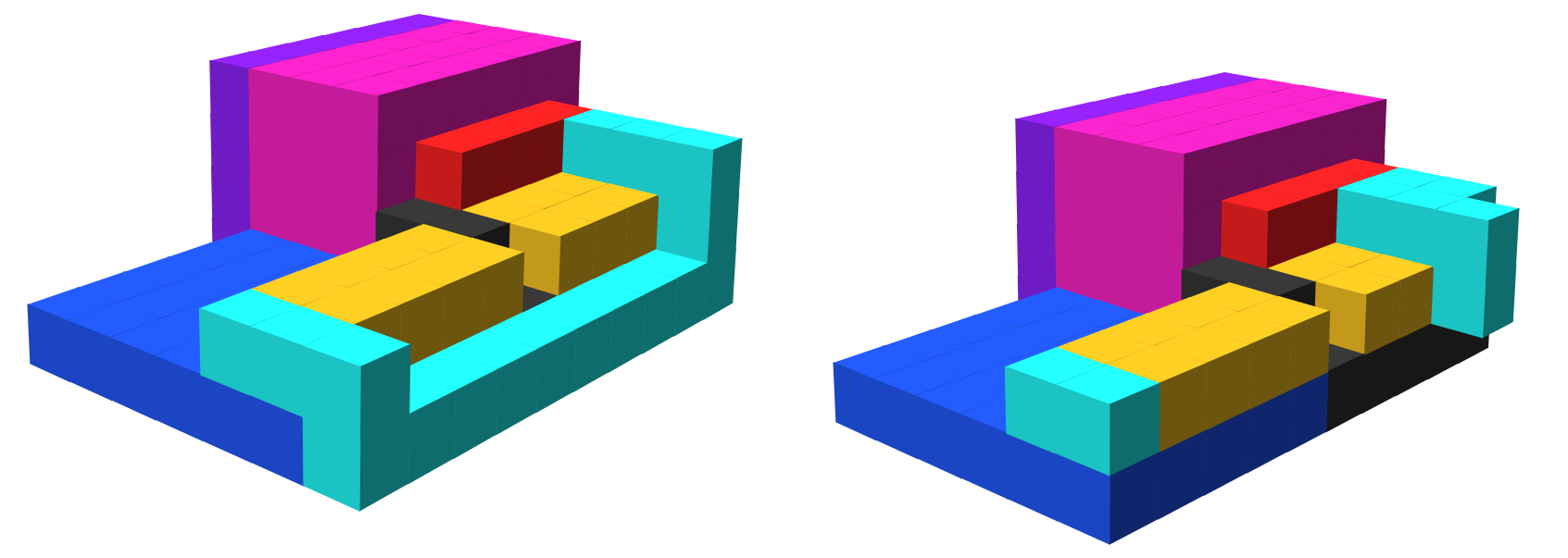

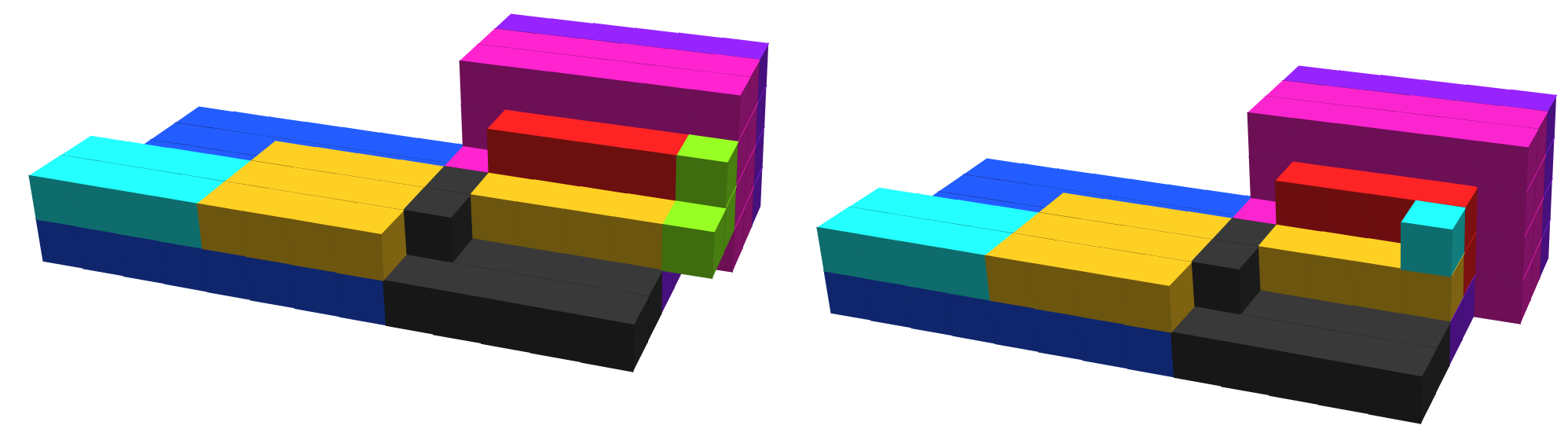

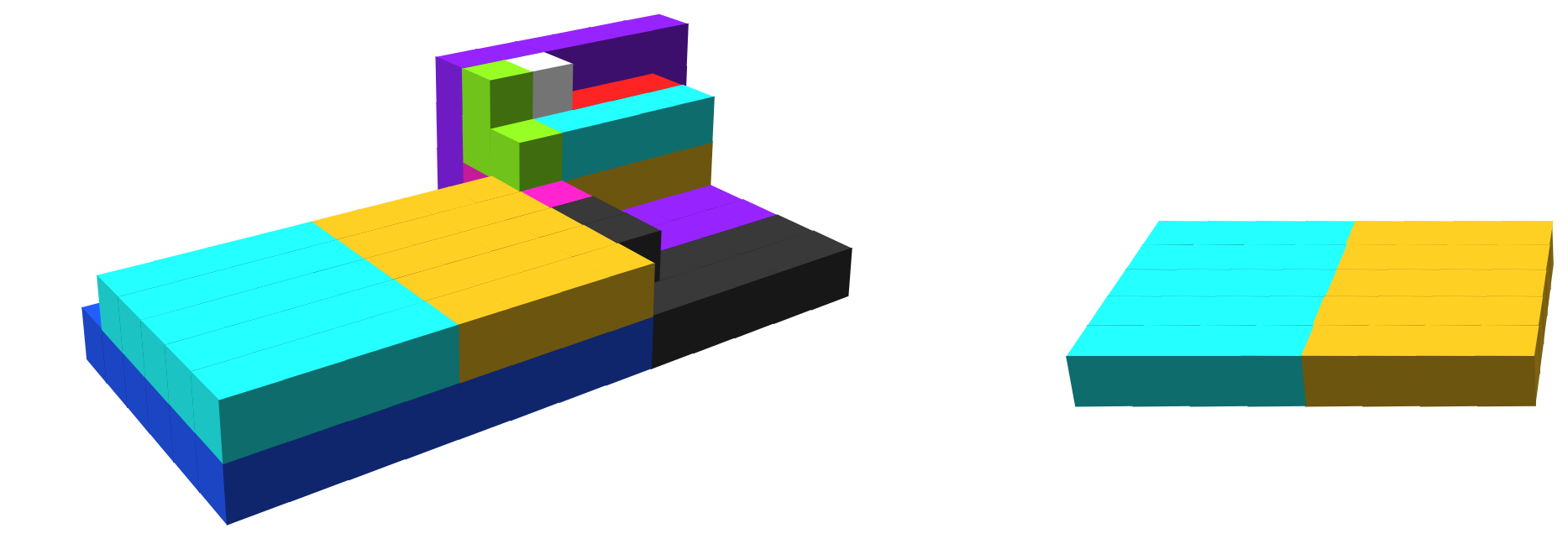

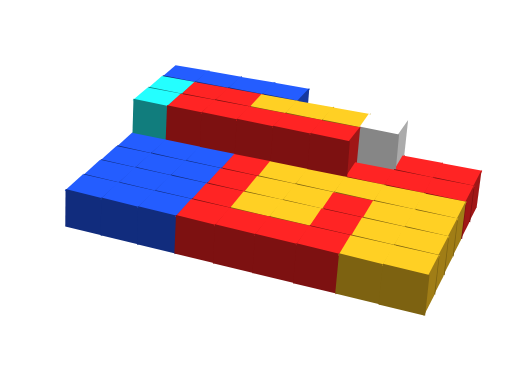

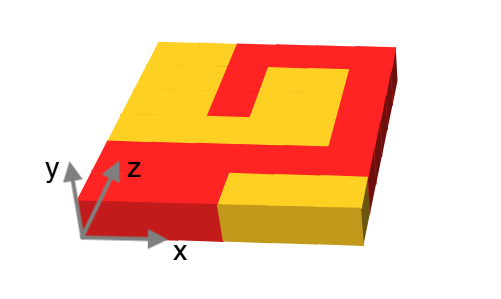

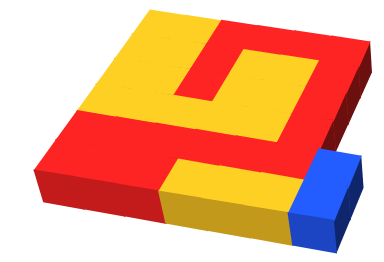

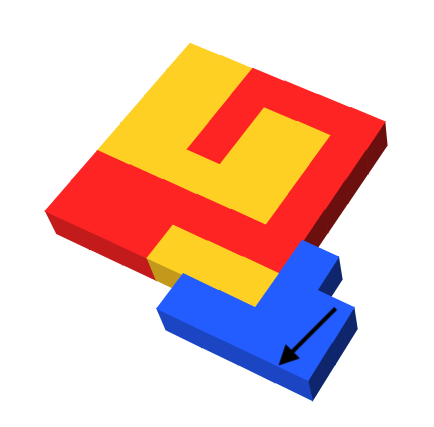

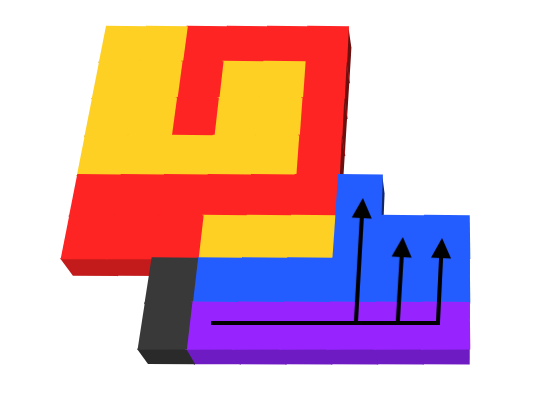

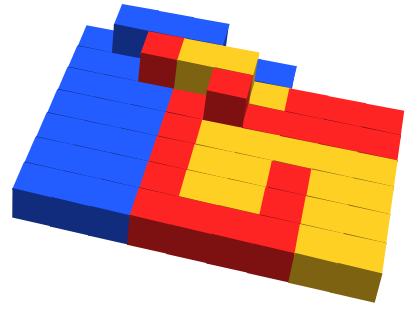

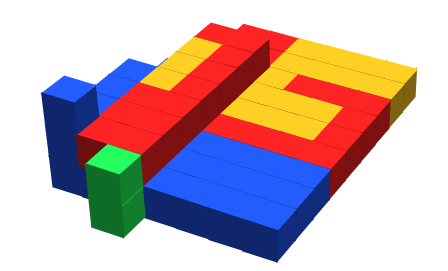

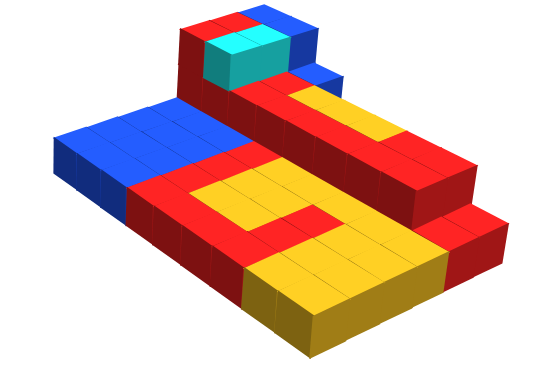

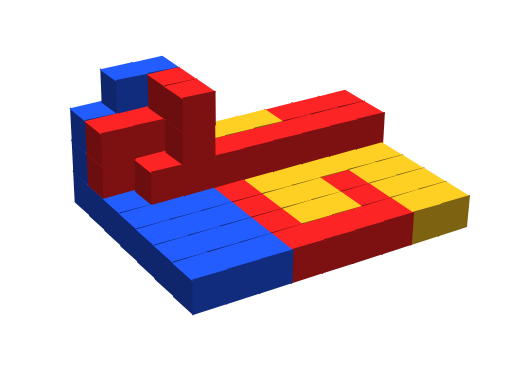

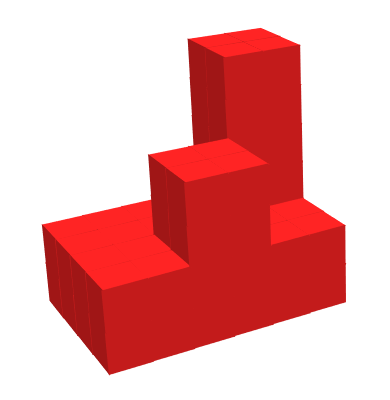

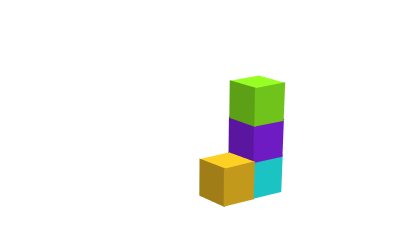

The results of this paper are the first which provide for shape replication of all 3-dimensional shapes with no requirement for scaling those shapes. Additionally, although in [3] all three-dimensional shapes can be replicated at the small scale factor of 2, there it is necessary for the input assemblies to have relatively complex information embedded within them (in the form of Hamiltonian paths through all of their points being encoded by their glues). In our results, the input assemblies require no such embedded information. Furthermore, the model used in [3] is more complex, allowing not only for hierarchical assembly and signal-passing tiles, but also for tiles of differing shapes, and glue bindings that are flexible and thus allow for assemblies to reconfigure by folding. For the results of this paper, we have not only limited the dynamics to those of the Signal-Passing Tile Assembly Model (STAM), but have even placed an additional restriction on the model. Rather than assigning fixed orientations to tiles, in the model we use and call the STAMR (i.e. the “STAM with rotation”) tiles and assemblies are allowed to rotate. This allows us to consider an even more general, and difficult, version of the shape replication problem. Namely, the input assemblies in our constructions have glues of a single generic type covering their entire exteriors, and there is no distinction between a north-facing glue and an east-facing glue, for instance, as there is in the standard STAM. This makes several aspects of working with such generic input assemblies more difficult, but it is notable that our constructions need only trivial, simplifying modifications to work in the standard STAM and that our positive results thus also hold for the STAM. We show that there is a “universal shape replicator” which is a tileset in the STAMR that can be used in conjunction with any set of generic input assemblies and will cause assemblies of every shape in the input set to be simultaneously produced in parallel. This is the first truly universal shape replicator for two or three dimensional shapes111Note that while replicating two-dimensional shapes, which consist of points in a single plane, our construction will utilize three dimensions.. Furthermore, we break our construction into two major components, a “universal encoder” and a “universal decoder” (see Figure 1 for a depiction). The universal encoder is capable of taking generic input assemblies and creating assemblies that expose binary sequences that encode those shapes, and the universal decoder is capable of taking assemblies exposing those encodings and creating assemblies of the encoded shapes. Due to the Turing universality of this model, this also allows for the full range of all possible computational transformations to occur between the encoding and decoding, and thus enables the generation of any transformations of the shapes of the input assemblies, such as creating scaled versions or complementary shapes.

In order for our universal shape replication construction to operate, the input assemblies must be created from signal-passing tiles which are capable of turning off their glues and dissociating from the assemblies. This allows for the assemblies to be “deconstructed”, and we prove that this is necessary in order to replicate arbitrary shapes, specifically those which have enclosed or narrow, curved cavities, and this is intuitively clear since otherwise there would be no way to determine which locations in the interior of an input shape are included in the shape, and which are part of an enclosed void. Our proof that it is also impossible to replicate shapes with curved, but not enclosed, cavities further exhibits the additional difficulty of working within the STAMR model which allows tile rotations.

While our universal shape encoder, decoder, and replicator achieve the full goal of the line of research into shape replication, and also provide the ability to augment shape-building with arbitrary computational transformations, we note that the results are highly theoretical and serve more generally as an exploration of the theoretical limits of self-assembling systems. The tilesets are relatively large and require tiles with large numbers of signals, and although the input assemblies are not required to have complex information embedded within them, a trade-off that occurs compared with the results of [3] is that our constructions make use of a large amount of “fuel”. That is, a large number of tiles are used during various phases but they are only temporary and aren’t contained within the target assemblies and thus are “consumed” by the construction process. Despite the complexity of these theoretical constructions, we think that several modules and techniques developed may be of future use within other constructions (e.g. our “leader election” procedure which is guaranteed to uniquely select a single corner of an input assembly’s bounding prism, to serve as a staring location for our encoding procedure within a constant number of assembly steps despite the lack of directional information provided by such an assembly), and also that these results may lead the way to similarly powerful but less complex constructions that may eventually achieve a level of being physically plausible to construct.

This paper is organized as follows. In Section 2 we provide definitions of the STAMR and other terminology used throughout the paper, plus a series of subconstructions that appear throughout the main constructions. In Section 3 we state our main theorem and supporting lemmas, and present the constructions that prove them. In Section 4 we show that the constructions can be easily adapted to also work in the standard STAM. In Section 5 we briefly describe some of the computational transformations that could be used to augment our constructions, and in Section 6 we prove deconstruction is necessary for shape replication of certain classes of shapes.

2 Definitions

In this section we provide definitions of the model used, and also for several of the terms and subconstructions used throughout the paper.

2.1 Definition of the STAMR model

Here we provide a definition of the model used in this paper, called the STAMR (i.e. the “STAM with rotation”), which is based upon the 3D Signal-passing Tile Assembly Model (STAM) [12]. The STAM is itself based upon the 2-Handed Assembly Model (2HAM) [6, 7], also referred to as the “Hierarchical Assembly Model”, which is a mathematical model of tile-based self-assembling systems in which arbitrarily large pairs of assemblies can combine to form new assemblies.

A glue is an ordered pair , where is a non-empty string, called the label, over some alphabet , possibly concatenated with the symbol ‘∗’, and is a positive integer, called the strength. A glue label is said to be complementary to the glue label .

A tile type is a mapping of zero or more glues, along with glue states and possibly signals, which will be defined shortly, to the faces of a unit cube. A tile is an instance of a tile type, and is the base component of the STAMR. Each tile type is defined in a canonical orientation, but tiles can be in that orientation or any rotation which is orthogonal to it (i.e. they are embedded in ).

Every glue can be in one of three glue states: . If two tiles are placed next to each other, and their adjacent faces have glues and , then those glues can form a bond whose strength is . We require any copies of glues with the label , or its complement , in any given system have the same strength (e.g. it is not allowed to have one glue labeled with strength and another labeled or with strength ).

A signal is a mapping from a glue (the source glue) to an ordered pair, , where (the target glue) is a glue on the same tile as (possibly itself) and . If and when forms a bond with its complementary glue on an adjacent tile, the signal is fired to change the state of to state . Each glue of a tile type can be defined to have zero or more signals assigned to it. Each signal on a tile can fire at most a single time. When a glue is fired, the state of the target glue is not immediately changed, but the pair is added to a queue of pending signals for the tile containing its glues. When a pending glue is selected for completion (in a process described below), then the state of is changed to if and only if its current state is and . That is, the only valid glue state transitions are on to off, or latent to on or off.

A supertile is (the set of all translations and rotations of) a positioning of one or more connected tiles on the integer lattice . Two adjacent tiles in a supertile can form a bond if the glues on their abutting sides are complementary and both are in the on state. Each supertile induces a binding graph, a grid graph whose vertices are tiles, with an edge between every pair of bound tiles whose weight is the strength of the bound glues. A supertile is -stable if every cut of its binding graph cuts edges whose weights sum to at least . That is, the supertile is -stable if at least energy is required to separate the supertile into two parts. Assembly is another term for a supertile, and we use the terms interchangeably, to mean the same thing.

Each tile has a tile state that contains the current state of every glue as well as a (possibly empty) set of pending signals and a (possibly empty) set of completed signals. Every supertile consists of not only its set of constituent tiles, but also their tile states, and a set bonds that have formed between pairs of glues on adjacent tiles.

A system in the STAMR is an ordered triple where is a finite set of tiles called the tileset, is a system state which consists of a multiset of supertiles that each have a count (possibly infinite), and is the binding threshold (a.k.a. temperature) parameter of the system which specifies the minimum strength of bonds needs to hold a supertile together. In the initial state of a system, no tiles have pending signals, all pairs of adjacent glues which are both complementary and in the on state in all supertiles have formed bonds and any signals which would have been fired by those bonds are completed, and all distinct supertiles are assumed to start arbitrarily far from each other (i.e. none is enclosed within another). By default (and unless otherwise specified), the initial state contains an infinite count of all singleton tiles in .

A system evolves as a (possibly infinite) series of discrete steps, called an assembly sequence, beginning from its initial state. Each step occurs by the random selection and execution of one of the following actions:

-

1.

Two supertiles currently in the system, and , are translated and/or rotated without ever overlapping so that they can form bonds whose strengths sum to at least . The count of the newly formed supertile is increased by in the system state and the counts of each of and are decreased by (if they aren’t ). In the newly created supertile, from the entire set of pairs of glues which can form bonds, a random subset whose strengths sum to is selected and bonds formed by those glues are added to the set of bonds that have formed for that supertile. Additionally, for each glue which forms a bond, all signals for which it is a source glue, but which aren’t already pending or completed, are added to the set of pending signals for its tile.

-

2.

For any supertile currently in the system, from the set of pairs of glues which can form bonds but haven’t, a glue pair is selected and a bond formed by those glues is added to the set of bonds that have formed for that supertile. Additionally, for each glue which forms that bond, all signals for which it is a source glue, but which aren’t already pending or completed, are added to the set of pending signals for its tile.

-

3.

For any supertile currently in the system, a pending signal is selected from the set of pending signals of one of its tiles. If the action specified by that signal is valid, the state of the target glue is changed to the state specified by the signal. The signal is removed from the set of pending signals and added to the set of completed signals. If the action is not valid (i.e. the pair specifying the current state of the target glue and the desired end state is not in ), then the signal is just removed from the pending set and added to the completed set, and there is no change to the target glue.

-

4.

For a supertile currently in the system for which there exists one or more cuts of (which could be the case due to one or more glues changing to the off state), one of those cuts is randomly selected and is split into two supertiles, and , along that cut. The count of in the system state is decreased by one (if it isn’t ) and the counts of and are increased by one (if they aren’t ).

Given a system , a supertile is producible, written as , if it either is contained in the initial state or it can be formed, starting from , by any series of the above steps. A supertile is terminal, written as , if it is producible and none of the above actions are possible to perform with it (and any other producible assembly, for list item 1).

Note that tiles are not allowed to diffuse through each other, and therefore a pair of combining supertiles must be able to translate and/or rotate without ever overlapping into positions for binding. It is allowed, though, for two supertiles, and , to translate and/or rotate into locations which are partially enclosed by another supertile before binding, potentially creating a new supertile, , which would not have been able to translate and/or rotate into that location inside , without overlapping , after forming. However, although the model allows for supertiles to assemble “inside” of others, in order to strengthen our results we do not utilize it for the constructions of our positive results, but its possibility does not impact our negative result.

Definition 2.1.

Given an STAMR system , we say that it finitely completes with respect to a set of terminal assemblies if and only if there exists some constant such that, if in the initial configuration , each element of was assigned count , in every possible valid assembly sequence of , every element of is produced.

A system which finitely completes with respect to assemblies is guaranteed to always produce those assemblies as long as it begins with enough copies of the (super)tiles in its initial configuration, i.e. it cannot follow any assembly sequence which would consume one or more (super)tiles needed to form those assemblies before making them.

Definition 2.2.

A shape is a non-empty connected subset of , i.e. a connected set of unit cubes each of which is centered at a coordinate . A finite shape is a finite connected subset of .

In this paper, we consider shapes to be equivalent up to rotation and translation and unless stated otherwise explicitly, we will use the word shape to refer only to finite shapes.

Definition 2.3.

Given a shape , a bounding box is a rectangular prism in which completely contains . The minimum bounding box is the smallest such rectangular prism.

Definition 2.4.

Given a shape , we use the term enclosed cavity in to refer to a set of connected points in that are not contained in and for which no path in exists that does not intersect at least one point in and gets infinitely far from all points in .

Definition 2.5.

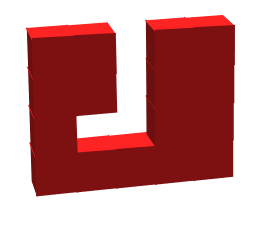

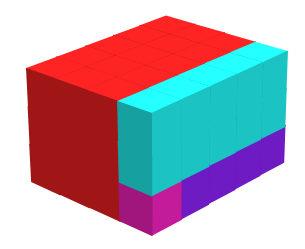

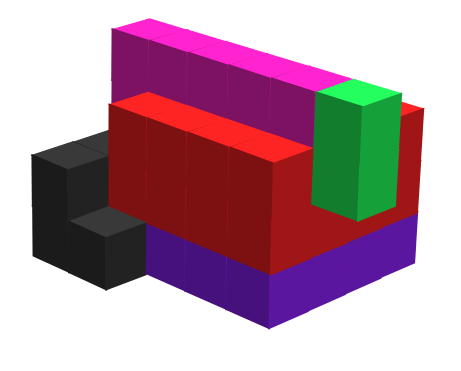

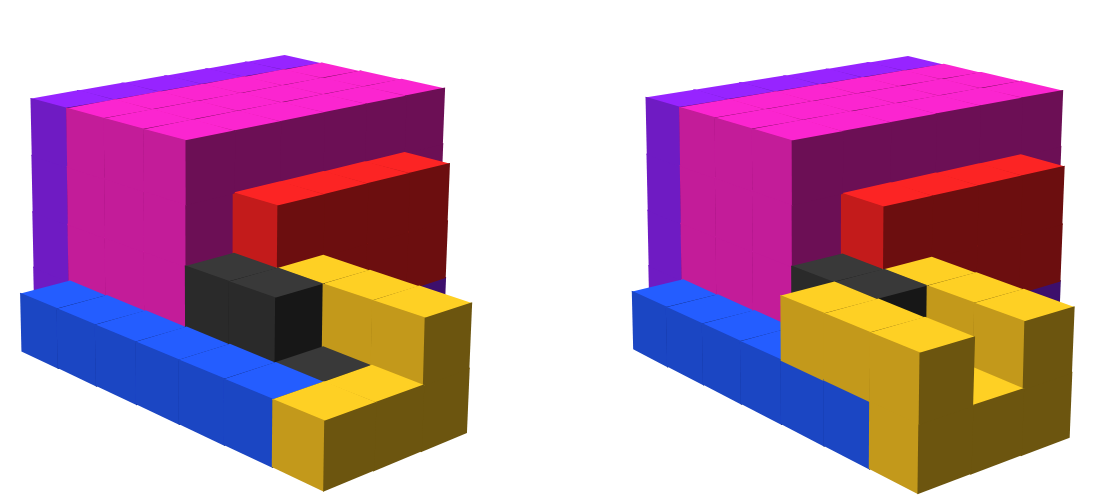

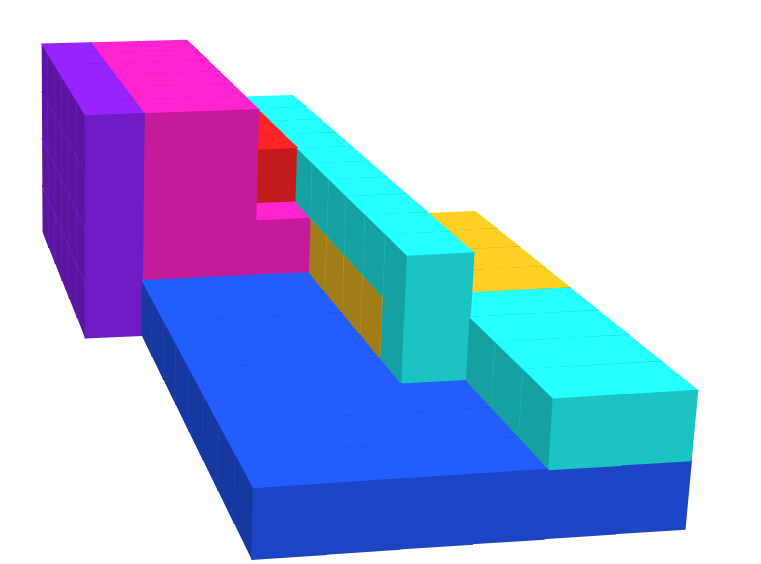

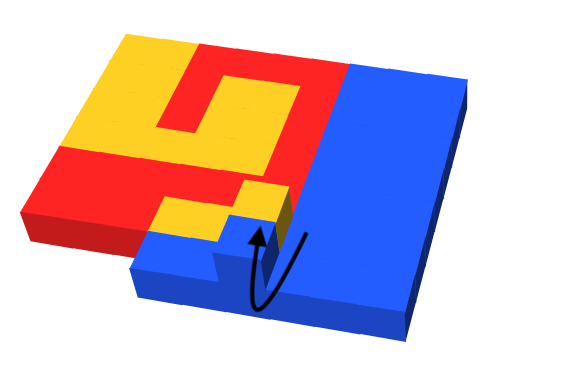

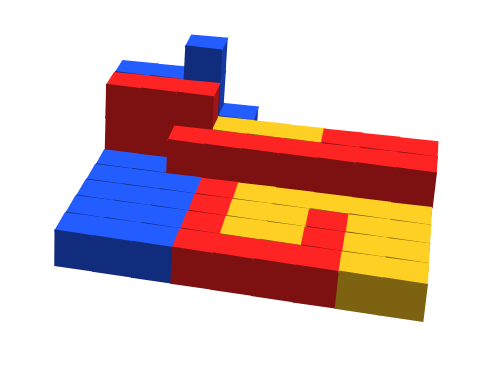

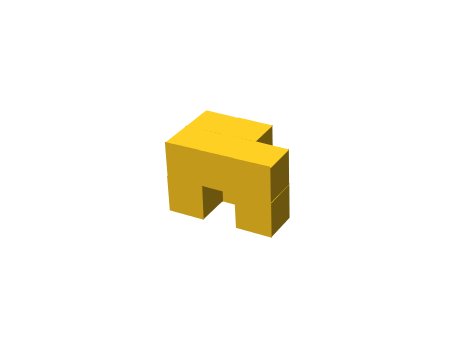

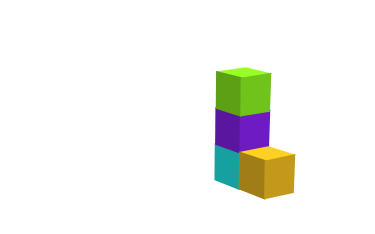

Given a shape , we use the term bent cavity in to refer to a set of connected points in contained inside of the minimum bounding box of , , but not contained within itself, such that it includes some points which can be reached by straight lines in beginning from points in , and some points which cannot be reached by straight lines in beginning from points in .

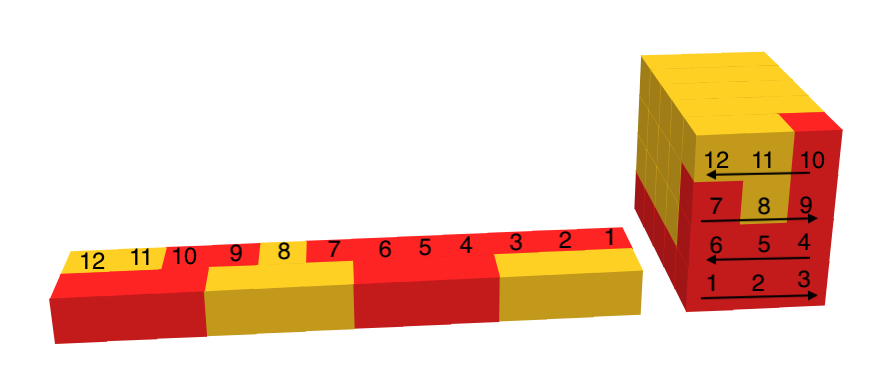

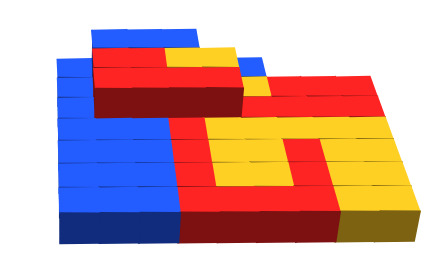

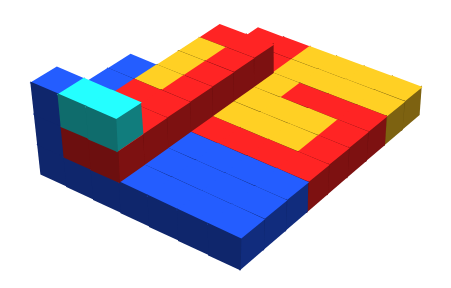

See Figure 2 for an example of a bent cavity.

Definition 2.6.

We define a shape encoding function as a function which, given as input an arbitrary shape , returns a unique finite set of binary strings, each unique for the shape , such that there exists a shape decoding function, and for all .

The shape encoding function we will define by construction in the proof of Lemma 3.2 will generate a set of binary strings for each input shape such that each string encodes the points of the shape starting from a different reference corner and rotation of a bounding box. That can lead to up to 24 unique binary strings (for 3 rotations of each of 8 corners) for most shapes, but less for those with symmetry.

Definition 2.7.

Given a shape and a point , we define the neighborhood of in to be the set . We also say that neighborhoods are equivalent up to rotation, so there is 1 neighborhood containing 1 point, 2 with 2 points, 2 with 3 points, 2 with 4 points, 1 with 5 points, and 1 with 6 points.

Definition 2.8.

We define a uniformly covered assembly as an assembly where every exposed side of every tile has the same strength 1 glue which is on. Additionally, if is the shape of , we require that for every 2 points with the same neighborhood, a tile of the same type is located in both locations and in .

A uniformly covered assembly has the same glue all over its surface, with no glues marking special or unique locations, and has the same tile type in each location with the same neighborhood, so such an assembly can convey no information specific to particular locations, orientation, etc.

Definition 2.9.

We define a deconstructable assembly as an assembly where (1) all neighboring tiles are bound to each other by one or more glues whose strengths sum to , and (2) each tile contains the glue(s) and signal(s) necessary to allow for all glues binding it to its neighbors to be turned off.

In the following definitions, we will use the term junk assembly to refer to an assembly that is not a “desired product” of a system, but which is a small assembly composed of tiles which were used to facilitate the construction but are now terminal and cannot interact any further.

Definition 2.10 (Universal shape encoder).

Let be the set of all finite shapes, let be a shape encoding function, let be a constant, and let be a tileset in the STAMR. If, for every finite subset of shapes , there exists an STAMR system , where consists of infinite copies of assemblies of each shape and also infinite copies of the singleton tiles from , such that (1) for every shape there exists at least one binary string and there exist infinite terminal assemblies of that contain glues in the on state on the exterior surfaces of those assemblies that encode (which we refer to as an assembly encoding ), (2) every terminal assembly is either an assembly encoding some or a “junk assembly” whose size is bounded by , and (3) no non-terminal assembly grows without bound, then we say that is a universal shape encoder with respect to .

Definition 2.11 (Universal shape decoder).

Let be the set of all finite shapes, let be a shape encoding function, let be a constant, and let be a tileset in the STAMR. If, for every finite subset of shapes , there exists an STAMR system , where consists of infinite copies of assemblies each of which encode a shape with respect to , and also infinite copies of the singleton tiles from , such that (1) for every shape there exist infinite terminal assemblies of shape , (2) every terminal assembly is either an assembly of the shape of some or a “junk assembly” whose size is bounded by , and (3) no non-terminal assembly grows without bound, then we say that is a universal shape decoder with respect to .

Definition 2.12 (Universal shape replicator).

Let be the set of all finite shapes and let be a tileset in the STAMR, and let be a constant. If, for every finite subset of shapes , there exists an STAMR system , where consists of infinite copies of assemblies of each shape and also infinite copies of the singleton tiles from , such that (1) for every shape there exist infinite terminal assemblies of shape , (2) every terminal assembly is either an assembly of the shape of some or a “junk assembly” whose size is bounded by , (3) the number of assemblies of each shape grows infinitely, and (4) no non-terminal assembly grows without bound, then we say that is a universal shape replicator.

2.2 STAMR Gadgets and Tools

Throughout our results we repeatedly make use of several small assemblies of tiles, referred to as gadgets, and patterns of signal activations to accomplish tasks such as keeping track of state, removing specific tiles, and passing information across an assembly. In this section we describe several of these gadgets and signal patterns so that they can later be referenced during our construction. We intend that this section also serve as a basic introduction by example to the dynamics of signal tile assembly.

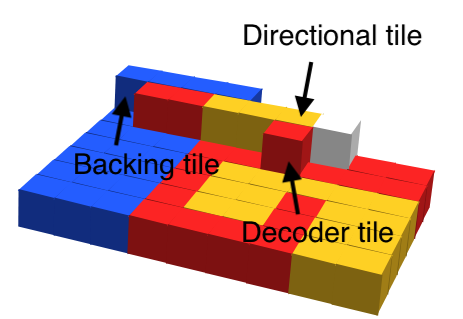

Detector Gadgets

Detector gadgets are used to detect when a specific set of tiles exist in a particular configuration relative to one another in an assembly. For a detector gadget to work, the tiles to be detected need to each be presenting a glue unique to the configuration to be detected. The strength of these glues should add to at least the binding threshold , but the total strength of any proper subset of the glues should not. If two or more tiles then exist in the configuration expected by the detector gadget, the gadget can cooperatively bind with the relevant glues. Upon binding, any signals with the newly bonded glues as a source will fire. These signals can be in the “detected tiles” or in the detector itself and can be used to initiate some other process based on the condition that the tiles exist in the specified configuration. More often than not, it’s also desirable for signals within the detector gadget to deactivate its own glues so that it does not remain attached to the assembly after the detection has occurred.

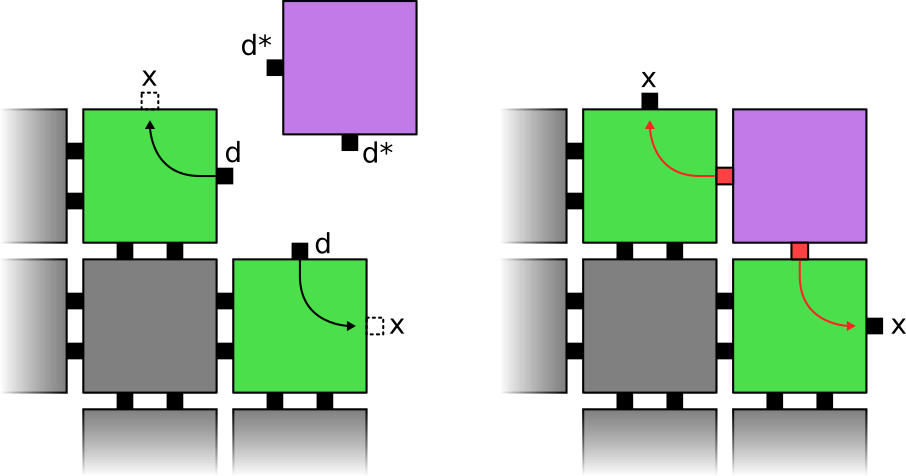

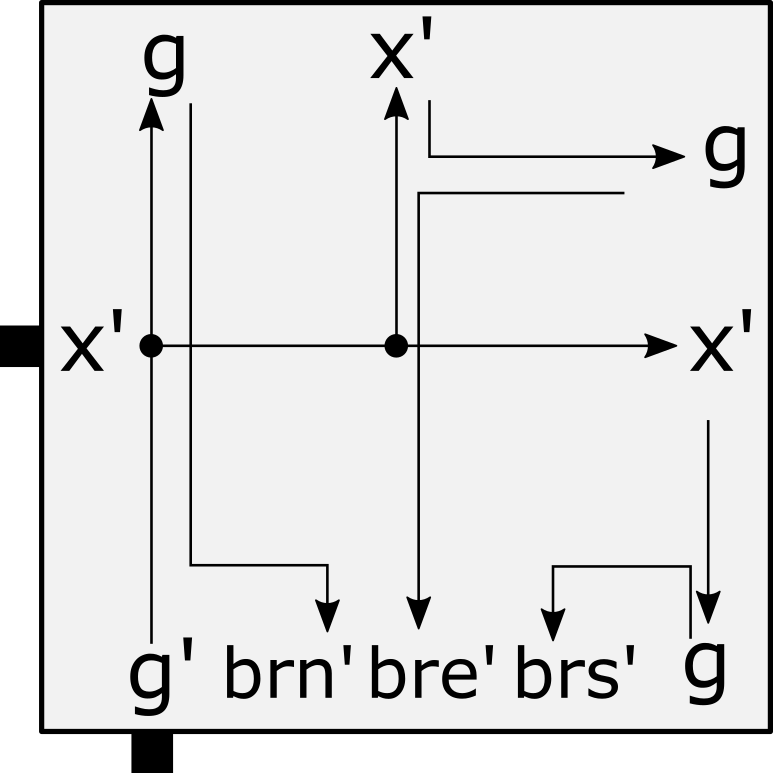

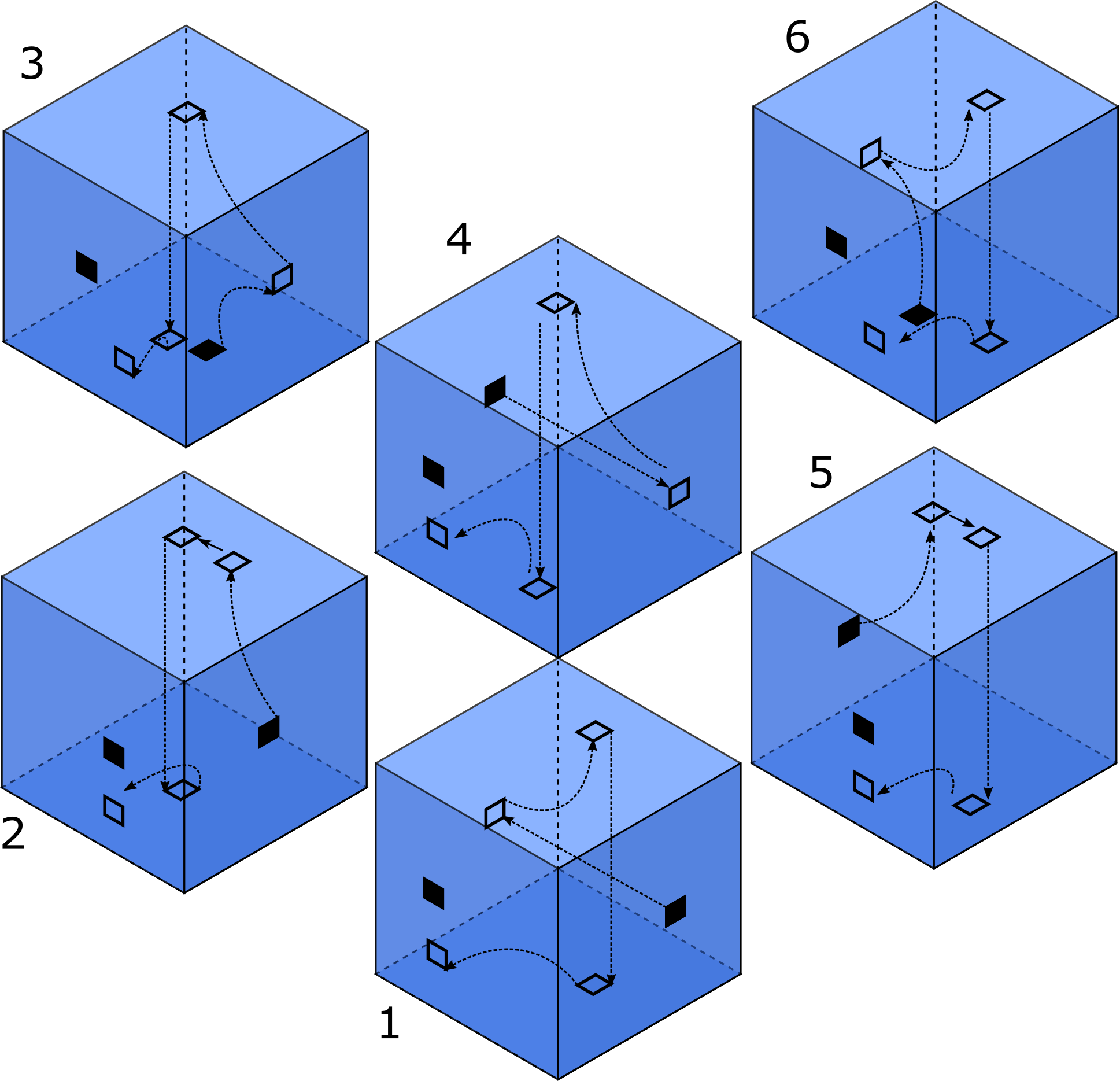

Detector gadgets can exist in many forms depending on the configuration to detect, but the most simple is a single tile. Illustrated in Figure 3 is a simple detector gadget designed to detect 2 diagonally adjacent tiles, each presenting a strength-1 glue of type towards a shared adjacent empty tile location. In this case, and the detected tiles are designed to activate their glues upon a successful detection. In general, detector gadgets can be made up of more than 1 tile. Duples of tiles can be used for instance to detect immediately adjacent tiles each presenting some specific glue on the same side. For detector gadgets consisting of more than 1 tile, the component tiles must be designed to have unique -strength glues between them so that the components can bind together piece-wise to form the whole gadget. Because all of the glues presented for the detection are needed to reach a cumulative strength of , only after it is fully formed will it be able to detect tiles and thus partially assembled detector gadgets will not erroneously perform partial detections. It is assumed in our results that signals within a detector gadget itself will cause the gadget to dissolve after a detection.

Corner Gadgets

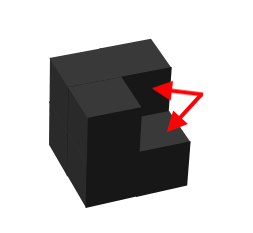

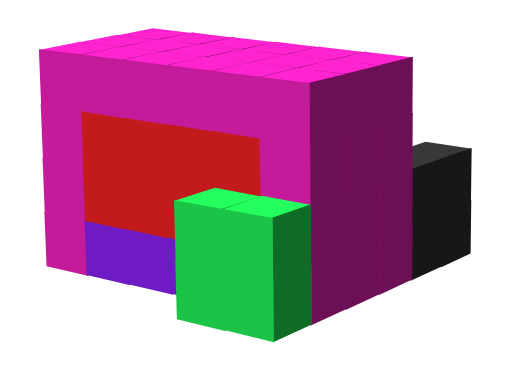

Corner gadgets are a specific type of detector gadget which are used primarily for facilitating the attachment of other tiles on the surface of some assembly. Corner gadgets can either be 2D, consisting of 3 tiles arranged in a square with one corner missing, or 3D, consisting of 7 tiles arranged in a cube with one of the corners missing. Because of this shape, a corner gadget is able to cooperatively bind to any single tile of an assembly with 2 accessible, adjacent faces. These faces must be presenting specified glues whose cumulative strength is at least , but neither individually is. Illustrated in Figure 4 is the side view of a 2D corner gadget attaching to an assembly. After the attachment, it is then possible for additional tiles to cooperatively bind along the surface of the assembly. This behavior is useful for initiating the growth of shells of tiles around an assembly as will be seen in our later construction.

Like with detector gadgets, signals fired from the binding of a corner gadget can also be used to initiate other tasks, though special care needs to be taken for 3D corner gadgets when . Because a 3D corner gadget has 3 interior faces which can have glues to bind with a tile on the corner of an assembly, it is often desirable to fire signals from all 3 of these glues; however, because only 2 glues are necessary to meet the binding threshold when , the third may not form a bond immediately. If it is planned for the corner gadget to eventually detach, then it is crucial that any signals causing the corner gadget to detach cannot fire until all 3 of the interior glues have first bound. This can often be accomplished using sequential signaling as described below.

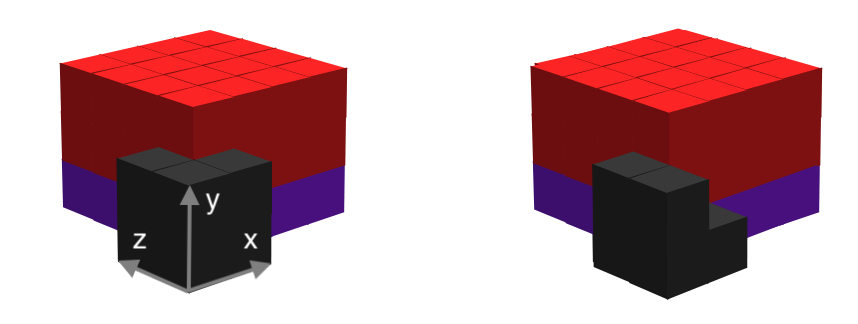

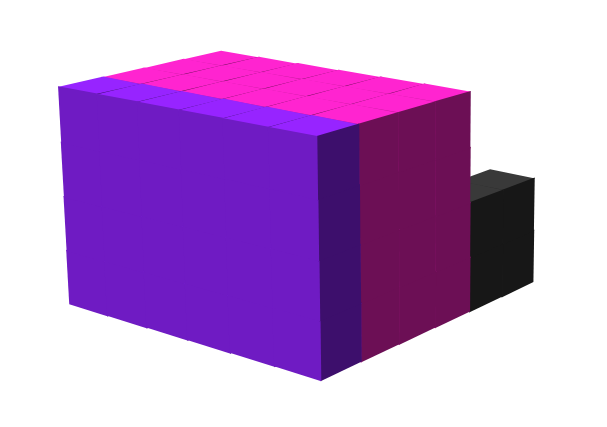

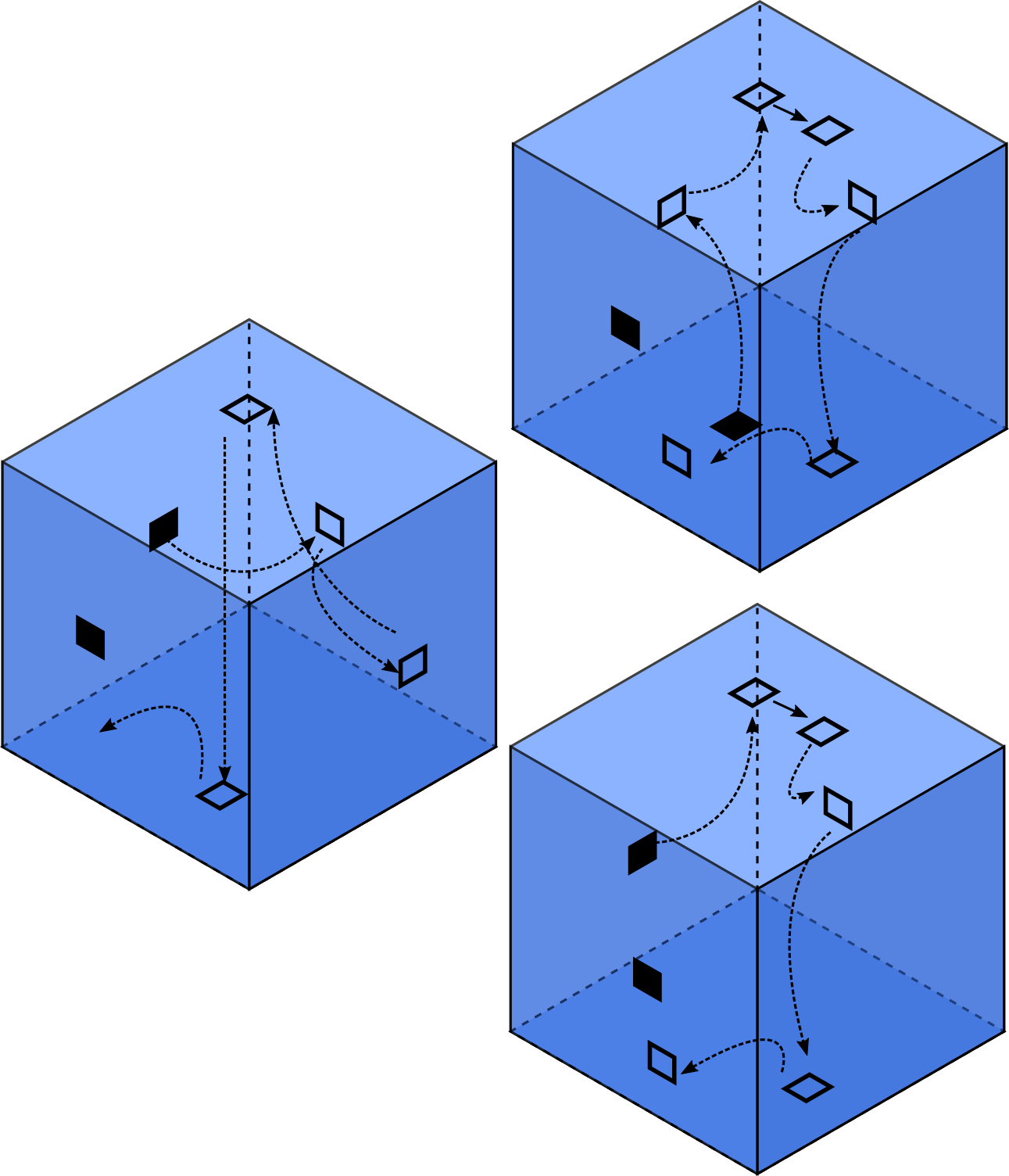

Sequential Signaling

By carefully adding additional helper glues and signals to a tile or tiles, we can ensure that signals in our tiles are fired in a specific order or ensure that a certain set of glues has successfully bound before certain signals are fired. The way in which this is done depends on the exact situation, but as an example consider the situation illustrated in Figure 5. In this situation we want the green tile to cooperatively bind to the assembly via glues of type and . Once this happens, we want to first activate additional glues of type and between the green tile and assembly so that each side of the green tile is attached to the assembly with strength 2, then we want glues of type on the other sides of the green tile to activate. The arrangement of signals illustrated in Figure 5 guarantees that the glues cannot activate before both the and glues do, since the signals which activate the glues are dependent on the glues and . A similar arrangement of signals and glues is used to implement gadgets called filler tiles in our construction.

Tile Conversion

It is often useful for tiles to change behavior after receiving a specific signal. This can be done by having signals activate a new set of glues on the tile and deactivate old ones. This can be thought of as converting the tile into a different type of tile, but it’s important to note that this process cannot happen indefinitely nor arbitrarily. Every tile conversion has to be prepared in the signals and latent glues of the tile and once those signals fire, they cannot fire again. It is possible for a tile to convert to another several times, but such a tile must have the necessary glues and signals for each conversion separately. It is also often possible achieve this behavior by detachment of one tile and attachment of another in the same location, though special care needs to be taken so that no other tiles can attach in the location during the conversion.

Tile Dissolving

For any arbitrary set of glues on a tile, we use the term dissolving to refer to the process of initiating signals which turn all possible glues to the off state (Figure 6). We note that due to the asynchronous nature of the model that no guarantee can be made with regards to the order of the processing of the signals. Tiles break apart from their supertile once a strength bond no longer exists between itself and its neighbor tiles. However other glues may be active when the tile does so, leading to the possibility of undesired binding due to exposed glues which are in the on state with a pending off signal.

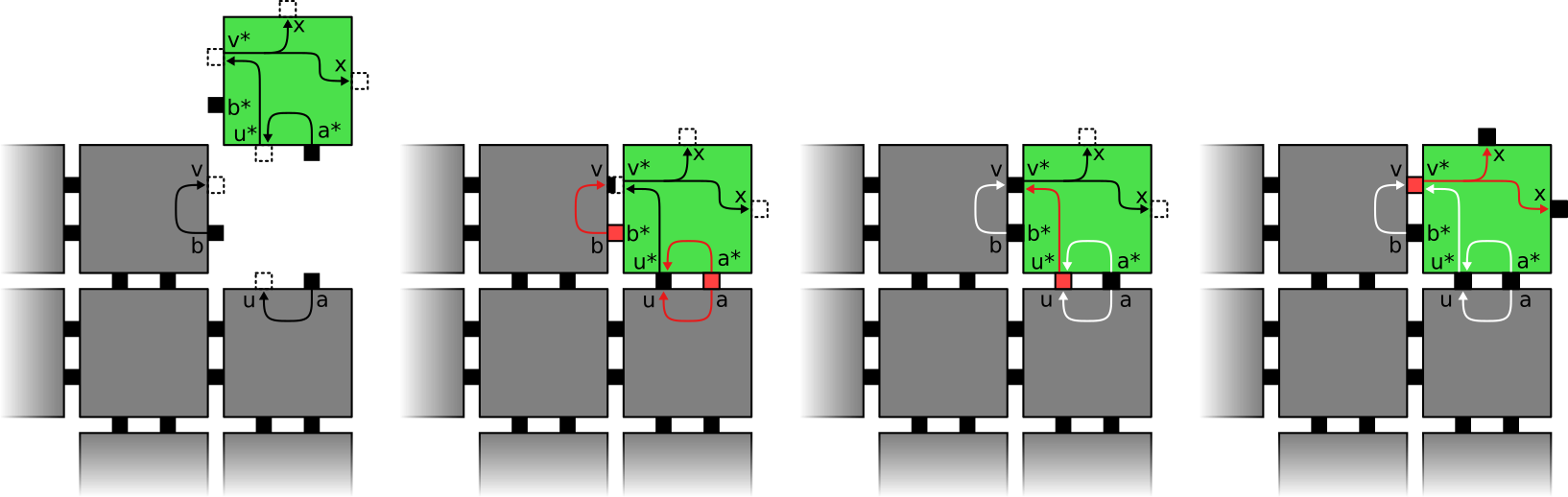

Message Following

We show how to pass a message through a sequence of tiles such that after the message has been passed, a second message can be passed through the exact same sequence of tiles in the same order. For example, signals propagate a message through a sequence of tiles (not necessarily distinct). We then propagate a message through a series of glue activations such that this message follows the sequence of tiles in that order. In this case, we say that the message follows the message.

Figure 7(a) shows a message being passed through a tile. Let denote this tile. This message enters from the south and then may potentially be output through the north, east, or south depending on if collisions occur. The goal is to ensure that a second message can be output through exactly that same side (and no others). Other cases where the message enters through the north, east, or west are equivalent up to rotation. For each possible output signal of the glue in , we define glues on the signal input side of the which are activated by the output glue being bound. As shown in Figure 7(a), the north glue activates , the east glue activates , and the south glue activates . Informally, the activated , , or glue “records” the output side of the message. In the case shown in Figure 7(a) where the message enters from the south, the , , and glues are sufficient for recording the output side of the message. In cases where the message enters through the north, east, or west, a glues is required to record the case where the message exits through the west side of a tile. The signal is then propagated using , , , and glues. Figure 7(b) depicts the signals and glues for propagating the signal in the case where the message enters from the south. In this case the signal will also enter from the south. The signal is propagated through as exactly one of the , , and glues binds to one of the , , and glues on the output side of a tile to the south of that is propagating . All of the , , and glues must be activated as the tile to the south of has no ability to know which direction the message of will take. The signal passed to will have the same output side as the signal. For example, if the message enters from the south and exits through the east, then, as shown in Figure 7(a), the glue will be activated; and will remain latent. Then, as the signal propagates through the tile to the south of , , , and are all activated on the north side of the tile. When and the glue on the south edge of bind, this binding event activates the glues , , and on the east edge of , effectively propagating the signal to the tile to the east of . This is shown in Figure 7(b). Notice that there are no signals belonging to that fire when binds. This is because no signals are needed to propagate to the south of . The binding of and are enough to propagate to the south of .

3 3D Shape Replication

In this section, we show that there is a tileset in the STAMR which is capable of replicating arbitrary shapes. This is stated in Theorem 3.1, and we prove it by providing modular constructions capable of encoding and decoding arbitrary sets of shapes which are given by Lemma 3.2 and Lemma 3.3, respectively, and then discussing how they can be combined to replicate shapes.

Theorem 3.1.

There exists a tileset in the STAMR which is a universal shape replicator, such that for the systems using (1) all input assemblies are uniformly covered, (2) the constant which bounds the size of the junk assemblies equals 4, and (3) they finitely complete with respect to a set of terminal assemblies with the same shapes as the input assemblies.

Lemma 3.2.

There exist a shape encoding function , and a tileset in the STAMR which is a universal shape encoder with respect to , such that for the systems using (1) all input assemblies are uniformly covered, (2) the constant which bounds the size of the junk assemblies equals 4, and (3) they finitely complete with respect to a set of terminal assemblies which encode the shapes of the input assemblies.

Lemma 3.3.

There exist a shape decoding function , and a tileset in the STAMR which is a universal shape decoder with respect to , such that for the systems using (1) the constant which bounds the size of the junk assemblies equals 3 and (2) they finitely complete with respect to a set of terminal assemblies with the same shapes as those encoded by the input assemblies.

We now prove Lemmas 3.2 and 3.3, and consequently Theorem 3.1, by construction. In the following few sections we describe the process by which an STAMR system can encode arbitrary shapes. We then show how an STAMR system can construct arbitrarily shaped assemblies from the encodings produced by the encoding system. Additionally, these systems make use of universal tilesets and respectively, meaning that regardless of the shapes to be encoded or decoded, our systems never require additional tiles besides those from and . These tilesets can then be combined to create a tileset which is then a universal shape replicator. It should also be noted that constructing the universal encoder and decoder separately allows for additional complex tasks to be performed in the STAMR. For example, tiles are capable of simulating the execution of Turing machines to perform arbitrary computation. As will be briefly discussed later, this means that once shapes have been encoded, it is then possible to manipulate the encodings using simulated Turing machines before the decoding process. Such behavior is clearly much more general than shape replication.

3.1 Forming a bounding box and electing a corner as “leader”

Here we describe the process by which a set of arbitrary shapes can be encoded in the STAMR using a universal tileset . It should be noted that we don’t explicitly list each tile type in ; rather, much like how it is more useful to use pseudo-code instead of compiled machine code when describing an algorithm, we describe the tiles in implicitly by their functionality, noting that there are many essentially equivalent ways to design tiles which perform the necessary tasks and a discussion of the finer details regarding exactly which signals and glue types are used in each instance would be less informative.

Given our set of shapes, we define our STAMR system to be the triple where is our initial system state containing assemblies of the shapes in . This state consists of all tiles in , each with an infinite count, and additionally consists of a set of uniformly covered, deconstructable assemblies such that the shape of is for . The assemblies of are called our shape assemblies and are made only of tiles from a fixed subset of called shape tiles. Note that the glues and signals defined in these shape tiles are not used to encode any information regarding the structure of our shape assemblies; any shape specific information is inferred during the encoding process and the shape tiles simply contain the necessary glues and signals to perform basic tasks required for the encoding process, none of which are specific to any particular part of the shape assemblies. Additionally, we will define tile encoding and decoding functions, and during our construction. Essentially our encoding of a shape consists of a sequence of rows of binary values, each row corresponding to a 1-dimensional slice within the minimal bounding box of our shape, with representing a location in the shape and representing a location not in the shape.

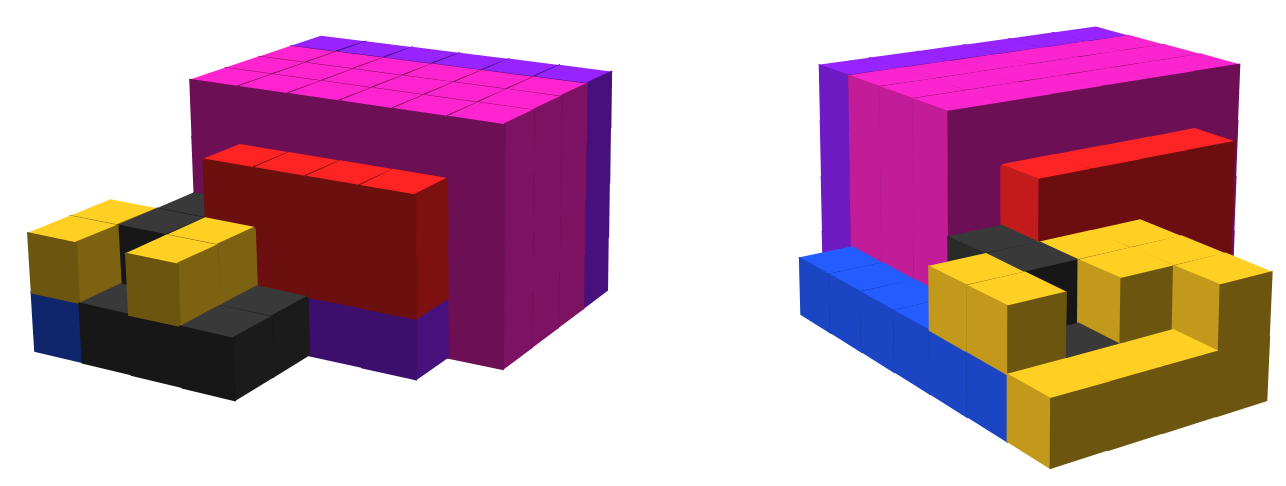

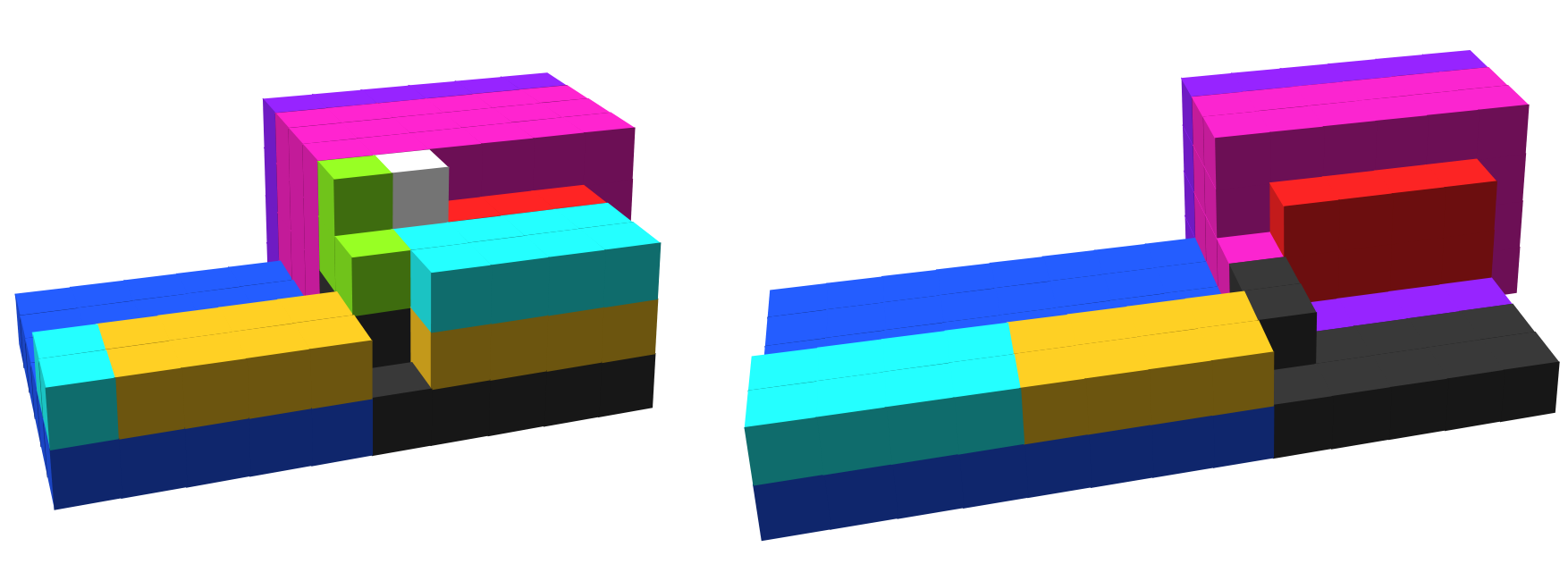

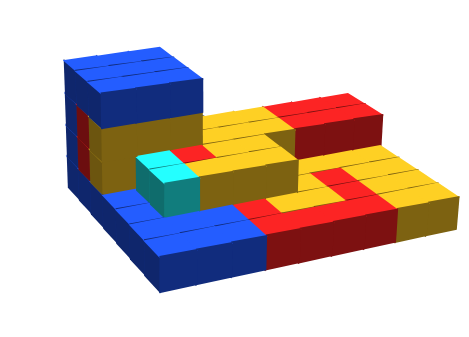

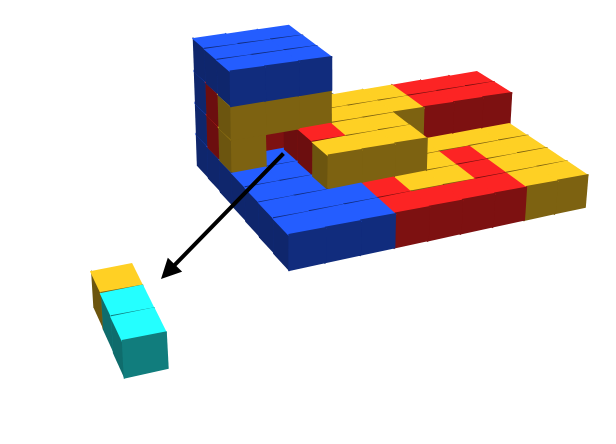

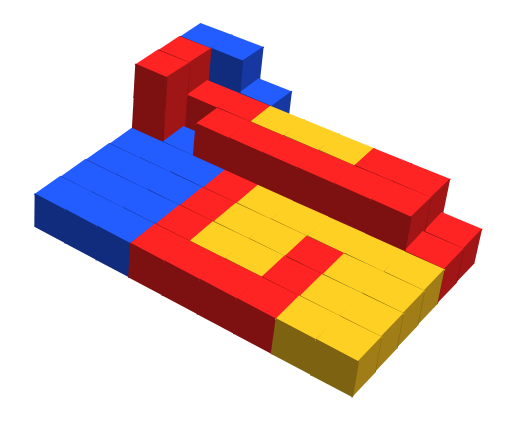

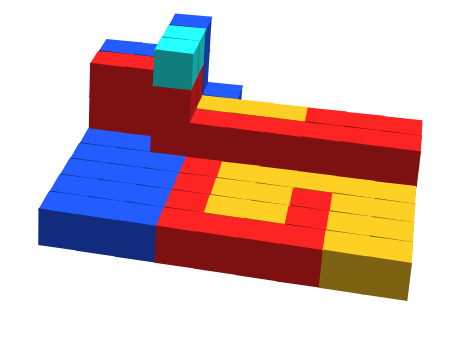

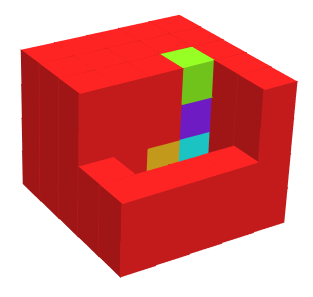

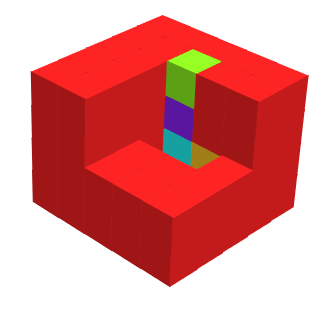

The encoding process described below can be largely broken down into 3 steps. First, a bounding box is constructed around the shape assemblies using special tiles which are distinct from the shape tiles. Then, one of the corners of the box is elected non-deterministically to be the leader corner to provide an origin point which will represent the first tile location of our encoding. Finally, from the leader corner, the shape will be disassembled tile-by-tile during which an encoding assembly will be constructed, recording for each disassembled tile whether it is part of the shape or not (i.e. a “filler” tile used to assist the construction). During our description of the encoding process, we will follow the process for a single shape assembly , but note that all shape assemblies are encoded simultaneously in parallel in .

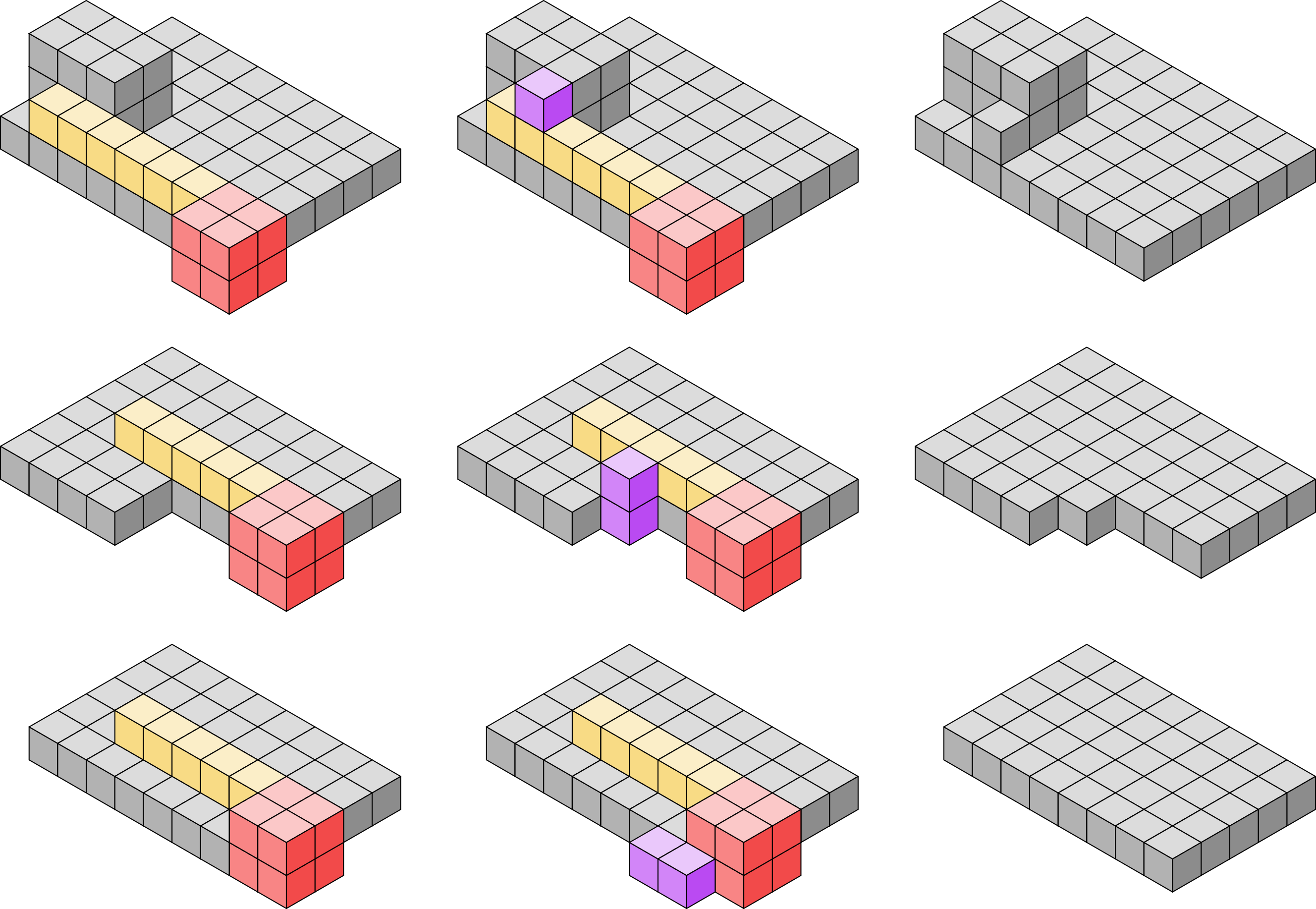

3.1.1 Bounding Box Assembly Construction

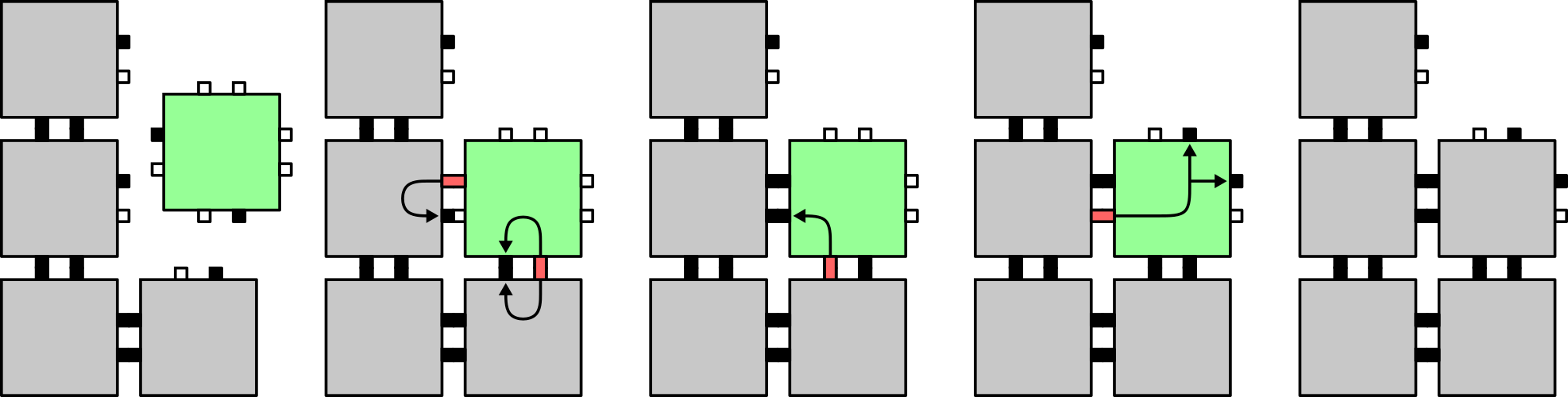

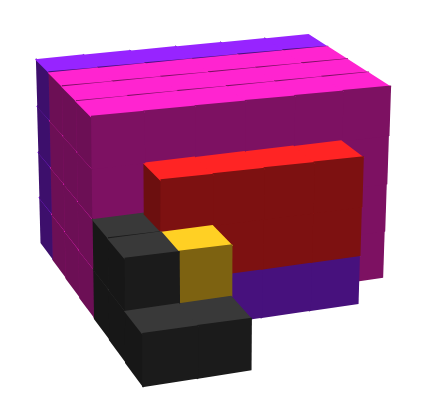

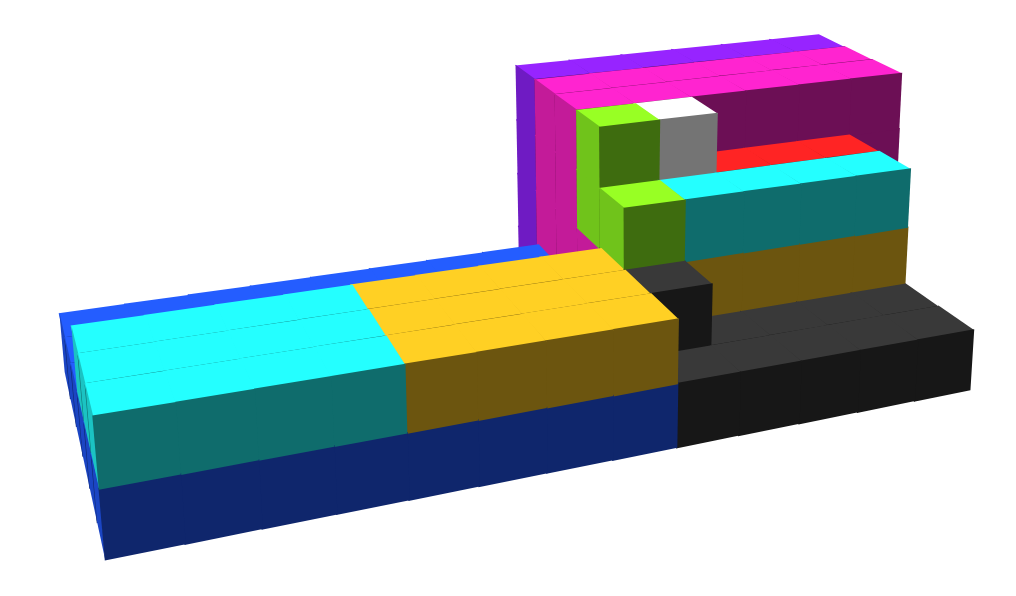

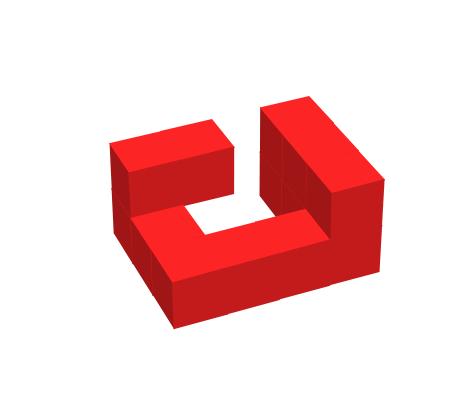

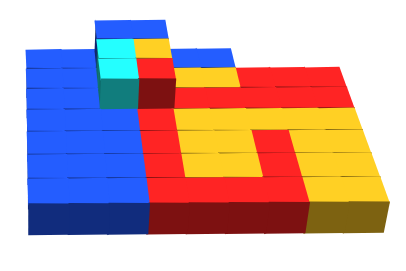

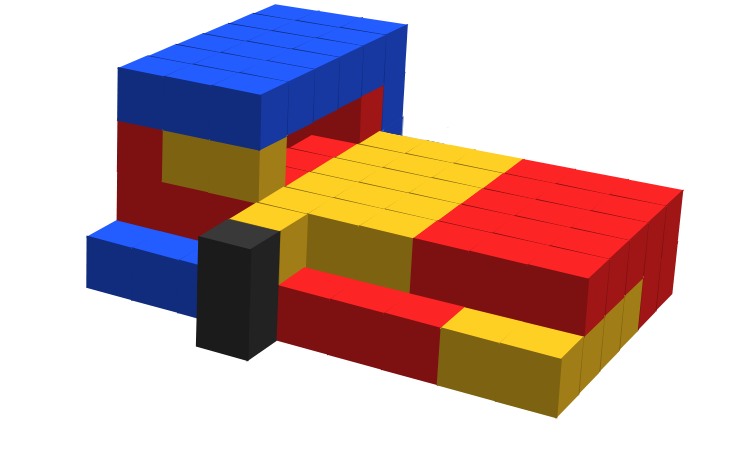

The first step in our encoding process begins by forming a bounding box assembly through the attachment of special tiles, called filler tiles, to . These filler tiles cooperatively bind to 2 diagonally adjacent tiles of our shape assembly in order to fill out any concave portions. When a filler tile attaches to an assembly, signals are fired from the newly bound glues which activate additional glues between the filler tile and shape assembly. These new glues ensure that the filler tile is bound with strength 2 on each face to the shape assembly as this will be important during the disassembly process. After the filler tile is firmly attached with 2 strength-2 bonds, signals are then fired within the filler tile which activate strength-1 glues of type on all other faces. These will be used for further filler tile attachment. Figure 8 illustrates the attachment of a filler tile to an assembly and shows how sequential signaling is used to ensure that the filler tile is attached with strength 2 on both of its input faces before activating glues on each of its output faces.

Because filler tiles must be able to cooperatively bind to both shape tiles and other previously attached filler tiles, we need 3 unique types of filler tiles: One which initially presents 2 glues of type to bind with 2 shape tiles, one which initially presents 2 glues of type to bind with 2 other filler tiles, and one which presents one of each glue to cooperatively bind with a shape tile and a filler tile. Each type of filler tile is otherwise identical. Because we’ve chosen our binding threshold , the two initially present glues are sufficient for binding into any location on the assembly with at least 2 adjacent shape or filler tiles. The signals from the binding of these glues then activates additional glues on the same faces which ensures that the filler tile is attached with strength 2 on two separate faces, regardless of whether or not additional filler tiles later bind to this one. This property will be used to guarantee that the assembly stays connected during the disassembly process.

Eventually, after sufficiently many filler tiles have attached, there will be no more locations in which another filler tile can attach. There are often many ways in which this can occur for any shape assembly, but the resulting bounding box assembly will always be a minimal bounding box of our shape. It should be noted that its possible that not every location within the bounding box is filled. This can occur if the original shape had enclosed cavities, but can also occur because the attachment of filler tiles can create additional cavities as they attach. This is not a problem and it will always be possible for filler tiles to complete the outer surface of the bounding box. Additionally, this bounding box will be uniformly covered by glues of type and .

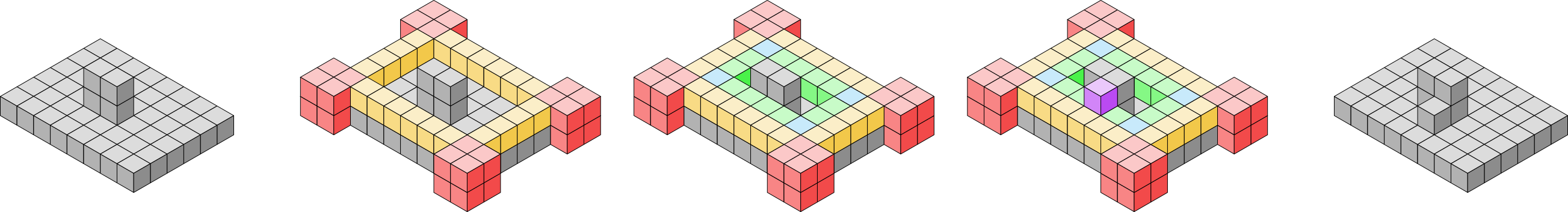

3.1.2 Detecting Bounding Box Completion

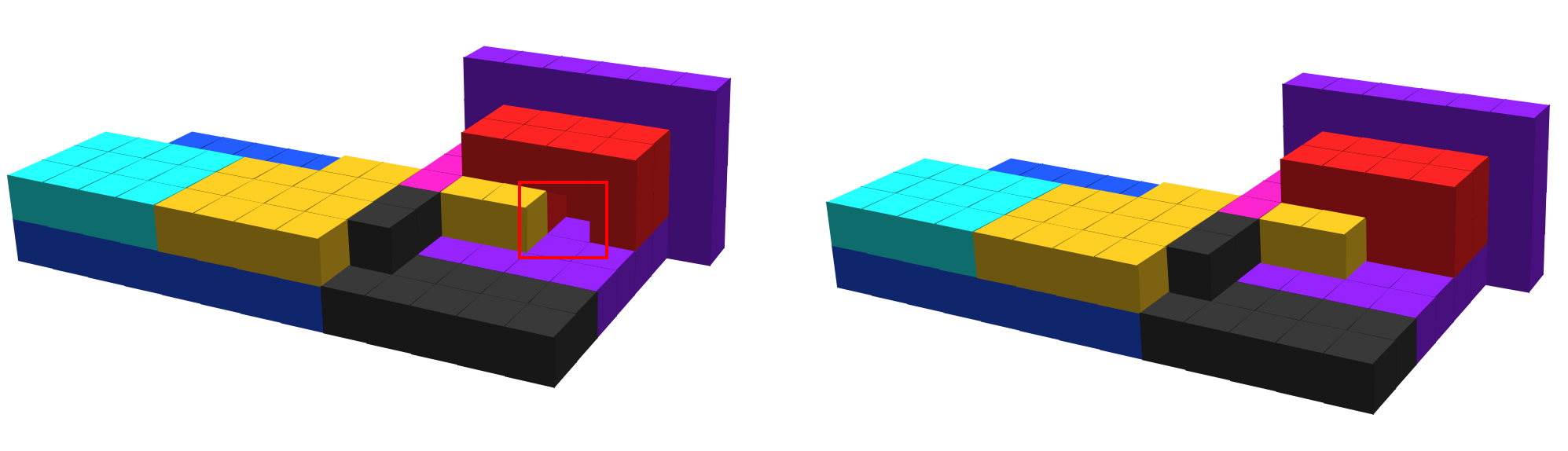

In order to continue with the encoding process, we first need to verify that the bounding box is fully formed. This is done by growing a shell of tiles around our assembly. This shell, which we call the inner shell, is able to grow to completion only if the assembly is a fully formed bounding box. Figure 9 illustrates the high-level construction of the inner shell around a fully formed bounding box.

Growth of the inner shell begins with the attachment of corner gadgets to our assembly. We use 2 types of 3D corner gadgets, one which is able to bind to a corner of our assembly presenting 3 glues of type and one which is able to bind to a corner presenting 3 glues of type (note that at only two glues are needed for a corner gadget to attach, but any tile allowing a corner gadget to attach must expose all 3). That is, the corner gadgets can attach either to a shape tile or a filler tile on a corner of our assembly. Note that these gadgets exist in our system while the bounding box is being constructed; therefore, it’s possible that corner gadgets attach to tiles in our assembly before the bounding box has been fully constructed. Additionally, special care needs to be taken when the bounding box surrounding our shape assembly has at least one side of dimension 1. The details of the inner shell’s construction is described below and these various cases are addressed.

When a corner gadget attaches to our assembly, signals from the attachment cause strength-1 glues to activate on the faces of the corner gadget which point parallel to the surface of our assembly. These glues will be used to allow cooperative attachment of special edge tiles that will attach in a line along the edges of a completed bounding box. The glues activated on the corner gadget can either be of type or depending on which face of the corner gadget they reside. Glues of type indicate that the edge to be grown is a left edge of the bounding prism relative to the direction of growth of the edge while glues of type indicate a right edge.

Like filler tiles, edge tiles initially have 2 active glues on adjacent faces: one of these glues is either of type or so as to be complementary to the glue presented by the corner gadget, and one of type or so as to also be complementary to a glue on the surface of our assembly. Since any combination of these glues is necessary, there are 4 unique types of edge tiles. Once an edge tile has cooperatively attached to our assembly, signals are fired which activate another glue of type or to allow additional edge tiles to cooperatively attach to it and the assembly. Additionally, glues are activated on all other exposed sides of the edge tile which will be used by detector gadgets later. These glues are unique to the specific face of the edge tile so that detector gadgets can distinguish between the interior and exterior sides of an edge as well as the side of the edge tile pointing away from the assembly. Although tiles are allowed to rotate in the STAMR and don’t have fixed orientations, this directionality can be enforced by the relative orientations of the two glues used for the initial binding of a tile. Edge tiles will continue to grow along the surface of our assembly from corner gadgets until they are either blocked by another tile, reach the end of the surface of our assembly, or it is detected that the edge is invalid.

For an edge to be valid, there must be no shape or filler tiles adjacent to any edge tiles except for those underneath the edge tiles to which the edge tiles cooperatively attached; additionally, if an edge is a right (respectively, left) edge, then there must not be a shape or filler tile occupying a location diagonally adjacent to the right (resp., left) of the edge tiles making up the edge with respect to the forward growth direction of the edge. Edge tiles which violate these validity conditions can be easily detected using detector gadgets specific to the particular situation as illustrated in Figure 10. Following the attachment of such a detector gadget, a signal is propagated along the edge causing all connected edge tiles and corner gadgets to dissolve. Before this signal is propagated though, signals from the detector gadget ensure that a new filler tile is effectively added to the assembly in a safe location (that is without causing the eventual bounding box to be bigger than necessary). This is done using signals from the detector gadget to convert one of its own tiles or the detected invalid tile into a filler tile. This conversion is done so that we don’t risk infinite assembly sequences wherein a corner gadget attaches, attempts to grow an invalid edge, and dissolves repeatedly. Because a filler tile is always effectively added upon detection of an invalid edge, eventually it will be impossible for invalid edges to occur.

In the case where a valid edge is blocked by another tile, then there are 2 possibilities: (1) the edge is blocked by a shape or filler tile, or (2) the edge is blocked by another edge or corner gadget. If a filler tile blocks the path, then like with invalid edges, a detector gadget can cooperatively bind to the blocking tile and the edge tile, convert the edge tile into a filler tile, and propagate a dissolve signal down the remaining edge tiles. If another edge tile or corner gadget blocks the edge, then we need to determine if the blocking tile is part of a valid edge. If the edge is invalid, then it will eventually dissolve and nothing needs to be done. Otherwise, the tile blocking our edge belongs to another valid edge. In this case the meeting point can either be at a corner of our assembly or along the edge of our assembly. Because of the unique glues presented on all sides of an edge tile, these situations can easily be differentiated by detector gadgets. If the meeting point is a corner, then signals from the corresponding detector gadget will cause the corner to convert to a piece of a corner gadget. The remaining corner gadget pieces can then attach and the result will be a corner gadget connected to two incoming edges. If the meeting point is an edge, the detector gadget will fire signals to activate glues between the colliding edge tiles connecting the edge tiles and allowing future signals to propagate between them.

3.1.3 Dissolving Edge Tiles and Corner Gadgets

Care must be taken when dissolving edge tiles and corner gadgets to avoid erroneous attachments of tiles which have dissolved, but on which not all of the glues have yet deactivated. When dissolving edge and corner tiles, we use a procedure called careful dissolving to guarantee safe detachment. To understand this procedure first note that, we make a distinction between those glues which were initially active on a tile before it attached to an assembly, which we call prior glues, and those which activated after the initial attachment, called posterior glues. Here we make one exception regarding the strength 2 glues present between the outermost corner tile of a corner gadget and its 3 neighboring tiles, these are classified as corner glues and will be handled differently. Also, in addition to all of the functional glues present on an edge tile or corner gadget tile, when two edge tiles bind to each other, a strength 1 pair of glues of type and , called dissolve helper glues, are activated between them. Corner gadgets also have these glues activated between their tiles, but this is done in a tree-like structure with the root being the outermost corner tile. This tile shares dissolve helper glues with the 3 corner gadget tiles adjacent to it, and these share dissolve helper glues with the 3 corner gadget tiles which cooperatively bound in between, though only on 1 face each so as to form a tree.

Careful dissolving begins when a detector gadget binds to an edge or corner gadget tile. This binding initiates a dissolve signal that propagates along the edge and corner gadget tiles, deactivating all prior glues. Now suppose is a group of connected edge tiles which have detached from the assembly as a result of these deactivations. By our tile design, prior glues always only bind with with either posterior glues or bounding box glues ( or ), and posterior glues, which are always strength 1, only bind with prior glues. Notice that can be presenting at most 1 prior glue of strength 1, otherwise it would not have detached from the assembly, though it may have any number of posterior glues and some dissolve helper glues. Because attachment to an assembly requires either a prior glue of strength 2 or two prior glues of strength 2 to bind with posterior glues exposed by a bounding box assembly, is effectively inert. It is possible that two detached junk assemblies have dissolve helper tiles exposed, but any cooperation between these junk assemblies would require the cooperation of a dissolve helper glue and a prior/posterior glue pair to occur. This may happen, but eventually the prior glue will deactivate and the combined junk will dissolve.

By the connectivity offered by the dissolve helper tiles, even as further breaks up into smaller assemblies or individual tiles, this property is preserved, since in addition to the dissolve helper glues between each pair of tiles in , any glues holding tiles together form a prior/posterior pair. For a strength 1 cut to exist in , allowing it to break apart, it must be the case that the prior glue deactivates between the tiles, otherwise they will still be held together with at least strength 2. Eventually, we will be left with only individual inert tiles or the 4 tiles that make up the corner of a corner gadget which will also be inert by the same argument. Thus we have a maximum junk size of 4. Careful dissolving is possible so long as the above conditions regarding prior and posterior glues are met. This is true for all gadgets and tiles used during the leader election process, so during the leader election process, when we say that a dissolve signal is propagated, we mean that careful dissolving occurs between those tiles.

3.1.4 Filler Verification

When the edges growing from 2 corner gadgets meet via edge tiles between them along the surface of a bounding prism, signals between them through the edge tiles activate glues which allow a filler verification process to begin. This process proceeds in iterations growing inwards towards the surface’s center and verifies that there are no gaps or protrusions in the surface. If gaps are found, nothing happens until those gaps are filled with filler tiles, after which the verification continues. If protrusions are found, then as illustrated in Figure 11, detector gadgets are able to cooperatively bind with a verification tile and a shape/filler tile of the protrusion. Signals from this attachment cause the verification tile to become a filler tile and cause all other involved verification tiles, edge tiles, and corner gadgets to dissolve.

The filler verification procedure is as follows. When the edge between two corner gadgets is filled with edge tiles, a signal is able to propagate between the corner gadgets. Once a corner gadget has received signals from its 2 neighboring corner gadgets, glues are activated on the adjacent edge tiles allowing the cooperative binding of a tile called a verification corner tile. This verification corner tile attaches diagonally adjacent to the corner gadget within the region bounded by the edge tiles. Additionally, signals from the corner gadgets activate glues on the other edge tiles which allow special verification edge tiles to cooperatively bind with the edge tile and surface of the bounding prism. If there is a gap preventing such a binding, it will simply not occur until filler tiles attach to fill the gap. If there is a protrusion, a detector gadget will be able to cooperatively bind with a filler/shape tile on the protrusion and a verification tile. That verification tile will then convert to a filler tile through signals fired from the detector gadget and all other involved edge tiles, verification tiles, and corner gadgets will dissolve. If no protrusion is found, the process repeats with the verification corner tiles acting as the corner gadgets and verification edge tiles acting as the edge tiles. A new iteration of the verification process will begin in the next inner layer of the surface.

This process will continue until the center is reached. This can happen in 2 different ways depending on whether the shortest side of the surface is of even length or odd length. (See Figure 12.) If the shortest side of the surface is of even length, then eventually 2 verification corner tiles will be adjacent to each other. A duple detector gadget will be able to cooperatively bind with those tiles indicating that the center has been reached. This will happen on both pairs of adjacent corner verification tiles and once the verification edge tiles attach between them, signals will be able to propagate between the pairs of corner verification tiles. These signals will propagate back along the iterations of the verification tiles and activate glues on the corner gadgets which will allow for the growth of the outer shell to begin on this face of the bounding prism. If the shortest side of the surface is of odd length, the process is similar, but instead of 2 verification corner tiles being adjacent, there will be a single verification corner which is adjacent to either 2 verification corner tiles from the previous iteration, or all 4 if the surface of the bounding prism was a square. In either case, detection gadgets will be able to initiate signals which inform the corner gadgets that verification of this face is complete. Additionally, upon completion, a dissolve signal causes all glues on the verification tiles to turn off and the verification tiles themselves to dissolve.

3.1.5 Handling Thin Shapes

The process described above assumes thick shapes, those whose minimum bounding box has no sides of length 1. To handle thin shapes (i.e. those shapes that are not thick), first note that for every corner gadget attached to a thin shape, there will be at least one direction where no edge tile can cooperatively attach to the corner gadget and shape assembly. This can be detected by a detector gadget and upon detection signals will be fired accomplishing 2 tasks: (1) glues will be activated on the corner gadget which allow other corner gadget tiles to attach as if two mirrored corner gadgets were overlapping along the thin edge, and (2) edge tiles running along the thin edge of the assembly from the corner gadget will be dissolved and the outgoing or glue from the corner gadget will be deactivated and replaced by a newly activated glue of type . We call corner gadgets that have been modified in this way extended corner gadgets. To the glue of type , a different type of tile, called a thin edge tile, can cooperatively attach to the assembly and corner gadget. Thin edge tiles behave similarly to regular edge tiles and grow sequentially along the assembly. Upon meeting another thin edge tile, like with normal edge tiles, a detector gadget cooperatively binds and activates glues on the thin edge tiles allowing them to bind with each other if they meet along a thin edge or converting the thin edge tiles into corner gadget tiles if they met at a corner. If the path of the thin edge tiles is blocked by a shape or filler tile, a detector gadget can cooperatively bind and the last thin edge tile is converted to a filler tile and a dissolve signal is propagated down the remaining edge tiles.

In the case where our initial shape assembly is a thin rod, having dimensions , the corner gadgets which bind to the ends of the ends of the rod will be extended twice (or 3 times if ). Detector gadgets can be used to determine that a corner gadget has been extended more than once and signals from the attachment of these detector gadgets will activate the same glues on the corner gadgets indicating that filler verification is complete for the corresponding side of the assembly.

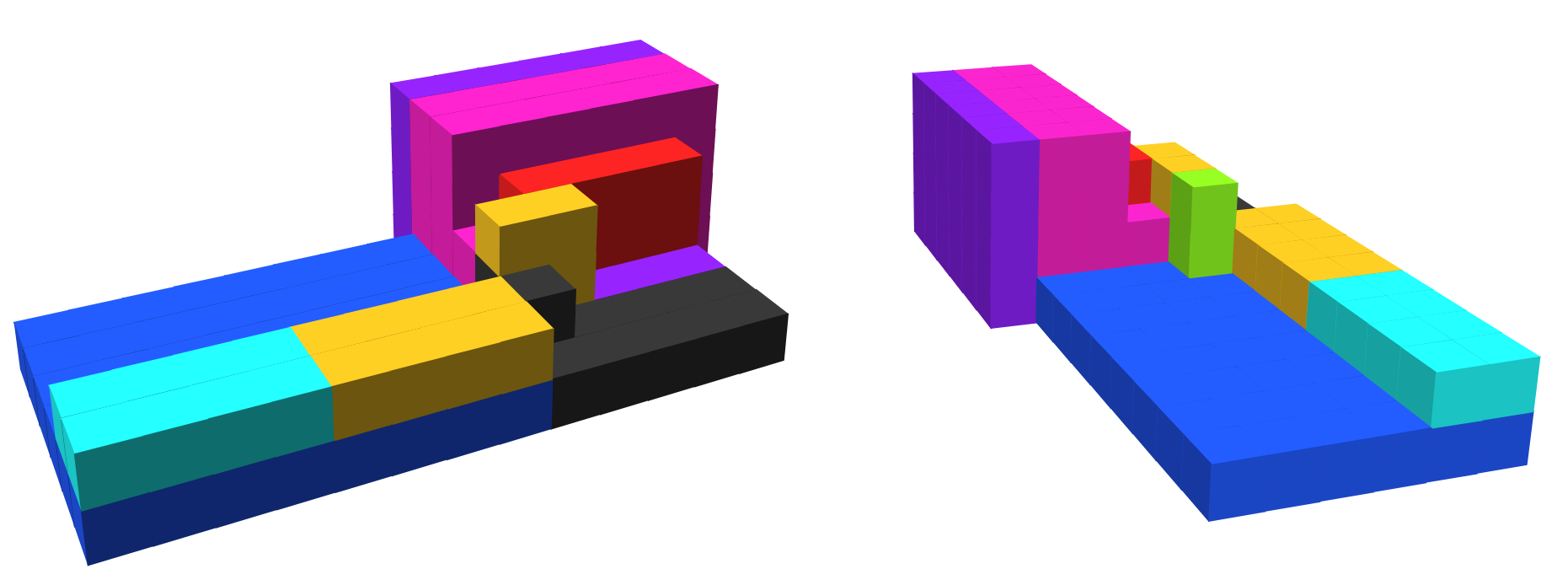

3.1.6 Outer Shell Construction

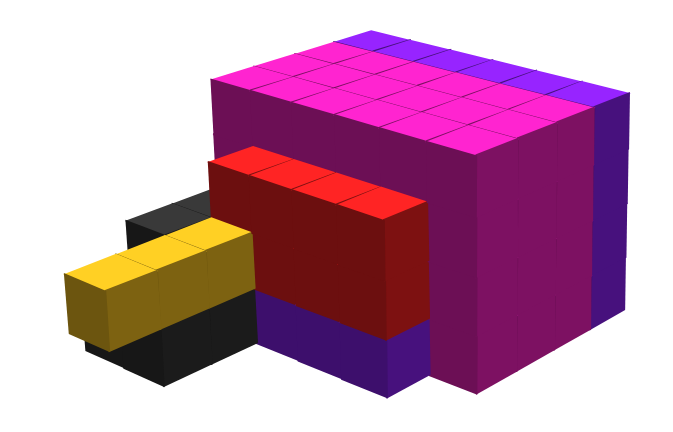

Whenever the filler verification process is completed on a surface of the bounding prism, signals activate glues on the corner gadgets of that surface which initiate the growth of an outer shell. The glues activated on the corner gadgets exist on the outward pointing faces of the tiles between edge tiles and allow tiles called outer shell tiles to bind with strength 2 to these locations as illustrated in Figure 13. Once attached, these outer shell tiles present strength-1 glues of type on all sides except the one that points away from the assembly. Another type of tile, called an outer edge tile, is then able to cooperatively bind to these outer shell tiles and the edge tiles from the inner shell. These outer edge tiles also present glues which further allow other outer edge tiles to cooperatively bind on top of the edge tiles from the inner shell. When two outer edge tiles meet along an edge, detector gadgets can cooperatively bind to the pair causing them to activate glues between each other and bind.

Additionally, special corner gadgets called outer corner gadgets bind with 3 outer shell tiles on the corners of the assembly. (Because in our construction , outer corner gadgets really only cooperatively bind with 2 of the outer shell tiles to attach, but by using sequential signaling, we can ensure that they do not propagate their signals to other outer corner gadgets until they are bound to all 3 outer shell tiles on their respective corner of the assembly.) These outer corner gadgets are different from normal corner gadgets in that they have 12 tiles as illustrated in Figure 13. Once an outer corner gadget attaches, signals are propagated along outer shell and outer edge tiles to adjacent outer corner gadgets.

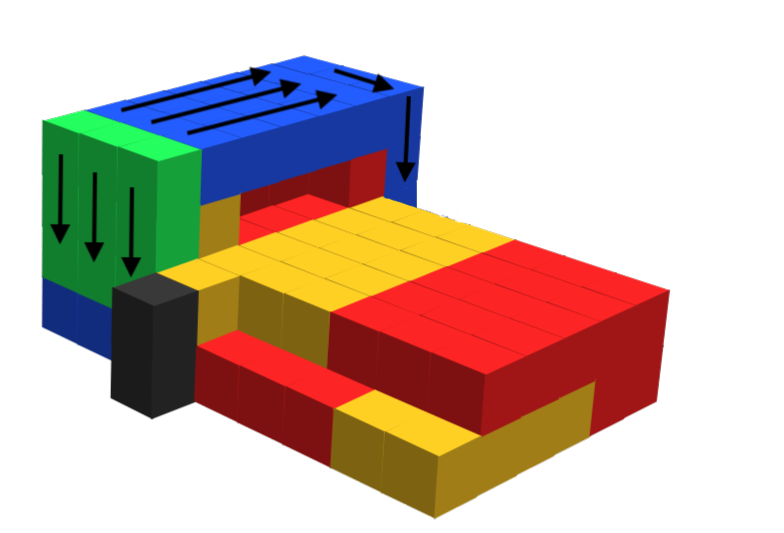

When an outer corner gadget has received this signal from all 3 of its neighbor outer corner gadgets, a dissolve signal is propagated to the inner shell corner gadget below. This signal prompts that corner gadget and its edge tiles (but not any other corner gadgets) to dissolve and additionally causes glues, called candidate glues, of type to activate on the corners of the bounding box assembly underneath and glues of a complementary type to activate on the interior corners of the outer corner gadgets. Because of the condition under which these signals are fired, an outer corner gadget will not signal its underlying inner shell corner gadget to dissolve until all of the outer shell corner gadgets neighbors are bound to the assembly. Consequently, even though the outer shell gadgets cause the inner shell between them and the assembly to dissolve, the outer shell will remain attached to the assembly on at least one corner until all outer corner gadgets have attached. Once the final outer corner gadget attaches however, the inner shell underneath will be able to fully dissolve and we will be left with our bounding box enclosed within but not attached to the outer shell. While the bounding box will be free to move (slightly) within the outer shell, it will be trapped inside of it due to their relative sizes.

Because the corners of the bounding box and interior corners of the outer shell have complementary glues, the corners of the bounding box assembly are able to bind to the interior corners of the outer shell; however, because the interior of the outer shell is larger than the bounding box itself, only 1 corner will be able to touch the outer shell at any given time, and thus to bind. The corner of the bounding box which happens to bind is elected leader and a special glue on that corner is activated. Additionally, the binding of the bounding box assembly to the outer shell causes signals to propagate which cause the glues on the outer shell to deactivate and then cause the outer shell to dissolve. We are then left with a bounding box with 1 corner “elected as leader” and containing a glue from which the disassembly process can begin.

3.2 Shape encoding

Following the process of leader election on a bounding box, we are presented with a single corner with unique glues exposed indicating a leader tile. Here we describe the tiles of which allow for the the universal shape encoding function to be implemented on the shape contained in a bounding box. We use the term voxels to reference the locations of in the bounding box, which may contain shape tiles, filler tiles, or no tiles as there may still be cavities within the box.

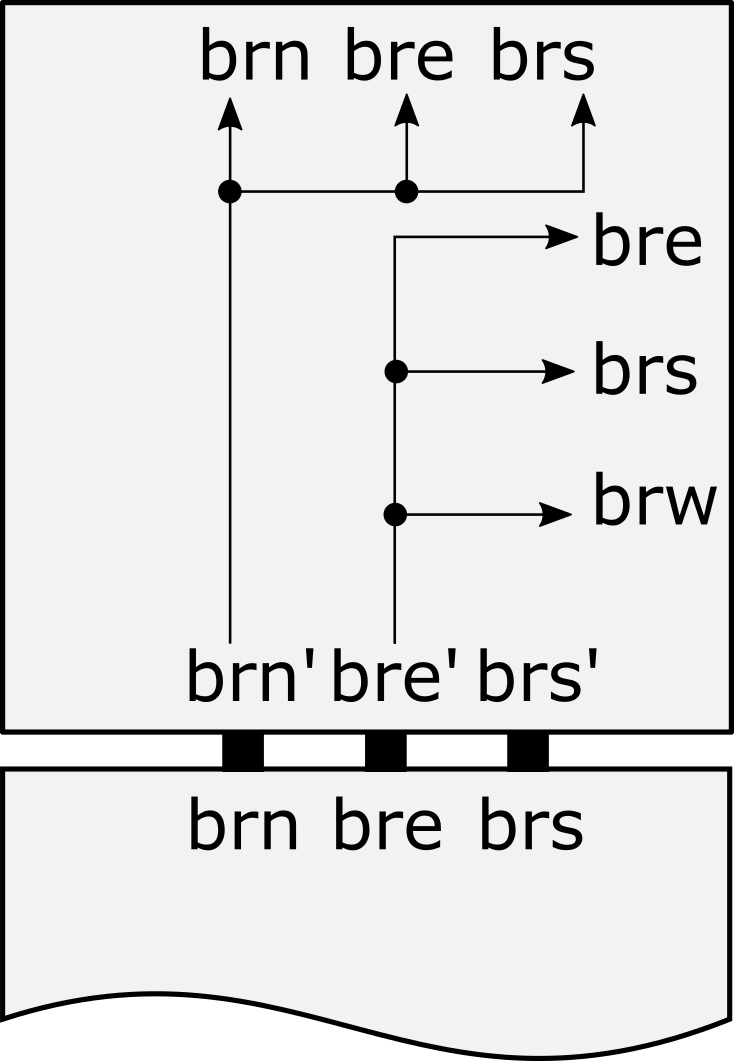

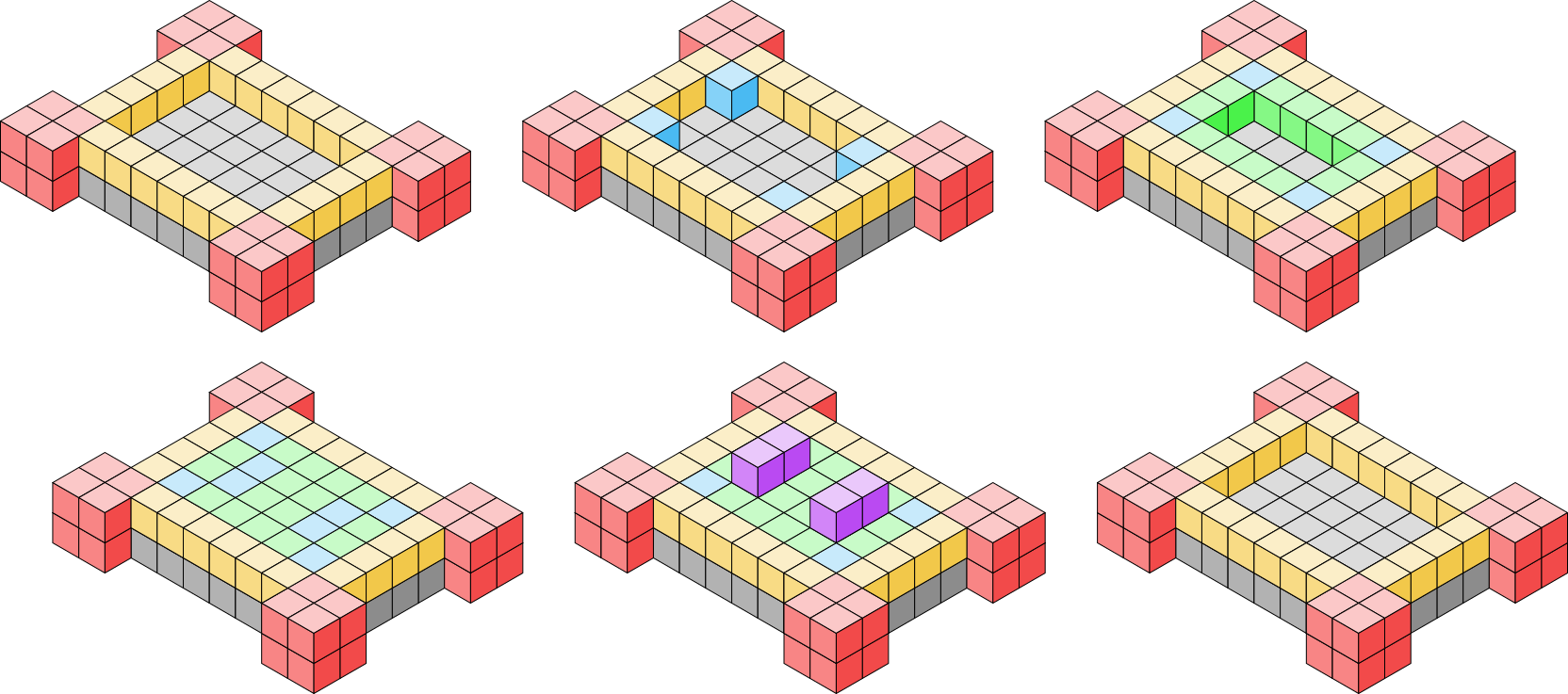

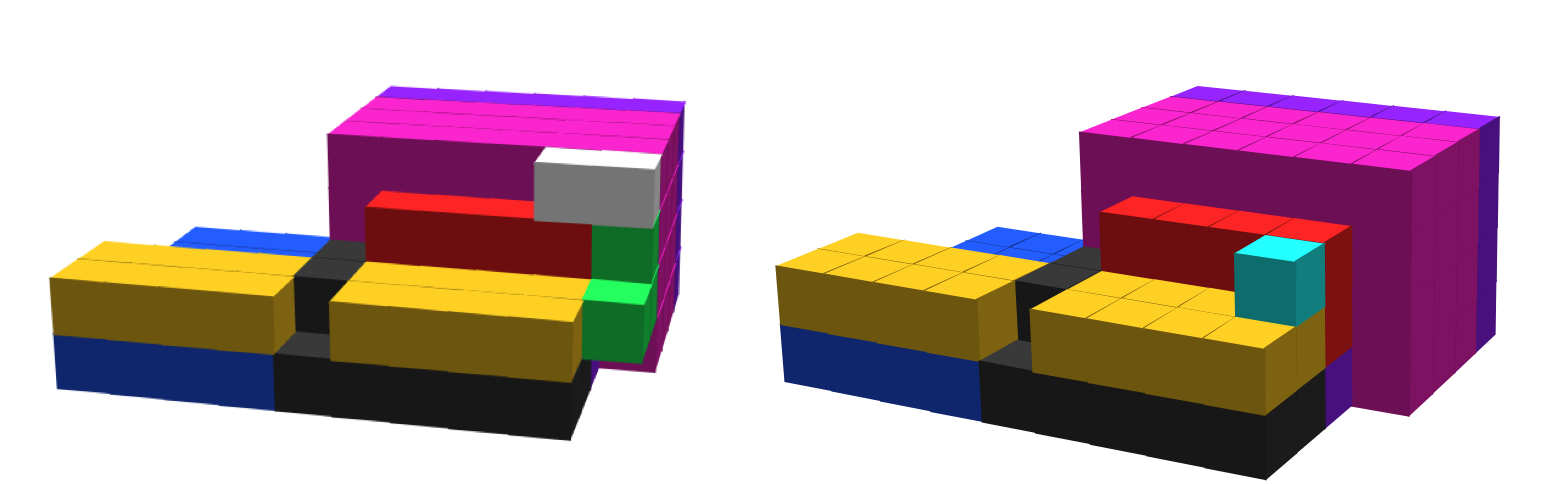

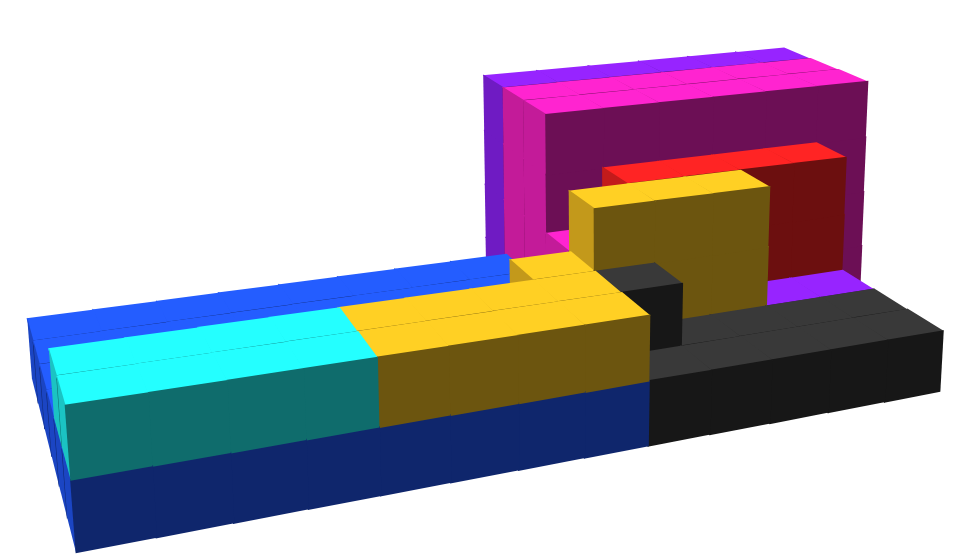

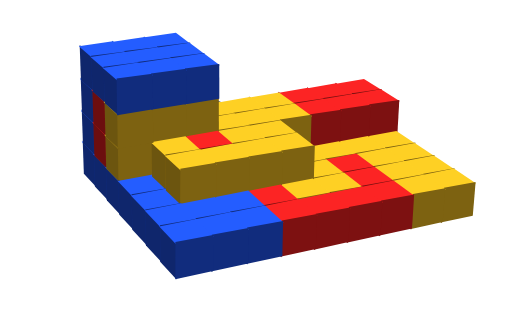

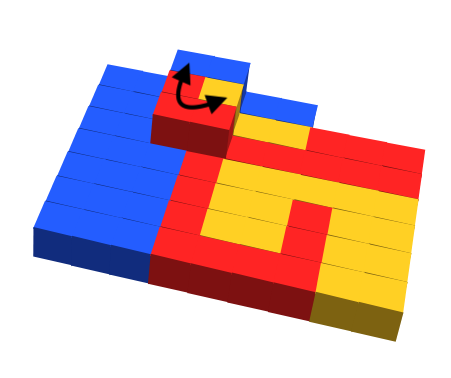

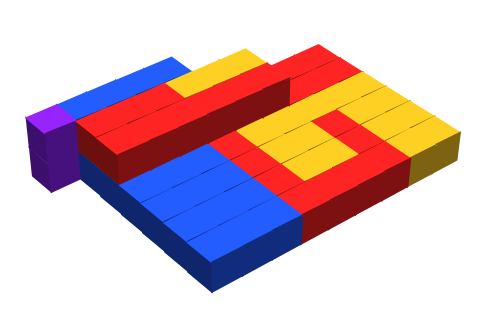

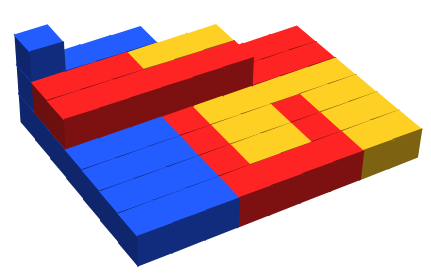

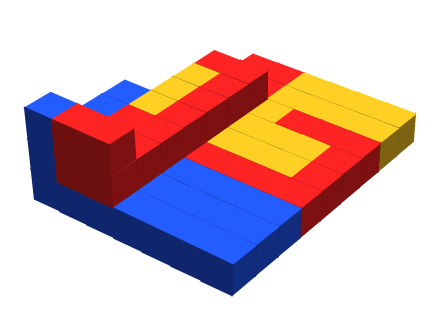

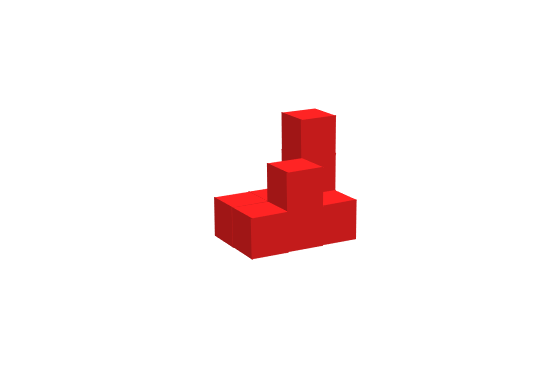

At a high level, the encoding of a shape is generated by a process which visits each voxel in the bounding box sequentially, and transfers the information of whether the voxel is inhabited by a filler tile or a shape tile to a new encoding assembly . The set of all encodings of shapes is where is the encoding of for . The first step in the process is for an encoding corner gadget (see Figure 15) to bind to the corner elected as leader, and then construct a set of helper tiles around the bounding box. Deconstruction is then carried out in slices, where each slice is the set of voxels contained in a 2D subset of the bounding box. The starting voxel contains the tile elected leader (see Figure 14) and the orientation of the binding of the encoding corner gadget arbitrarily defines the orientation of the slices. For ease of explanation, once an orientation has been chosen by the attachment of the encoding corner gadget, we choose the and directions to correspond to the axes along a slice and the direction to be the axis perpendicular to and into the bounding box from the leader. Specifically, each plane of the bounding box constitutes one slice. The end result of the encoding process is a rectangular prism assembly of height 1 where the each tile corresponds to a unique location of the bounding box in , and whose glues represent whether or not each location contains a shape tile (represented by a 1), or empty space inhabited by a filler tile or otherwise (represented by 0). Additionally, information about the order in which tiles were deconstructed is included in for purposes of decoding and defining the width of a row. We note that the tiles in this section obey the careful dissolving property in Section 3.1.3.

3.2.1 Creation of a deconstruction shell

The first step of the encoding process is for an encoding corner gadget (Figure 15), similar in structure to the corner gadgets utilized in the leader election process, to bind to the leader corner. We then treat that corner as the origin of our shape, where the directions of the , , and axes are shown in Figure 16. This reference point and orientation allows us to assign coordinates to each voxel of the bounding box. Of key importance during the deconstruction process is that the deconstructing supertile remains connected with strength 2 at all times. It is given that the shape tiles are connected with strength 2, and filler tiles similarly connect to both shape tiles and each other with strength 2. However, filler tiles are connected to only the 2 tiles which caused their cooperative placement and exterior filler tiles expose only strength 1 glues. To ensure that during the deconstruction process no tiles prematurely disconnect from the bounding box (and to provide additional functionality during the deconstruction process), shell tiles are added which create a shell around the bounding box and utilize the signals demonstrated in Figure 8 to enable strength 2 connections with the exterior-most fill tiles. At the end of the creation of the deconstruction shell (which we will also simply refer to as the ‘shell’), the bounding box will have all tiles on its faces covered, aside from those that are part of the first slice of the bounding box to be encoded. The shell consists of three parts corresponding to tile types: (1) the shell base, tiles which cover one face of the bounding box, allow for communication between tiles in the shell and allow for cooperative binding of recognizer tiles (to be described), (2) shell slices, which cover 3 faces of the bounding box (aside from the tiles that are part of the first slice of the bounding box) and are removed after each slice of the bounding box is encoded, and (3) a cap, which covers the remaining face and allows for the encoding process to sense when it has completed the decoding process.

Shell Base Formation

The growth of the shell base is the first step of process and is initialized from the encoding corner gadget; cooperative growth of shell base tiles begins along the plane, demonstrated in Figure 16. This growth is initiated by the tile of the encoding gadget in the location, which activates glues on its and faces leading to base tiles being able to cooperatively bind with the encoding corner gadget and the bounding box. Once bound to the shape, they activate glues similar to the encoding gadget to continue the binding until no feasible binding sites remain.

Shell Slice Formation

To ensure the shell is complete before the remainder of the encoding process proceeds, the shell growth process proceeds away from the origin in the direction only after shell slice tiles have entirely surrounded an plane of the bounding box. Each shell slice which grows is only a single tile wide. The growth of the first shell slice tile is enabled by the activation of a strength 1 glue on the encoding corner gadget on the tile in the location along its face, and with the adjacent shell base tile. We note that this growth is initiated at the same time as the shell base tiles, however will not begin until a shell base tile is bound to the bounding box in the appropriate location. Cooperative binding sites between the growing shell slice and the face of the bounding box allow for shell tiles to be placed in the direction until reaching the edge of the bounding box, as shown in Figure 17. A shell detector gadget allows for the shell slice tiles to sense they have reached an edge between two faces of the bounding box. For the growth of shell slice tiles to continue in the direction along the adjacent face, a tile must be placed on the face of the most recently placed shell slice tile - the binding of the shell detector gadget to the slice tile and a tile of the bounding box activates a strength 2 glue, allowing a second type of slice tile to bind which contains a complementary strength 2 glue, exposing strength 1 glues along all faces adjacent to tile face containing the strength 2 glue.

Shell growth continues until similarly reaching the edge in the direction, where a shell detector gadget binds and causes the prior process to be repeated. Growth of shell slice tiles then continues in the direction along the face of the bounding box until overlapping with the shell base tiles; when a shell slice tile binds to a shell base tile, a message returns to the shell slice tile which initiated the growth of the current slice. Upon sensing this message, a strength 1 glue is activated on the face of shell tile which initiated growth of the current shell slice layer in the direction. The shell growth process continues until reaching the exterior most slice of the bounding box and cooperative growth is no longer possible.

Shell Cap Formation

At this point, a 4-tile capping gadget binds to an exposed, unique strength 1 glue exposed on the face of outermost slice tile and either a or glue on the bounding box (Figure 19). We note that this unique glue is activated alongside the shell slice growth glue, however geometric hindrances prevent the capping gadget from binding at any point but the edge of the bounding prism. This gadget, similar to the shell detector gadget, causes a strength 2 glue to be activated on the outward-most shell slice tile to place a capping tile. This allows for a final set of capping tiles to enclose the remainder of the bounding prism; once the capping tiles complete the shell, a message is sent back to the encoding corner gadget that the encoding process can begin (Figure 20). The encoding process begins with a signal to deactivate the glues which bind the tiles which provided geometric guidance to the encoding corner gadget and activating a new strength 1 glue, .

3.2.2 Encoding Assembly via Bounding Box Deconstruction

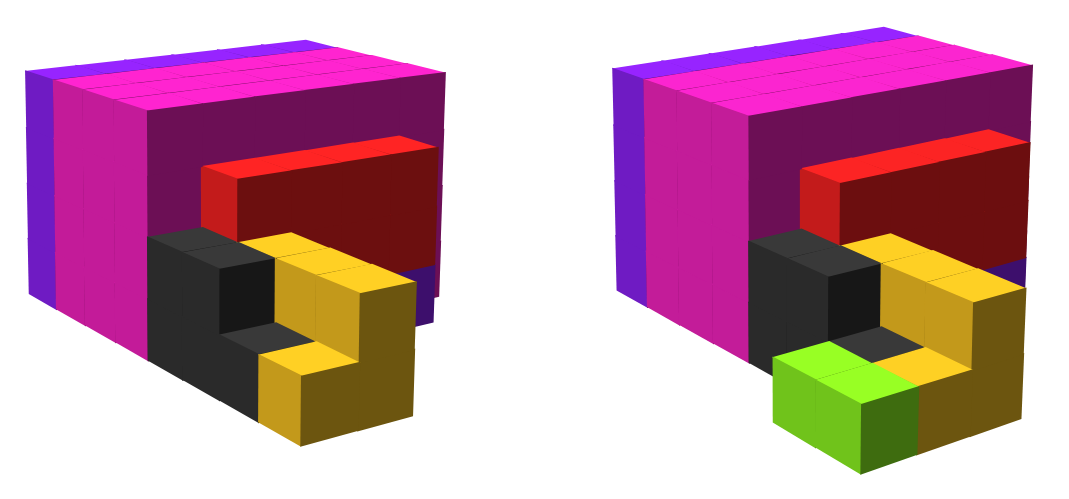

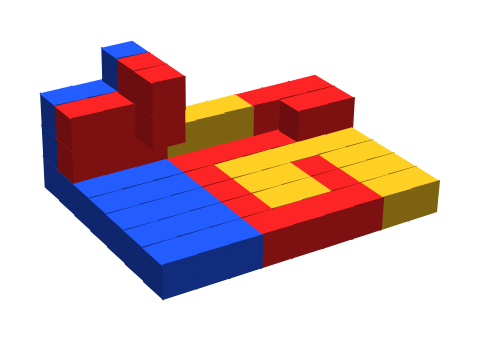

With the deconstruction shell created around the bounding box, we are now able to begin the process of building the encoding structure () by deconstruction. Before continuing into the details of the encoding process, we provide a description of how the information provided by the location of tiles in a bounding box is encoded into binary values. Beginning with the origin point , we read the tile type information for each tile in the first row sequentially by incrementing the -coordinate; for example, the second tile read is in the voxel with coordinates . Once all tiles in the current row have been read, we jump to the next row up. For example, in a bounding box shown by Figure 21, the final location in the first layer is . The next tile encoded is at coordinates . We then encode tiles heading towards the origin; the next voxel encoded in our example encoding would be . Upon arriving at the coordinate (the last of the row moving in this direction) we jump to the next row up, then encoding . By this process of visiting every tile in a slice in a ‘zig-zag’ pattern, we are able to encode the information regarding any slice of a bounding box sequentially.

The very first row of the encoding subassembly contains additional information regarding the direction of the growth in our zig-zag pattern, and as a byproduct we also are able to easily retrieve the width of the rows of tiles. We compare the values in the coordinates between the first tile of a row and the last tile of a row by subtracting the value between the two such that . If a tile is contained in a row where we denote this growth in the positive (‘+’) direction. Alternatively, if we denote this growth in the negative (‘-’) direction. We encode ‘+’ direction growth as a ‘0’, and ‘-’ direction growth as a ‘1’. For example, in Figure 21, the first row begins growth at tile 1, the origin and ends at , leading to . In contrast, the second row begins at and ends at , leading to . We can see that the direction tiles placed in front of row 1 are encoded as 0, and encoded as 1 for row 2. All further slices only add a single tile for each voxel, as the direction for all tiles which have the same value in their tuple is the same (e.g., the tile in which is the second tile placed in the first slice; the tile in is the second tile placed in the second slice).

For simplicity, the differentiation between shape and fill tiles is excluded in remaining figures in this section.

First Slice Deconstruction

To encode the information contained in the first slice of the bounding box, one of four recognizer tiles, , cooperatively bind to a tile in the bounding box and the corner gadget (or the tiles added to the corner gadget, as will be shown shortly). The recognizer tiles detect either a fill tile with glue or a shape tile if the glue is of type . We note that the activation of the glue on the encoding corner gadget allows for only two possible tiles to bind to the origin location. tiles start with active and glues on adjacent edges, tiles start with active and glues on adjacent edges. The two remaining tile types are utilized for ‘-’ direction growth. The tiles contain glues which allow for specific growth patterns unique to the first slice; the recognizer tiles for the remaining slices are demonstrated in Section 3.2.2.

After this binding occurs, 2 sets of signals are activated. First, the binding with the encoding corner gadget causes the activation of a strength 2 glue on the encoding corner gadget which allows for the growth of an additional layer of tiles in the direction adjacent to the encoding gadget, shown in Figure 22. Secondly, signals are sent to the face of tile opposite the bounding prism which allows for growth of two messenger tiles; a strength 1 glue is activated on the face of the outermost tile (Figure 23). Messenger tiles contain glues which allow for the recognizer tiles to pass information regarding the direction of growth and the tile type of the shape voxel which they are adjacent to. This, along with activation of glues from the encoding corner gadget itself allows for cooperative growth of a path along the edge of the encoding corner gadget (Figure 24). Once the growth of tiles reach the tile of the encoding corner gadget located at , cooperative growth halts. An encoding detector gadget (green) is able to bind to the glue on the encoding corner gadget and the outermost encoding tiles placed due to cooperative growth. This binding of the messenger tile with the encoding detector gadget causes the activation of a strength 2 glue which allows for binding with the first tile of the encoding shape along the axis (this tile ends up becoming the nucleation site for decoding as well). Once the first tile of the encoding structure is added, additional tiles cooperatively bind to the tiles of the encoding structure and the shell slice tiles (but not the shell cap tile). This growth is visualized in Figure 25.